Page 9

Expansion Valve Systems

Charging Using the Approach Method

TXV Systems − Outdoor Temp. >

65_F (18_C)

IMPORTANT

The following procedure requires accurate read

ings of ambient (outdoor) temperature, liquid

temperature and liquid pressure for proper

charging. Use a thermometer with accuracy of +

2

°F (+

1.1°C) and a pressure gauge with accuracy

of +

5 PSIG ( +34.5 kPa).

When an expansion valve system is being charged when

the outdoor ambient temperature is 65_F (16_C) or above,

it is best to charge the unit using the approach method.

Subtract the outdoor ambient temperature from the liquid

line temperature to determine the Approach temperature.

(Liquid Line _F (_C) − Outdoor Ambient _F (_C) = Ap

proach Temperature.) The resulting difference (Approach

temperature) should agree with the values given in table 3.

If not, add refrigerant to lower the approach temperature or

recover refrigerant from the system to increase the ap

proach temperature.

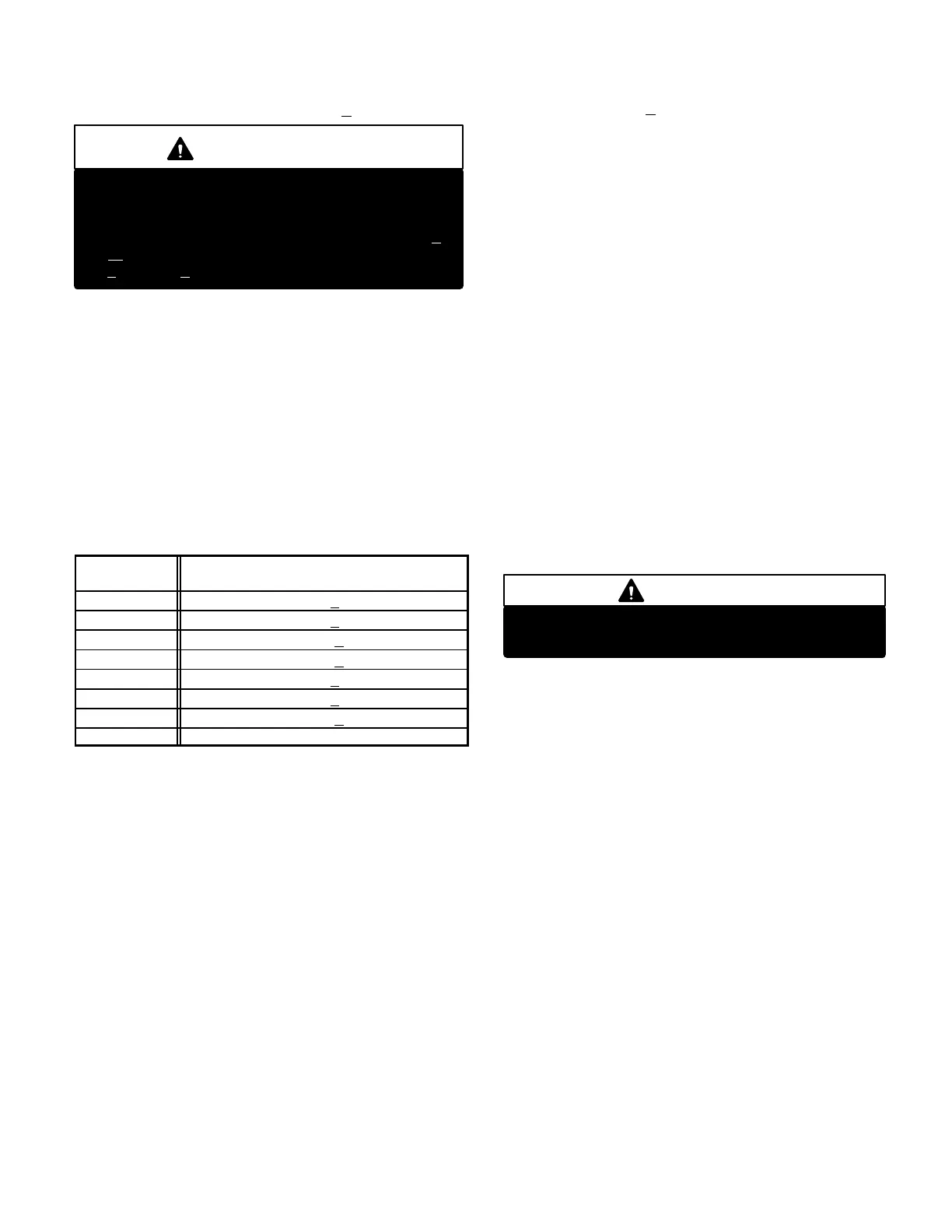

Table 3

Approach Temperatures

(TXV Systems Only)

Model No.

Approach Temperature

Liquid Line − Outdoor Ambient _F (_C)

13ACC−024 9 (5) + 1

13ACC−030 6 (3) + 1

13ACC−036 10 (6) + 1

13ACC−037 12 (7) + 1

13ACC−042 8 (4) + 1

13ACC−048 7 (4) + 1

13ACC−047 10 (6) + 1

13ACC−060 12 (7) + 1

NOTE − For best results, use the same digital thermometer to check

both outdoor ambient and liquid temperatures.

Charging Using the Subcooling Method

TXV & Fixed Orifice Systems Outdoor Temp.

>

65_F (18_C)

If you charge a fixed orifice system when the outdoor ambi

ent is 65_F (18_C) or above, use the subcooling method to

charge the unit.

1 − With the manifold gauge hose still on the liquid service

port and the unit operating stably, use a digital ther

mometer to record the liquid line temperature.

2 − At the same time, record the liquid line pressure reading.

3 − Use a temperature/pressure chart for HCFC22 to de

termine the saturation temperature for the liquid line

pressure reading.

4 − Subtract the liquid line temperature from the saturation

temperature (according to the chart) to determine sub

cooling. (Saturation temperature − Liquid line tem

perature = Subcooling)

5 − Compare the subcooling value with those in table 4. If

subcooling is greater than shown, some refrigerant

must be recovered. If subcooling is less than shown,

some refrigerant must be added.

E − Oil Charge

Refer to compressor nameplate.

IV − MAINTENANCE

Make sure all power is disconnected before

beginning electrical service procedures.

DANGER

At the beginning of each cooling season, the system should be

cleaned as follows:

A − Outdoor Unit

1 − Clean and inspect condenser coil. (Coil may be

flushed with a water hose).

2 − Visually inspect all connecting lines, joints and coils for

evidence of oil leaks.

NOTEOutdoor fan motors are permanently

lubricated.

B − Indoor Coil

1 − Clean coil if necessary.

2 − Check connecting lines and coil for evidence of oil

leaks.

3 − Check condensate line and clean if necessary.

C − Indoor Unit

1 − Clean or change filters.

2 − Bearings are prelubricated and need no further oiling.

3 − Check all wiring for loose connections.

4 − Check for correct voltage at unit.

5 − Check amp−draw on blower motor.

Unit nameplate_________Actual_________.

Loading...

Loading...