1 ENGINE

81700'82100·82400 W$M, 11770

Fuel

Tightness

of

Pump Element

1.

Remove the injection pipes and

glow

plugs, and install the

pressu

re

tester.

2.

With

the

speed

control lever at the full injection position,

turn

the

crankshaft counterclockwise (facing the flywheel).

3.

If

the

pressure does

not

build

up

to

the

fuel

injection

pressure, replace the delivery valve

with

new one and test

again.

4.

If

the pressure does

not

built

up more than the fuel injection

pressure, replace the injection pump assembly.

II1II

IMPORTANT

CD

After

replacing only pump element, the amount

of

injection

should

be

adjusted on a specified test bench.

Fuel

Tightness

of

Delivery Valve

1.

The

delivery valve

is

checked in the

same

way

as

the pump

element. Turn the flywheel counterclockwise

to

make

the

pressure gauge indicate

14.7

MPa

(150 kgf/cm

2

,

2133 psi).

2.

Set

the

FI mark on

the

flywheel

of

the

cylinder being

checked

to

the

position

at

90° clockwise

from

the

punch

mark on the rear end plate. (This lowers the pressure inside

the

delivery chamber)

3.

If

it

takes

the

pressure five

seconds

or

more

to

drop

from 14.7

MPa

(150 kgf/cm

2

,

2133

psi)

to

13.7

MPa

(140 kgf/cm

2

,

1991

psi)

the delivery valve

can

be

used.

4.

If

the

measured 'value stays

below

the

allowable

limit,

replace the pump assembly

or

the delivery valve.

Fuel

tightness

of

981

KPa

(10 kgf/cm

2

,

142

psi)

of

delivery valve

Allowable

limit

pressure drop from injection

pressure

for

5

sec.

or

more

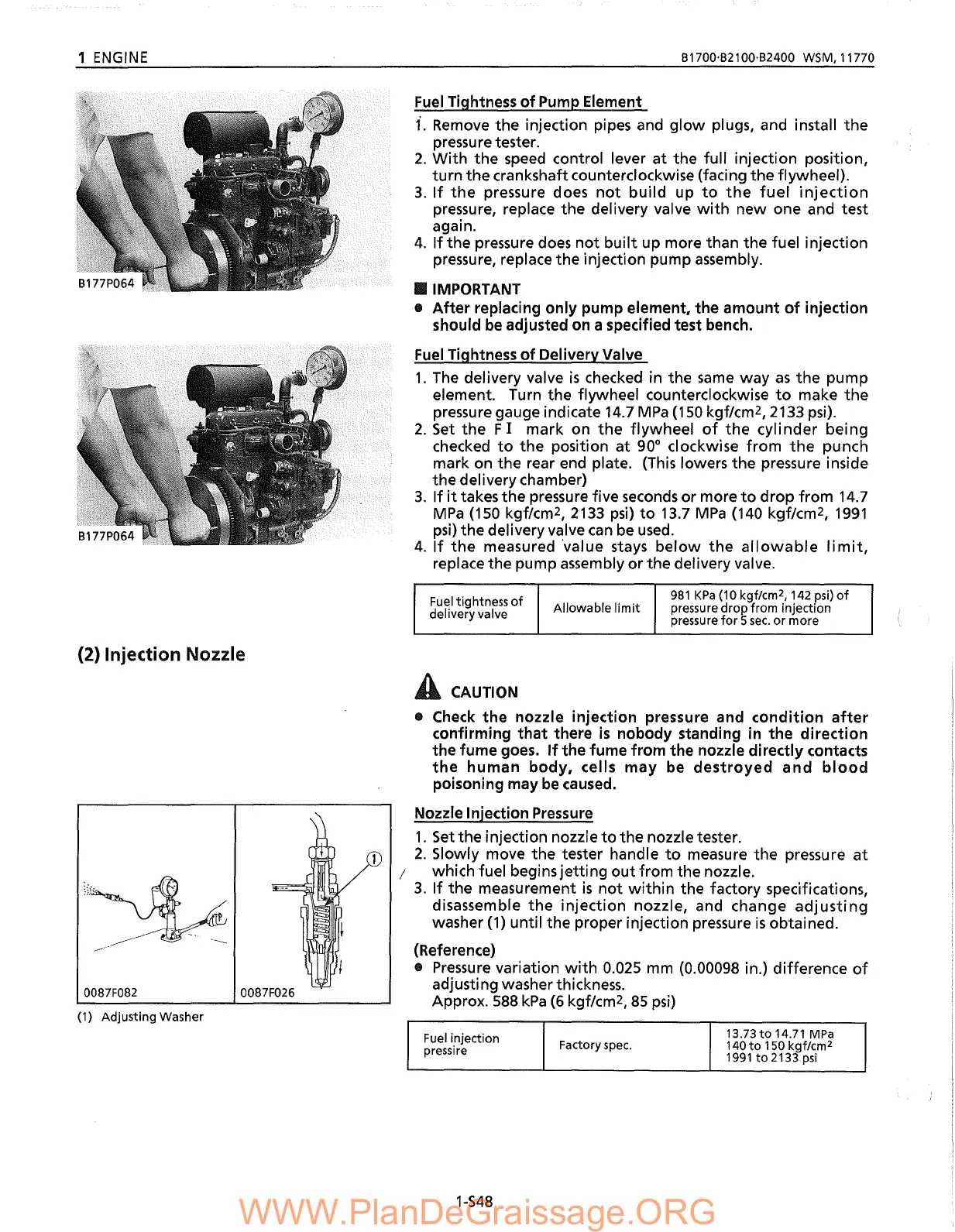

(2) Injection Nozzle

0087F082 0087F026

(1)

Adjusting Washer

A

CAUTION

.. Check

the

nozzle

injection

pressure and

condition

after

confirming

that

there

is

nobody standing in

the

direction

the fume goes.

If

the fume

from

the nozzle directly contacts

the

human

body,

cells

may

be

destroyed

and

blood

poisoning may

be

caused.

Nozzle Injection Pressure

1.

Set

the injection nozzle

to

the nozzle tester.

2.

Slowly move the tester handle

to

measure the pressure

at

/ which fuel begins

jetting

out

from the nozzle.

3.

If

the measurement

is

not

within

the factory specifications,

disassemble

the

injection

nozzle, and change

adjusting

washer

(1)

until the proper injection pressure

is

obtained.

(Reference)

CD

Pressure

variation

with

0.025

mm

(0.00098 in.) difference

of

adjusti ng washer thickness.

Approx.

588

kPa

(6

kgf/cm

2

,

85

psi)

Fuel

injection

13.73

to

14.71

MPa

pressire

Factory

spec.

140

to

150 kgf/cm

2

1991

to

2133

psi

1-S48

Loading...

Loading...