MAINTENANCE TIGHTENING TORQUE SPECIFICATIONS

PW160-7H VEAM390100 237

TIGHTENING TORQUE SPECIFICATIONS

TIGHTENING TORQUE LIST

CAUTION

If nuts, bolts, or other parts are not tightened to the specified

torque, it will cause looseness or damage to the tightened

parts, and this will cause failure of the machine or problems

with operation.

Pay careful attention when tightening parts.

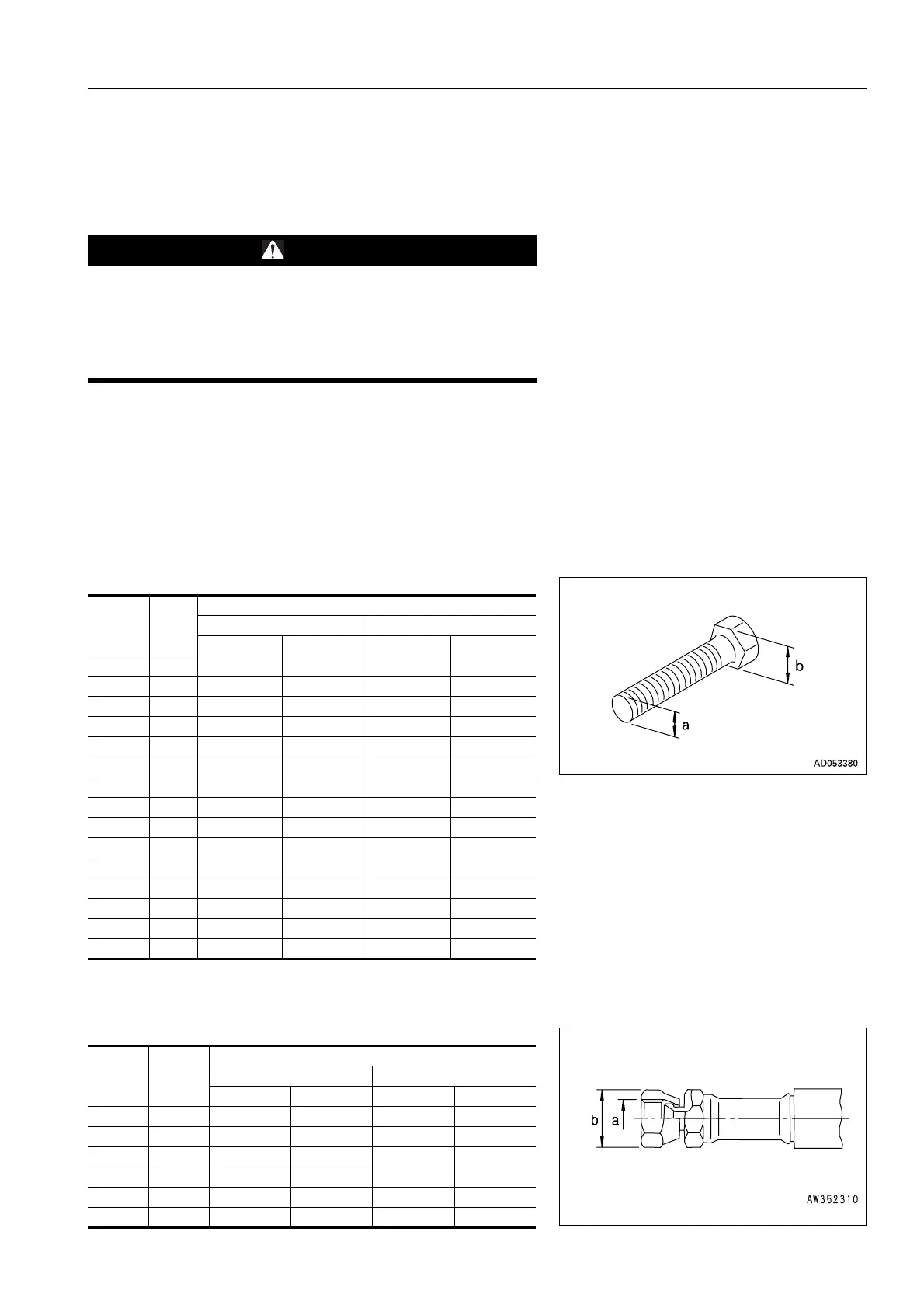

Unless otherwise specified, tighten the metric nuts and bolts to

the torque shown in the table below.

The tightening torque is determined by the width across the flats

of the nut and bolt.

If it is necessary to replace any nut or bolt, use a Komatsu genu-

ine part of the same size as the part that was replaced

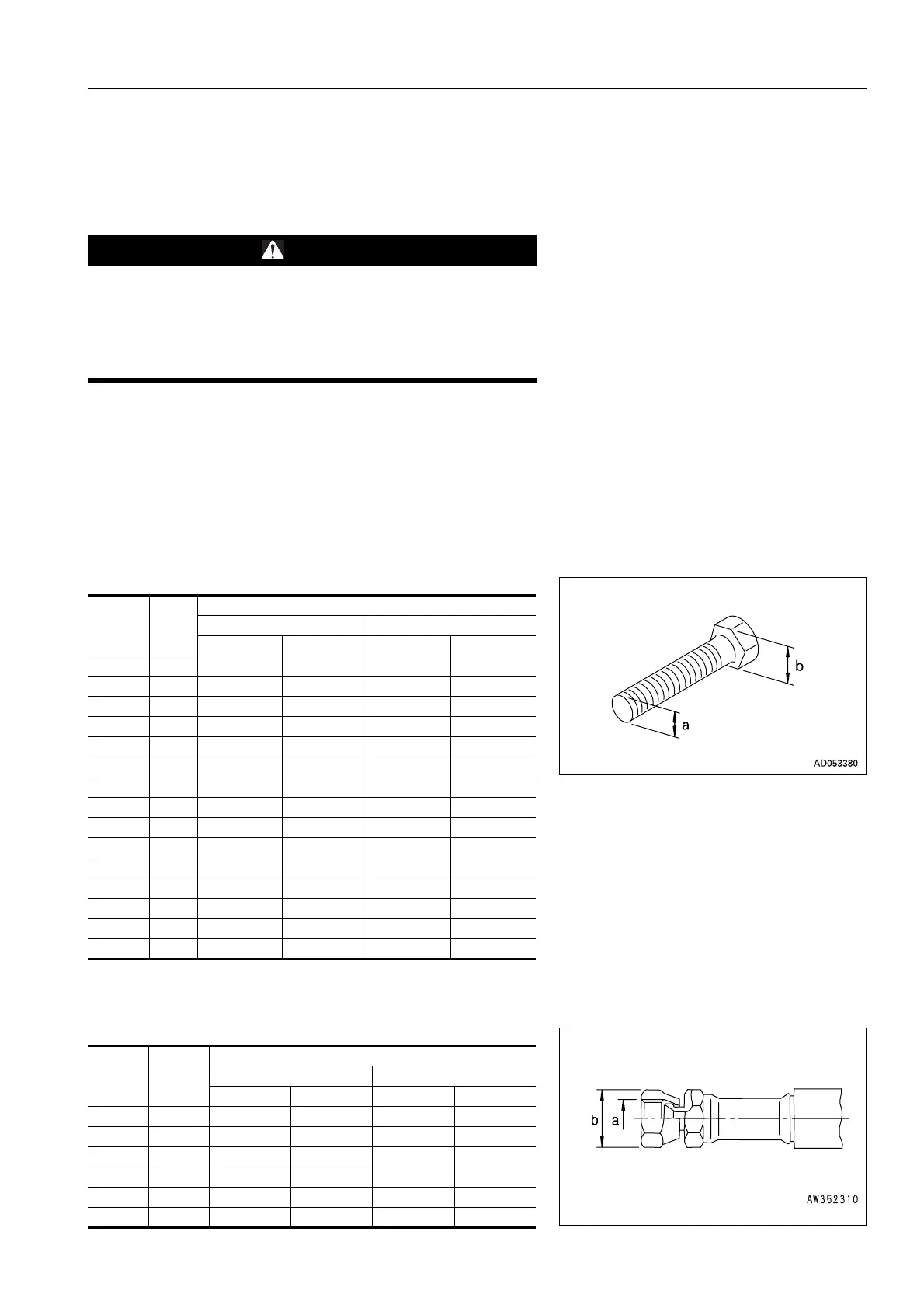

Apply the following table for Hydraulic Hose

.

Thread

diameter a

(mm)

Width

across

flat b

(mm)

Tightening torque

Target value Service limit

N•m kgf•m N•m kgf•m

6 10 13.2 1.35 11.8 - 14.7 1.2 - 1.5

8 13 31 3.2 27 - 34 2.8 - 3.5

10 17 66 6.7 59 - 74 6.0 - 7.5

12 19 11 11.5 98 - 123 10.0 - 12.5

14 22 177 18 157 - 196 16.0 - 20.0

16 24 279 28.5 245 - 309 25.0 - 31.5

18 27 382 39 343 - 425 35.0 - 43.5

20 30 549 56 490 - 608 50.0 - 62.0

22 32 745 76 662 - 829 67.5 - 84.5

24 36 927 94.5 824 - 1030 84.0 - 105.0

27 41 1320 135.0 1180 - 1470 120.0 - 150.0

30 46 1720 175.0 1520 - 1910 155.0 - 195.0

33 50 2210 225.0 1960 - 2450 200.0 - 250.0

36 55 2750 280.0 2450 - 3040 250.0 - 310.0

39 60 3280 335.0 2890 - 3630 295.0 - 370.0

Thread

diameter a

(mm)

Width

across flat

b (mm)

Tightening torque

Target value Service limit

N•m kgf•m N•m kgf•m

14 19 29.4 3.0 27.5 - 39.2 2.8 - 4.0

18 24 78.5 8.0 58.8 - 98.1 6.0 - 10.0

22 27 117.7 12.0 88.3 - 137.3 9.0 - 14.0

24 32 147.1 15.0 117.7 - 176.5 12.0 - 18.0

30 36 215.7 22.0 176.5 - 245.2 18.0 - 25.0

33 41 255.0 26.0 215.7 - 284.4 22.0 - 29.0

Loading...

Loading...