6

3

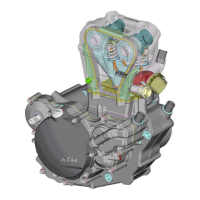

6.4 Checking the capacitor

– Discharge the capacitor by bridging the two terminals with a screwdriver and

remove.

– Connect the negative pole of a 12V battery with the negative terminal of the

capacitor. The connection between the positive pole of the battery and the posi-

tive terminal of the capacitor (marked +) is made with a test lamp

3

.

– When the power circuit is closed, the test lamp must begin to light up. As capa-

citor charging increases, the brightness of the test lamp must decrease.

–

The test lamp must go out after 0,5-2 seconds (depending on the lamp capacity).

–

If the test lamp does not go out or does not light up at all, the capacitor is faulty.

!

CAUTION

!

D

ISCHARGE THE CAPACITOR BEFORE AND AFTER EACH TEST.

W

HEN INSTALLING THE CAPACITOR, MAKE SURE THAT THE TERMINALS ARE CONNECTED IN

ACCORDANCE WITH THEIR MARKINGS

(CONNECT RED/WHITE CABLE TO + TERMINAL)

6.5 Ignition coil (SEM)

As this ignition coil uses electronic components, you are advised not to use con-

ventional measuring instruments. An accurate function test can only be carried out

on an ignition test bench.

6.6 Ignition coil (Kokusan)

– Disconnect all cables and remove the spark plug connector.

– Use an ohmmeter to measure the following values.

NOTE: THE INDICATED SETPOINT VALUES CORRESPOND TO A TEMPERATURE OF 20° C.

R

EPLACE THE IGNITION COIL IF THE MEASURED VALUES DEVIATE SIGNIFICANTLY FROM THE SET-

POINT VALUES.

6.7 CDI unit

Check the cables and plug and socket connections of the CDI unit.

The CDI unit function can only be checked on an ignition test bench.

!

CAUTION

!

N

EVER USE A COMMERCIAL MEASURING DEVICE TO CHECK THE CDI UNIT. COMMERCIAL MEA-

SURING DEVICES CAN DESTROY HIGHLY SENSITIVE ELECTRONIC COMPONENTS.

RESISTANCE

0,425 – 0,575 Ω

10,8 – 16,2 kΩ

MEASUREMENT

primary coil

secondary coil

CABLE COLOURS

blue/white – ground

blue/white – ignition wire

3

Loading...

Loading...