75

Reassembly

32 690 03 Rev. E KohlerEngines.com

Install Valve Covers

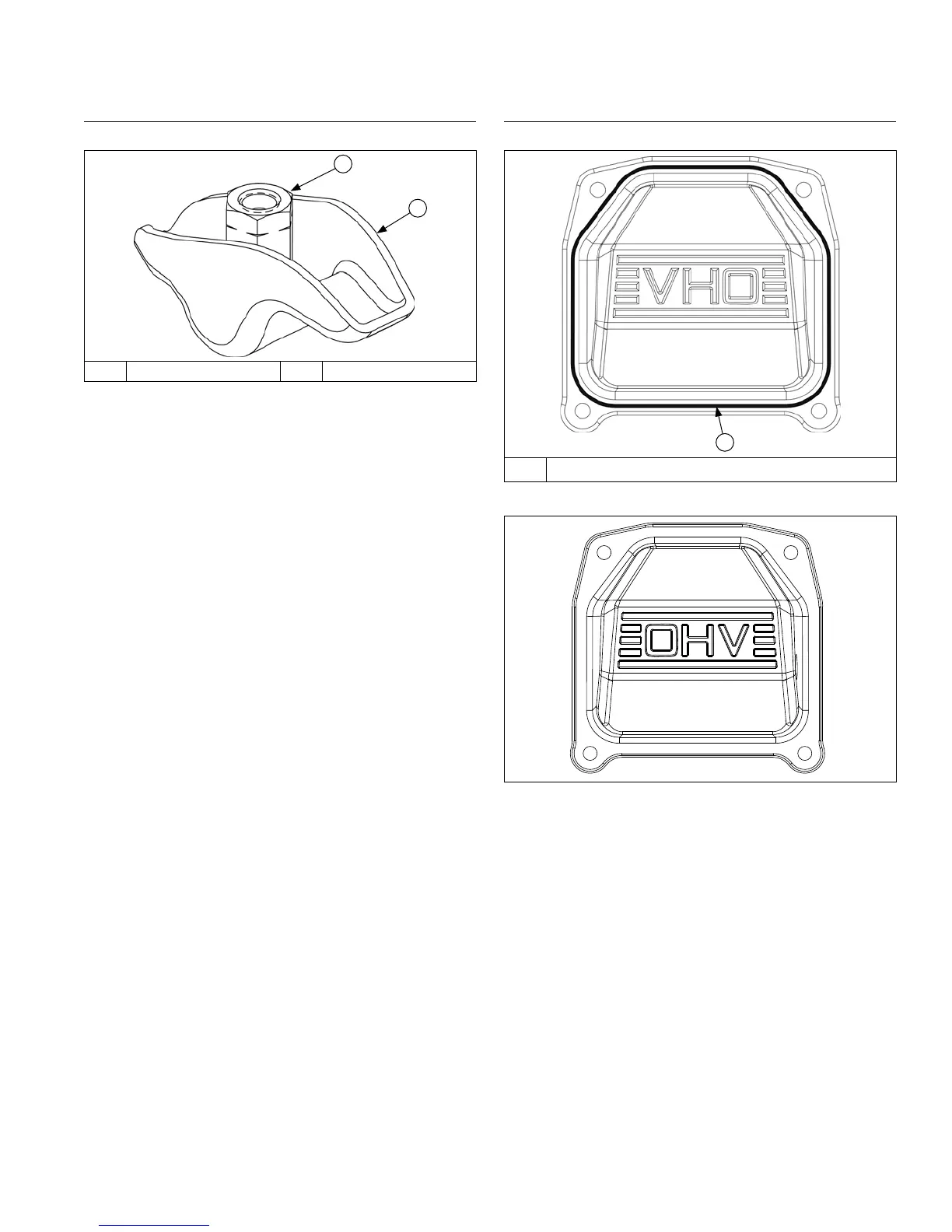

Valve Cover RTV Sealant

A

A RTV Sealant

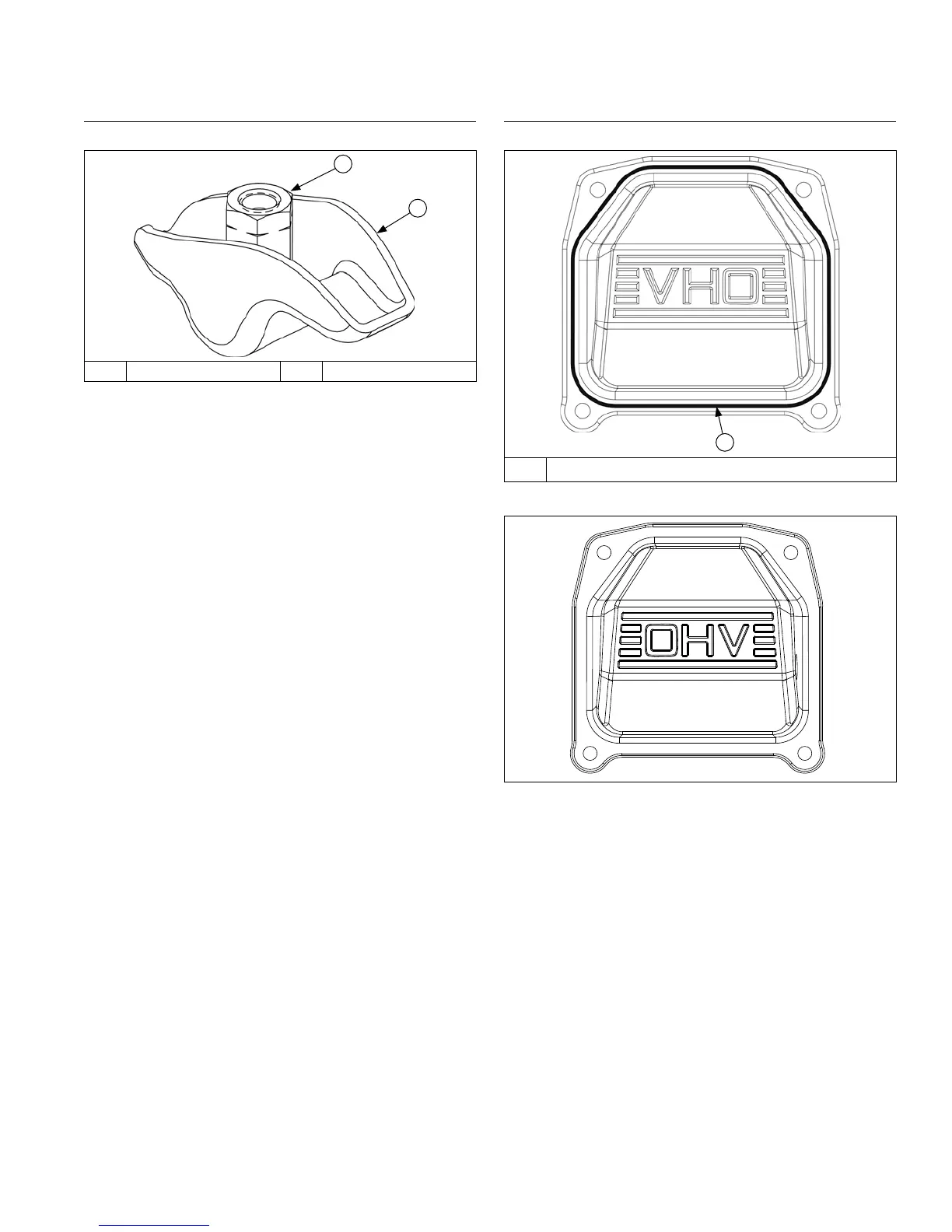

Valve Cover Torque Sequence

1&5 3

2

4

NOTE: Always use fresh sealant. Using outdated

sealant can result in leakage. Refer to Tools and

Aids for information on sealant dispenser.

NOTE: To ensure proper adhesion of sealant to both

sealing surfaces, perform step 3 immediately (5

minutes maximum) after application of RTV.

RTV silicone sealant is used as a gasket between valve

cover and cylinder head. Refer to Tools and Aids for a

listing of approved sealants.

1. Prepare sealing surfaces of cylinder heads and

valve covers. Flatness of sealing surface must be

checked prior to reinstallation. See Disassembly.

2. Apply a 1.5 mm (1/16 in.) bead of sealant to valve

cover as shown.

3. Position covers on cylinder heads. If a pulse style

fuel pump is used valve cover with pulse tting hole

must be installed on side 2. Install screws in each

cover and nger tighten.

4. Torque valve cover fasteners to 9.6 N·m (85 in. lb.),

using sequence shown.

Adjust Valve Clearance

Adjusters Retaining Push Rods

A

B

A Adjuster B Rocker Arm

1. Rotate crankshaft to establish TDC on compression

stroke for cylinder 1.

Check for:

a. Compression will be felt through spark plug hole.

b. Keyway of crankshaft will be aligned with cylinder

1.

c. No rocker arm/push rod movement if crankshaft

is rotated slightly back and forth. If they are

moving, rotate crankshaft 1 full revolution.

2. Insert a 0.127 mm (0.005 in.) feeler gauge between

end of 1 valve and rocker arm. Turn adjuster until a

slight drag is felt. Hold in this position and tighten

setscrew securely. Torque setscrew to 7.9 N·m

(70 in. lb.). After tightening recheck adjustment.

Proper valve clearance is 0.101/0.152 mm

(0.004/0.006 in.).

3. Repeat procedure for other valve on side 1.

4. Viewed from PTO end, rotate crankshaft 270° (3/4

turn) counterclockwise and align crankshaft keyway

with cylinder 2, which now puts cylinder at TDC on

compression stroke.

5. Repeat steps 3-4 for setting valve clearance on side

2.

6. Rotate crankshaft to check for free operation of

valve train. Check for clearance between valve

spring coils at full lift, or bending of push rod(s) can

occur. Minimum allowable clearance is 0.25 mm

(0.010 in.).

Check Assembly

Rotate crankshaft a minimum of 2 revolutions to check

longblock assembly and overall proper operation.

Loading...

Loading...