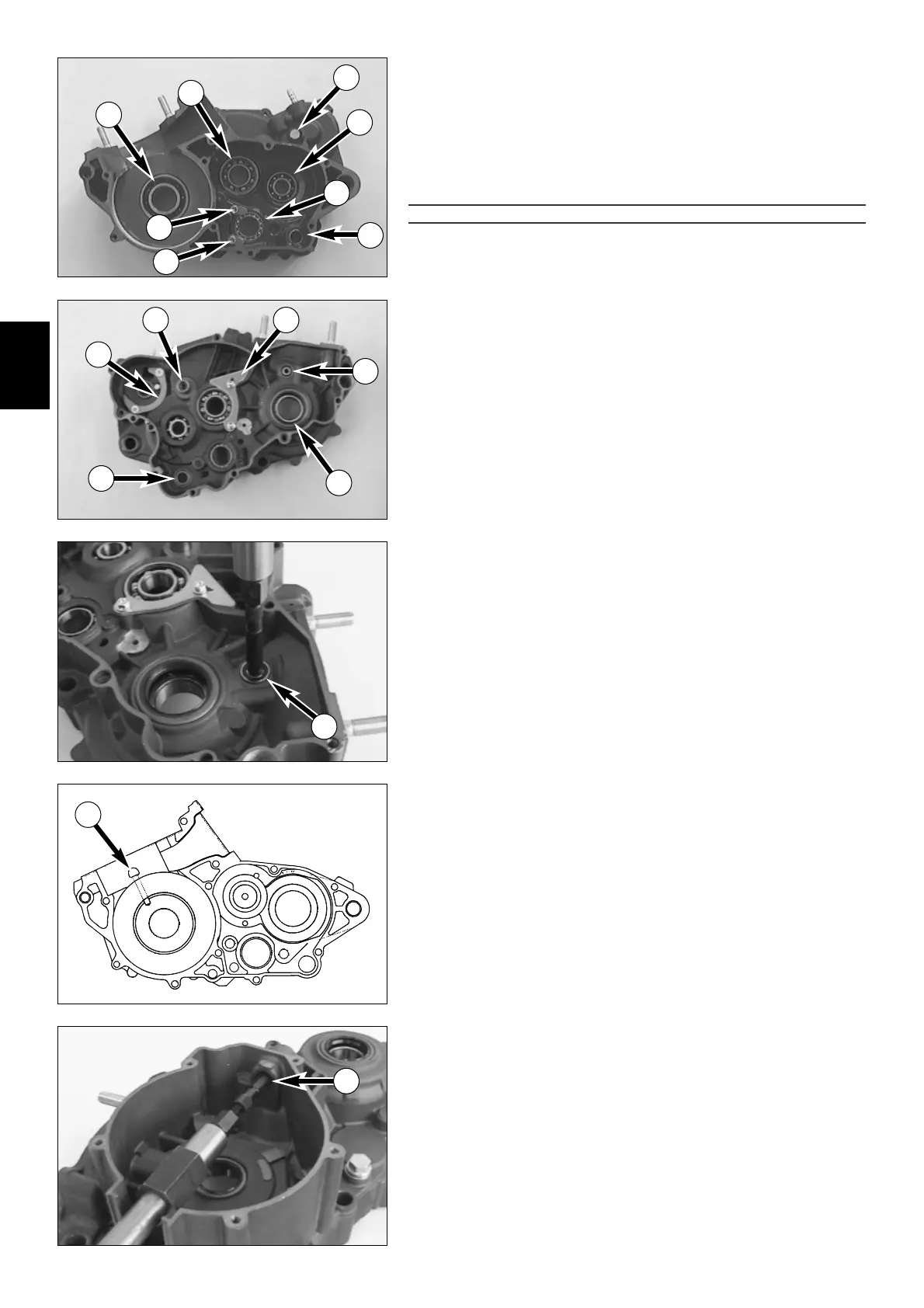

4.1 Right-hand housing half

Heat housing half to 150° C by means of hot plate.

G

ROOVED BALL BEARING OF CRANKSHAFT

1

Press old grooved ball-bearing inwards. Press in new ball bearing to the stop. The

open side of the ball cage must be towards the bottom (outside) of the case.

G

ROOVED BALL BEARING OF MAIN SHAFT

2

Press in new ball bearing from inside up to the stop.

!

CAUTION

!

D

O NOT USE FORCE WHEN PRESSING THE GROOVED BALL BEARING AGAINST THE RETAINING

BRACKET

3

TO AVOID A BENDING OF THE BRACKET, WHICH WOULD RESULT IN EXCESSIVE

AXIAL PLAY OF THE MAINSHAFT

.

G

ROOVED BALL BEARING OF COUNTERSHAFT

4

Press in new grooved ball bearing from downward to the stop. The open side of the

ball cage must be face inwards.

G

ROOVED BALL BEARING OF THE SHIFT ROLLER

5

Remove retaining screw

A

and press bearing inwards. Press in new ball bearing

from inside to the stop and secure retaining screw with Loctite 242.

N

EEDLE BUSHING OF THE SHIFT SHAFT

6

Press old needle bushing inwards, press in new needle bushing flush from the outside.

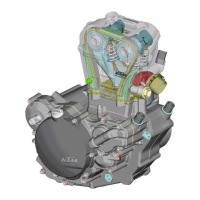

GROOVED BALL BEARING OF CENTRIFUGAL TIMER

7

The bearings usually fall out of their seat of their own accord by knocking the hou-

sinq half on a plane piece of wood when the housing has a temperature of 150° C.

If necessary use a 6 mm internal bearing extractor and guide hammer (see illustra-

tion). Press in new grooved ball bearing to the stop.

B

EARING BOLT KICKSTARTER INTERMEDIATE GEAR

8

Experience has shown that it is never necessary to replace the bearing bolt. It is not

recommended to mount a used bearing bolt in a new housing half, as it is practically

impossible to remove it without causing damage.

K

ICKSTARTER RELEASE PLATE

9

When replacing the release plate, secure the flat-head screws with Loctite 242.

C

RANKSHAFT SEAL RING

bk

Press in new shaft seal ring from the outside, with sealing lip facing inward, until

flush.

S

TOP SCREW KICKSTARTER

bl

When mounting the stop screw, it must be secured with Loctite 242. Do not forget

new copper seal ring.

R

ETAINING BRACKET

3

When replacing the retaining bracket, the two collar screws are to be secured with

Loctite 242.

Finally check clear passage of the crankshaft ball bearing lubrication bore

S

.

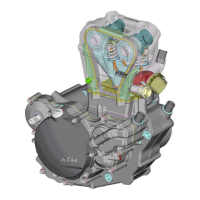

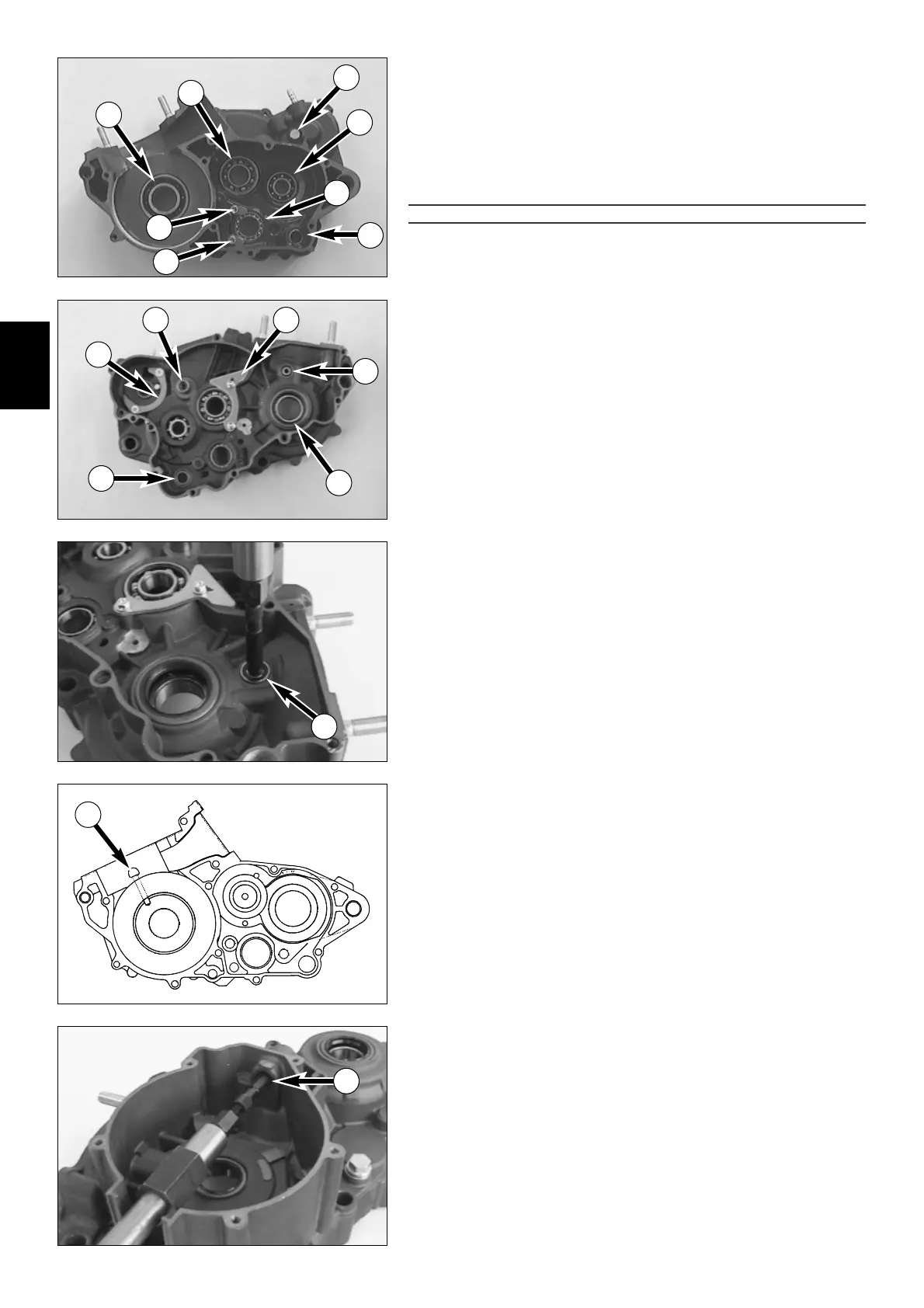

4.2 Left-hand housing half

NEEDLE BUSHINGS OF CLUTCH RELEASE

B

Remove seal ring from bore.

Knock needle bushings out of bore using a 12-16 mm extractor and guide hammer (see

illustration). Press in new needle bushings and seal ring in succession to the stop.

4

7

S

B

8

9

6

10

3

7

1

2

4

6

11

5

A

A

Loading...

Loading...