Page 10

3 − Replace stem cap. Tighten finger tight, then tighten an

additional 1/6 turn.

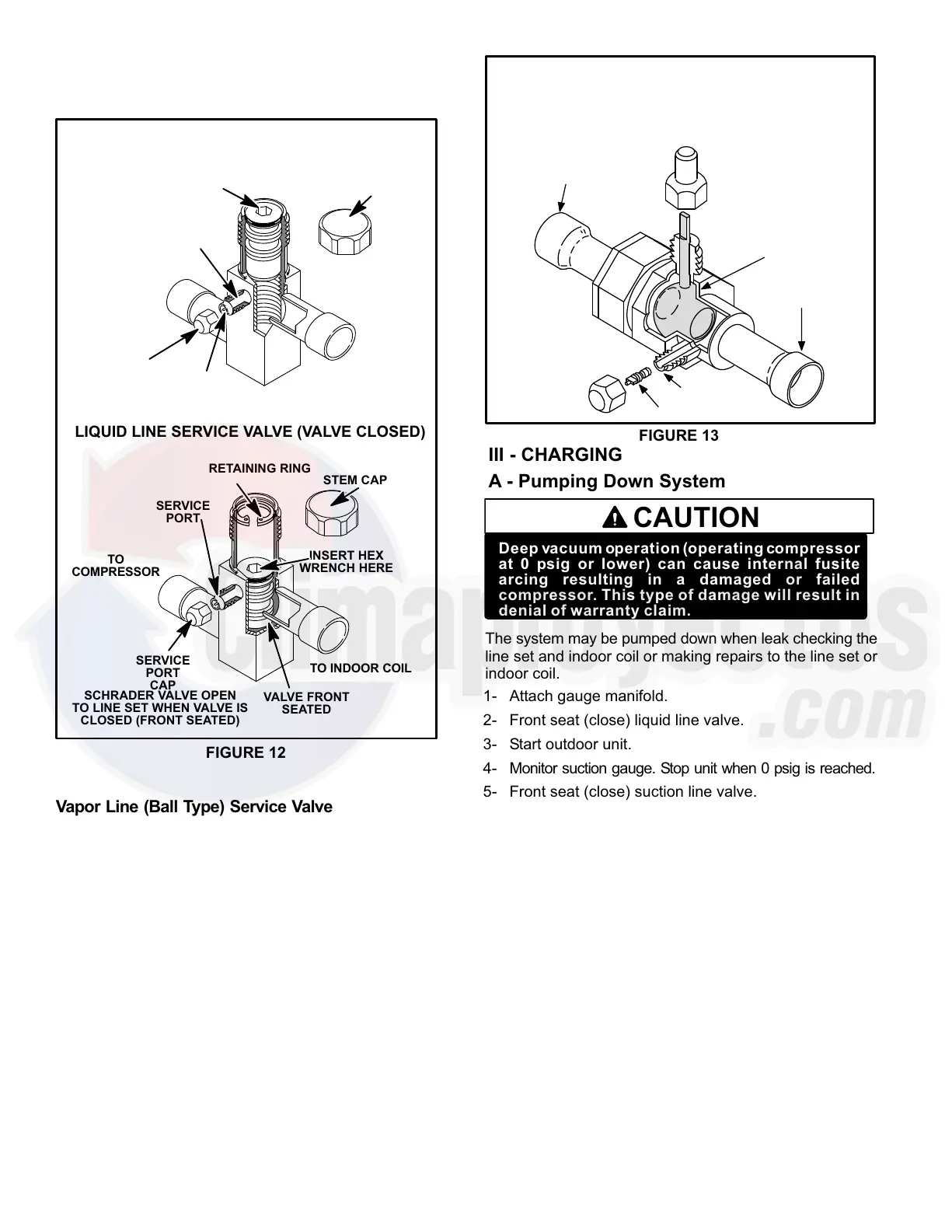

FIGURE 12

LIQUID LINE SERVICE VALVE (VALVE OPEN)

SCHRADER

VALVE

SERVICE

PORT

SERVICE

PORT

CAP

INSERT HEX

WRENCH HERE

TO INDOOR COIL

TO COMPRESSOR

STEM CAP

SCHRADER VALVE OPEN

TO LINE SET WHEN VALVE IS

CLOSED (FRONT SEATED)

SERVICE

PORT

SERVICE

PORT

CAP

RETAINING RING

STEM CAP

TO

COMPRESSOR

INSERT HEX

WRENCH HERE

LIQUID LINE SERVICE VALVE (VALVE CLOSED)

VALVE FRONT

SEATED

TO INDOOR COIL

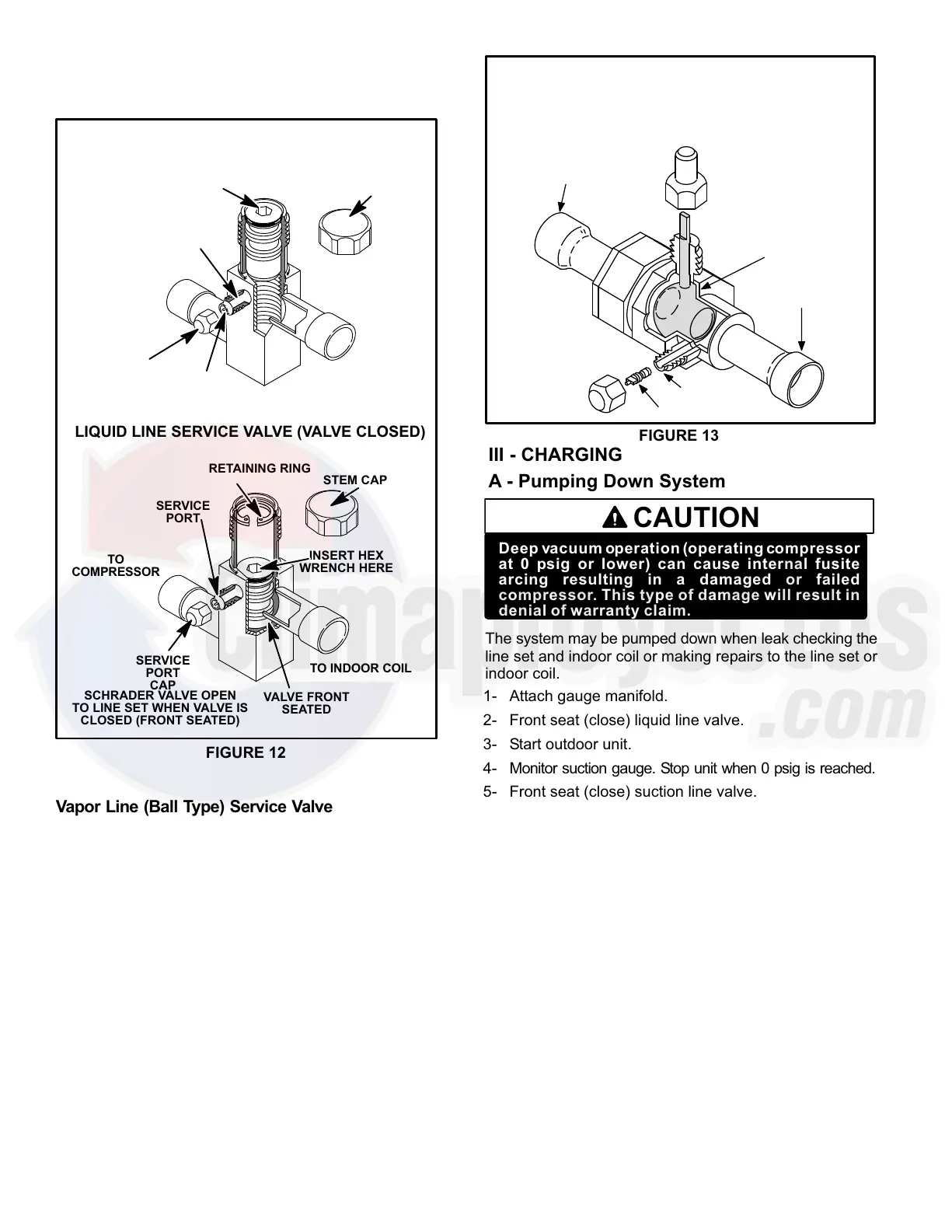

Vapor Line (Ball Type) Service Valve

A ball-type full service valve is used on 13HPX. Valves

are not re−buildable. If a valve has failed it must be replaced. A

ball valve is illustrated in figure 13.

The ball valve is equipped with a service port. A Schrader

valve is factory installed. A service port cap is supplied to pro-

tect the Schrader valve from contamination and assure a

leak free seal.

SUCTION LINE (BALL TYPE) SERVICE VALVE

(VALVE OPEN)

FIGURE 13

SCHRADER CORE

SERVICE PORT

SERVICE

PORT

CAP

STEM CAP

FROM INDOOR COIL

TO COMPRESSOR

STEM

USE ADJUSTABLE WRENCH

ROTATE STEM CLOCKWISE 90_ TO CLOSE

ROTATE STEM COUNTER-CLOCKWISE 90_ TO OPEN

BALL

(SHOWN OPEN)

III − CHARGING

A − Pumping Down System

CAUTION

Deep vacuum operation (operating compressor

at 0 psig or lower) can cause internal fusite

arcing resulting in a damaged or failed

compressor. This type of damage will result in

denial of warranty claim.

The system may be pumped down when leak checking the

line set and indoor coil or making repairs to the line set or

indoor coil.

1− Attach gauge manifold.

2− Front seat (close) liquid line valve.

3− Start outdoor unit.

4− Monitor suction gauge. Stop unit when 0 psig is reached.

5− Front seat (close) suction line valve.

B − Leak Testing (To Be Done

Before Evacuating)

1− Attach gauge manifold and connect a drum of dry nitro-

gen to center port of gauge manifold.

2− Open high pressure valve on gauge manifold and

pressurize line set and indoor coil to 150 psig (1034

kPa).

3− Check lines and connections for leaks.

Loading...

Loading...