DAILY CHECK

For your own safety and maximum service ·ufe: at the

machine, make a thorough daily inspectiofr:

beforQ: ·

operating the machine or starting the engine. · · · · · · •.

A CAUTION

To avoid personal injury:

• Be sure to check and service the tractor~ on a

firm, flat and level surface with the . engine -

stopped and the parking brake ·

uON." · and

implements lowered to the ground. ·

■

Walk

Around Inspection

Look around and under the tractor for such it~ms as loose

bolts, trash build-up, oil or coolant leaks, br.oken or worn

parts.

■

Checking

and Refuelihg

A CAUTION

ef

To avoid personal injury:

• Do not smoke while refueling.

• Be sure to stop the engine and remove the key

before refueling.

To avoid allergic skin reaction:

• Wash hands immediately after contact with

diesel fuel.

1. Turn the key switch to "ON", check the amount of fuel

by fuel gauge.

2. Fill fuel tank when fuel gauge shows 1 /4 or less fuel in

tank.

3. Use grade No.2-Diesel fuel at temperatures above

-10°C (14°F).

Use grade No.1-Diesel fuel at temperatures below

-10°C (14°F).

~

.

i.~---

'.t·

PERIODIC SERVICE 37

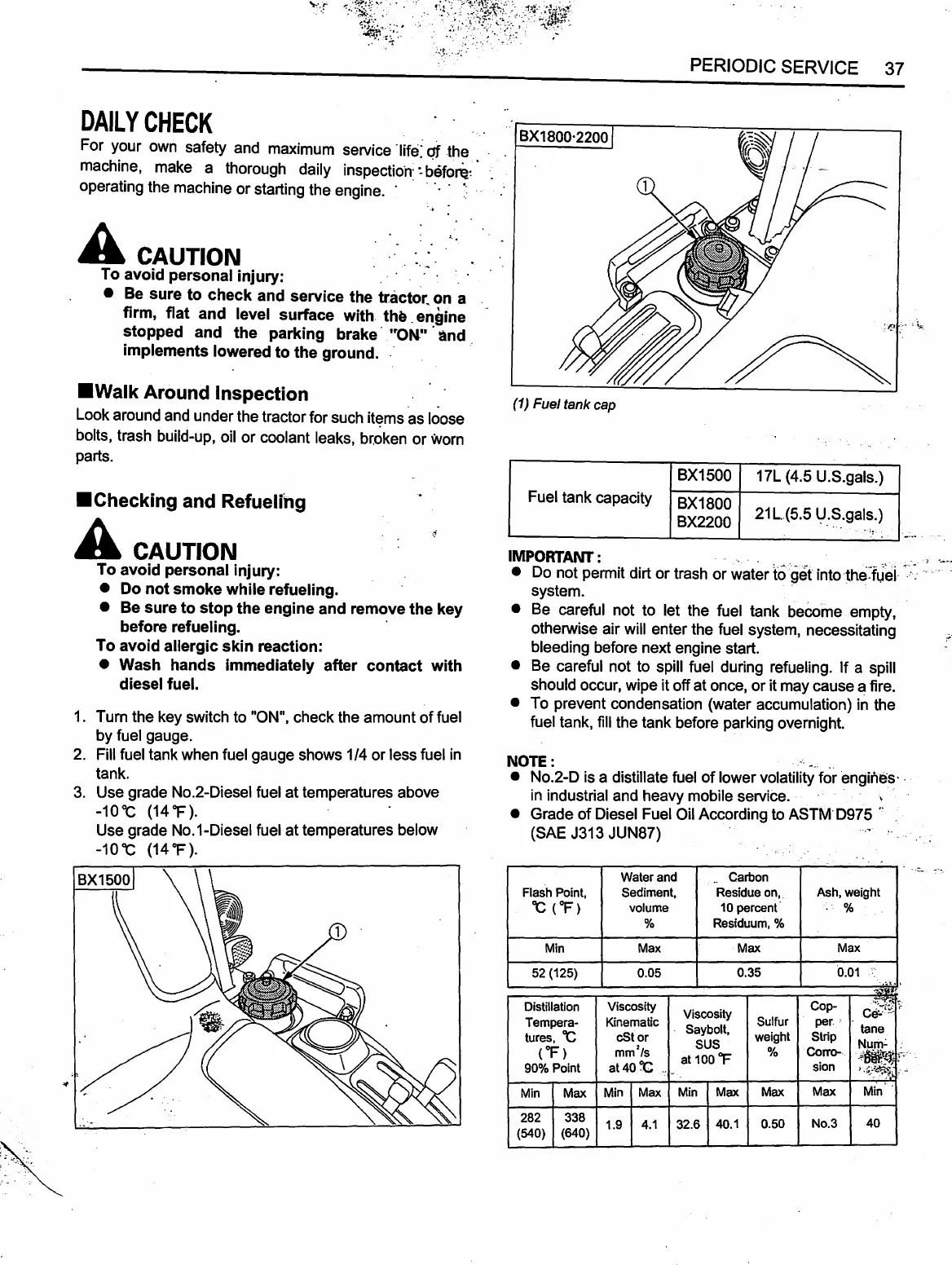

.. BX1800·2200

:·~ '/ .. ; \t..:

~

(1) Fuel tank cap

BX1500

17L (4.5 U.S.gals.)

Fuel tank capacity

BX1800

21L(5.5

Y:~ .. gals.)

BX2200

.. , ...

IMPORTANT: · · -. · ..

~

._ _ _ __ :•,, ~.-

• Do not permit dirt or trash or water

fo get into·the.f1,1el .:_.

system. · .

• Be careful not to let the fuel tank become empty,

otherwise air will enter the fuel system, necessitating

bleeding before next engine start.

• Be careful not to spill fuel during refueling. If a spill

should occur, wipe it off at once, or it may cause~ fire.

• To prevent condensation (water accumulation) in the

fuel tank, fill the tank before parking overnight.

NOTE: -....

• No.2-D is a distillate fuel of lower volatility for ·engines· -

in industrial and heavy mobile service.

• Grade of Diesel Fuel Oil According

to ASTM 0975 •:

(SAE J313 JUN87)

Water and

..

Carbon

Flash Point, Sediment, Residue on,

Ash, weight

°C(°F) volume 10 percent %

% Residuum,%

Min Max Max

Max

52 (125) 0.05

0.35 0.01

"T.,,1

~~,-r

Distillation

Viscosity

Viscosity

Cop-

c;3;~

Tempera-

Kinematic

Saybolt,

Sulfur

per.'

tane

tures,

°C

cStor

SUS

weight Strip

Num.:

(OF)

mm

2

/s

at 100

°F

%

Corro-.

-~M~:

90% Point

at40t ..

-

sion

,.;;,;~1,

Min Max

Min

Max Min Max

Max

Max

Min

282

338

1.9

4.1

(540)

(640)

32.6

40.1

0.50

No.3

40

Loading...

Loading...