Page 8

(open) at 25 + 5 psi. The switch automatically resets when

suction line pressure rises above 40 + 5 psi. Under certain

conditions the low pressure switch is ignored. See Pres-

sure Switch Circuit in the Defrost Control description.

G − Drier

A filter drier designed for all 13HPX model units is factory

installed in the liquid line. The filter drier is designed to re-

move moisture and foreign matter, which can lead to com-

pressor failure.

Moisture and / or Acid Check

Because POE oils absorb moisture, the dryness of the

system must be verified any time the refrigerant sys-

tem is exposed to open air. A compressor oil sample

must be taken to determine if excessive moisture has been

introduced to the oil. Table 2 lists kits available from Lennox

to check POE oils.

If oil sample taken from a system that has been exposed to

open air does not test in the dry color range, the filter drier

MUST be replace.

IMPORTANT

Replacement filter drier MUST be approved for

R−410A refrigerant and POE application.

Foreign Matter Check

It is recommended that a liquid line filter drier be replaced

when the pressure drop across the filter drier is greater

than 4 psig. To safeguard against moisture entering the

system follow the steps in section III − sub section

C − "Evacuating the System" when replacing the drier.

H − Crankcase Heater HR1 & Thermostat

S40 (options)

Crankcase heater HR1 is an option for all size units, while

thermostat S40 is an option for 5 ton units only. HR1 is a 40

watt heater that prevents liquid from accumulating in the

compressor. In the 13HPX−060 (5 ton unit) HR1 is con-

trolled by thermostat S40 located in the liquid line. When

liquid line temperature drops below 50° F, S40 closes ener-

gizing HR1. S40 will open once liquid line temperature

reaches 70°, de−energizing HR1.

TABLE 2

KIT CONTENTS

TUBE SHELF

LIFE

10N46 − Refrig-

erant Analysis

Checkmate−RT700

10N45 − Acid

Test Tubes

Checkmate−RT750A (three

pack)

2 − 3 years @

room tempera-

ture. 3+ years re-

frigerated

10N44 − Mois-

ture Test Tubes

Checkmate − RT751 Tubes

(three pack)

6 − 12 months @

room tempera-

ture. 2 years re-

frigerated

74N40 − Easy

Oil Test Tubes

Checkmate − RT752C Tubes

(three pack)

2 − 3 years @

room tempera-

ture. 3+ years re-

frigerated

74N39 − Acid

Test Kit

Sporian One Shot − TA−1

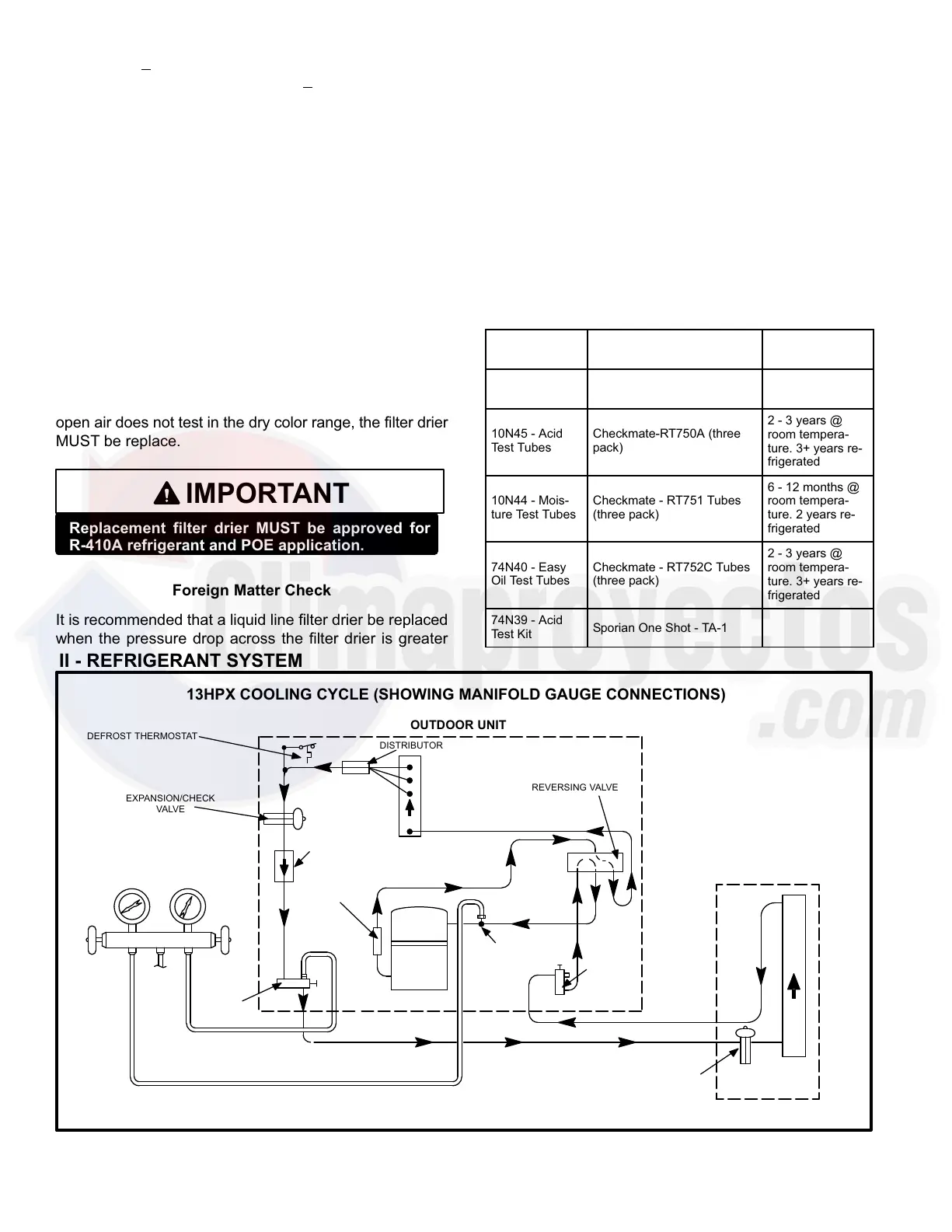

II − REFRIGERANT SYSTEM

FIGURE 10

13HPX COOLING CYCLE (SHOWING MANIFOLD GAUGE CONNECTIONS)

OUTDOOR

COIL

DEFROST THERMOSTAT

EXPANSION/CHECK

VALVE

BIFLOW

FILTER / DRIER

TO

R−410A

DRUM

LOW

PRESSURE

HIGH

PRESSURE

COMPRESSOR

REVERSING VALVE

VAPOR

LINE

VALVE

MUFFLER

NOTE − ARROWS INDICATE DIRECTION OF REFRIGERANT FLOW

SERVICE

PORT

SUCTION

EXPANSION/CHECK

VALVE

INDOOR UNIT

OUTDOOR UNIT

LIQUID LINE

SERVICE

PORT

GAUGE MANIFOLD

DISTRIBUTOR

INDOOR

COIL

Loading...

Loading...