.

MAINTENANCE

SERVICE PROCEDURE

ADJUST IDLER CLEARANCE

The idler moves forward and backward under external pressure when this happens, side guide and guide plate

become worn.

As they become worn, there is side play in the idler, or the idler turns at an angle, causing the track to come off or

resulting in uneven wear, so adjust as follows.

ADJUSTING IN SIDEWAYS DIRECTION

1.

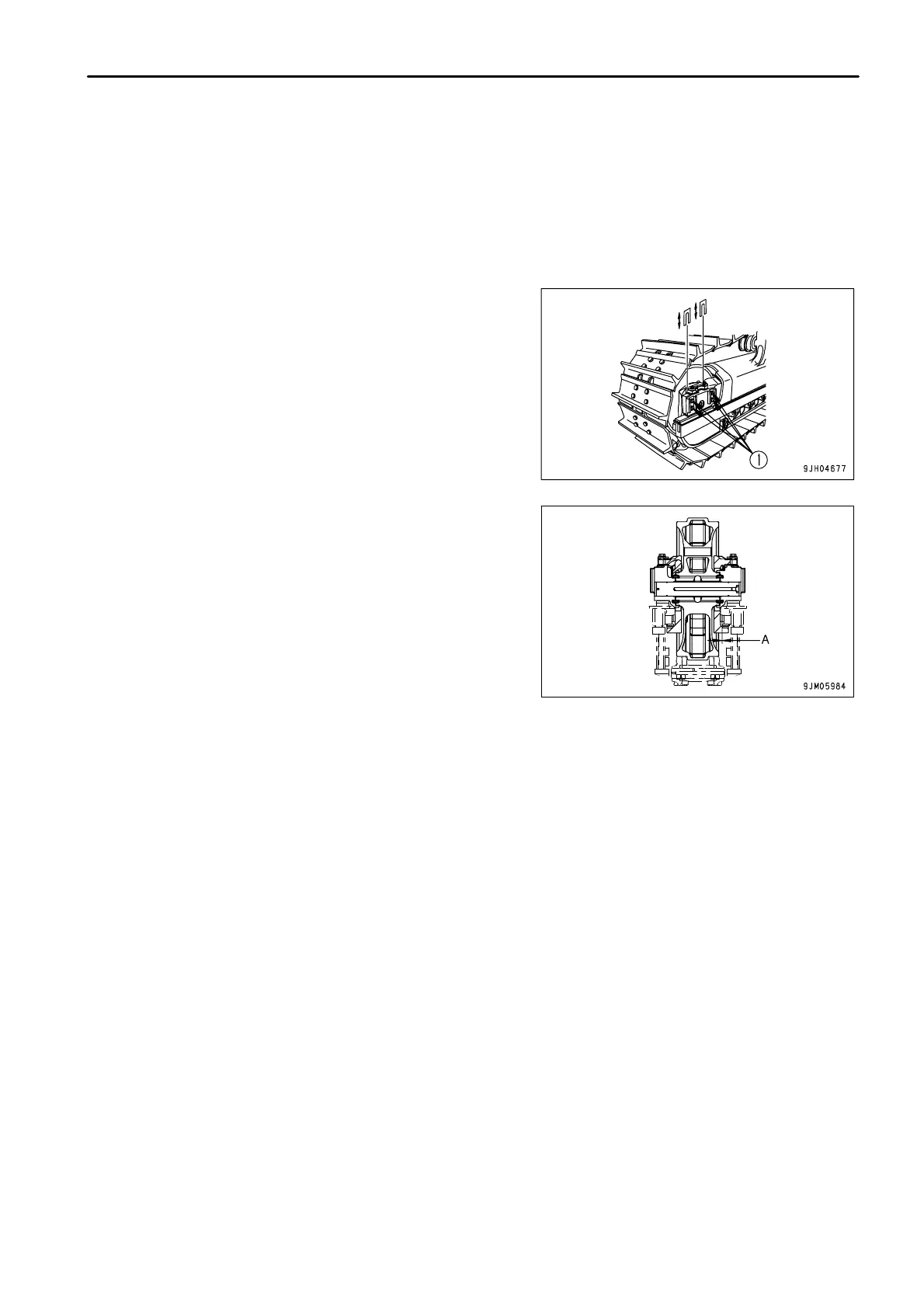

Drive the machine for 8 to 12 m (24.4 to 36.6 ft) on flat ground,

then measure clearance A (4 places: left, right, inside outside)

between the track frame and guide plate.

2.

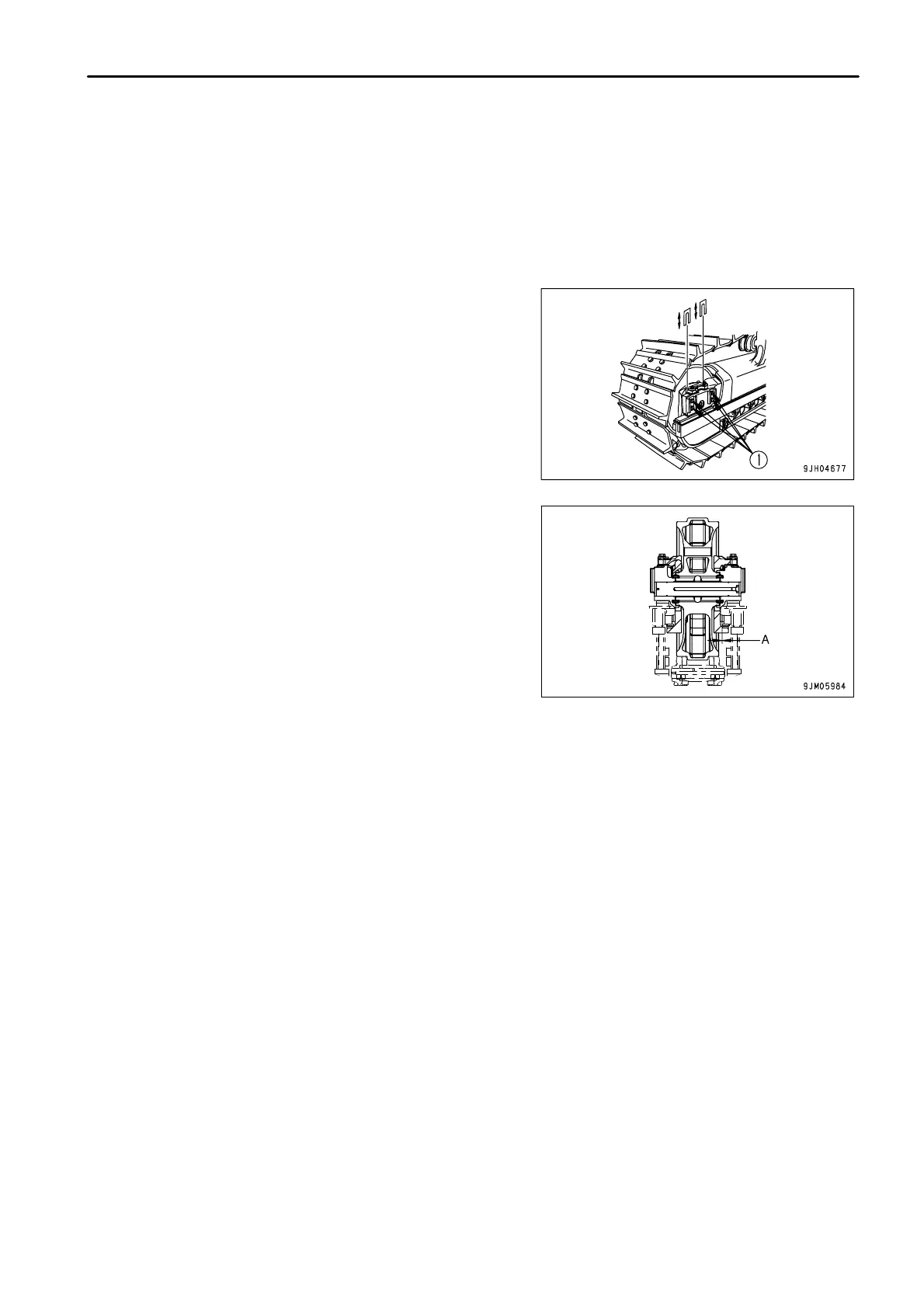

If clearance A is more than 4 mm (0.158 in), remove bolt (1),

then take out shim, and adjust to that the clearance on one side

is less than 0.5 to 1 mm (0.020 to 0.039 in).

REMARK

There are two types of shim

(thickness: 0.5 mm (0.02 in) and 1.0 mm (0.04 in)).

4 - 31

Loading...

Loading...