Loading...

Loading...

Do you have a question about the KTM 400 and is the answer not in the manual?

| Transmission | 6-speed |

|---|---|

| Engine | Single-cylinder, 4-stroke |

| Starter | Electric |

| Cooling System | Liquid-cooled |

| Front Suspension | WP USD |

| Rear Suspension | WP |

| Front Brake | Single disc |

| Rear Brake | Single disc |

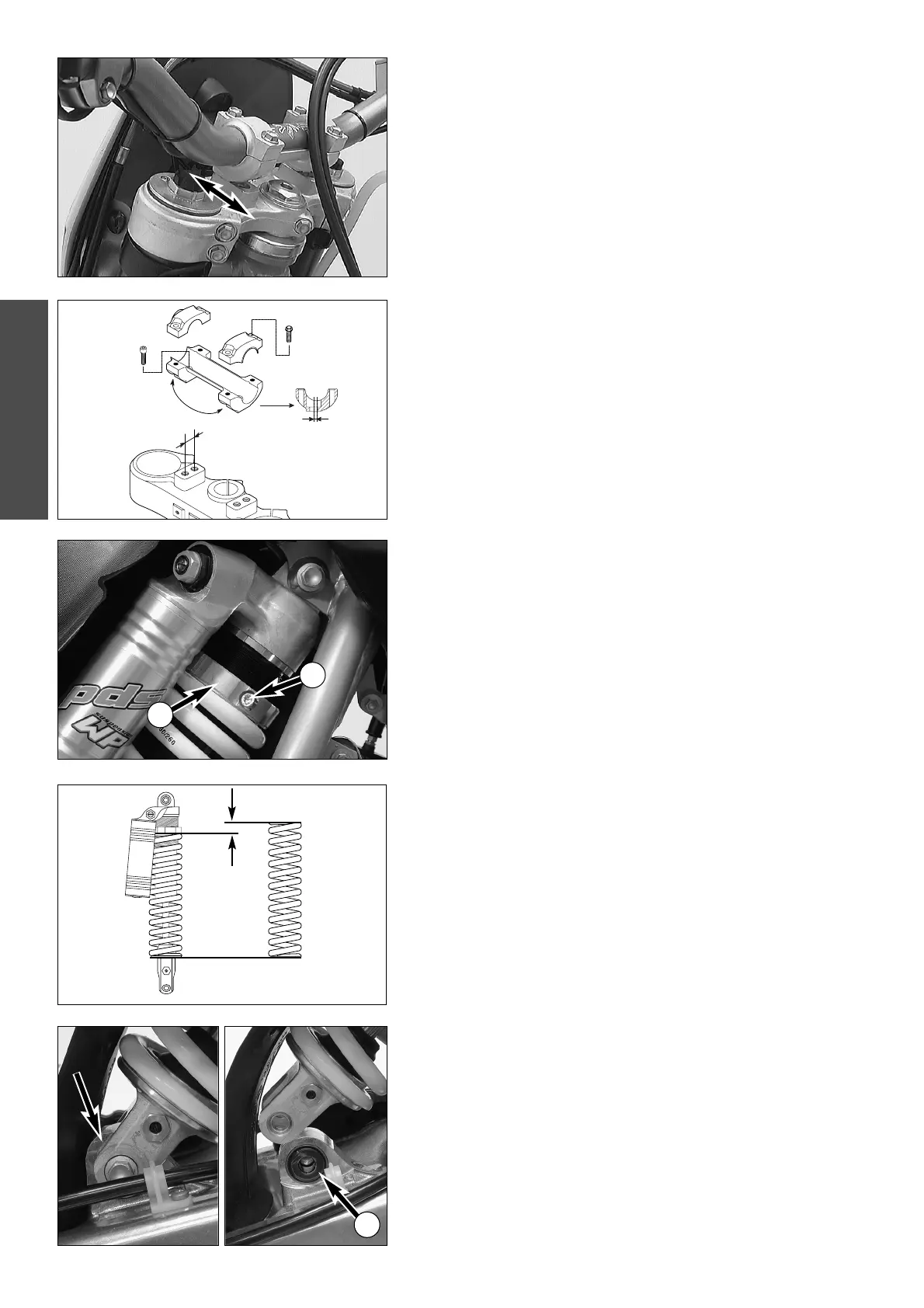

How to adjust the fork's compression and rebound damping.

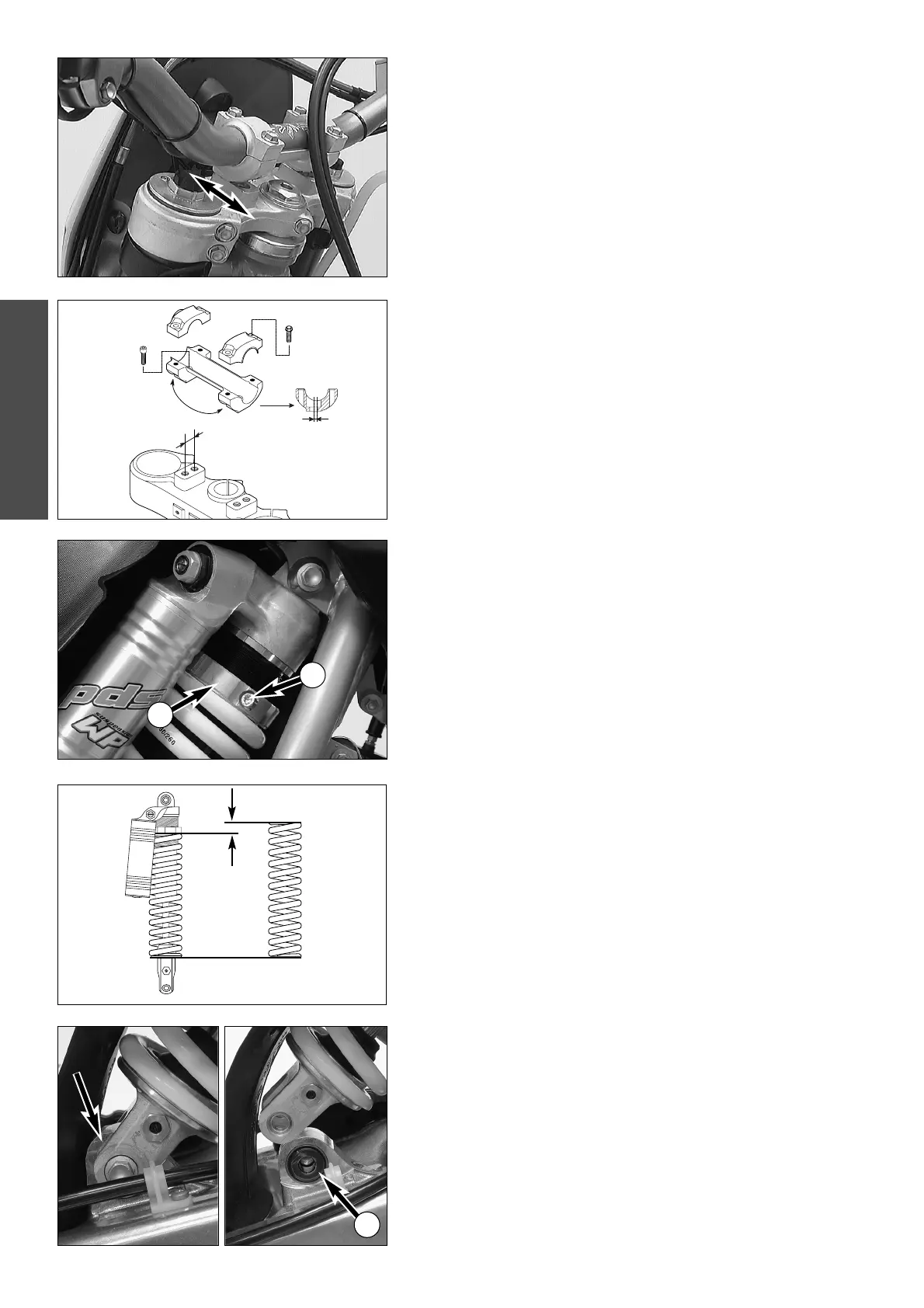

Adjusting compression and rebound damping on shock absorbers.

A checklist of critical inspections before riding.

Guidance for first rides and engine break-in.

Steps for starting the engine in various states.

How to begin riding and change gears smoothly.

Proper use of brakes and associated safety warnings.

Safe procedures for stopping the motorcycle and parking it.

Key maintenance tasks recommended for professional service.

Essential checks riders should perform regularly.

Details on brake calipers, pads, discs, fluid, and safety.

Checking coolant level and bleeding the cooling system.

Selecting and changing engine oil and filters.

Detailed engine technical data and basic carburetor settings.

Chassis data, fork/shock adjustments, and torque specifications.

Specifications for assembly clearances and wear limits.