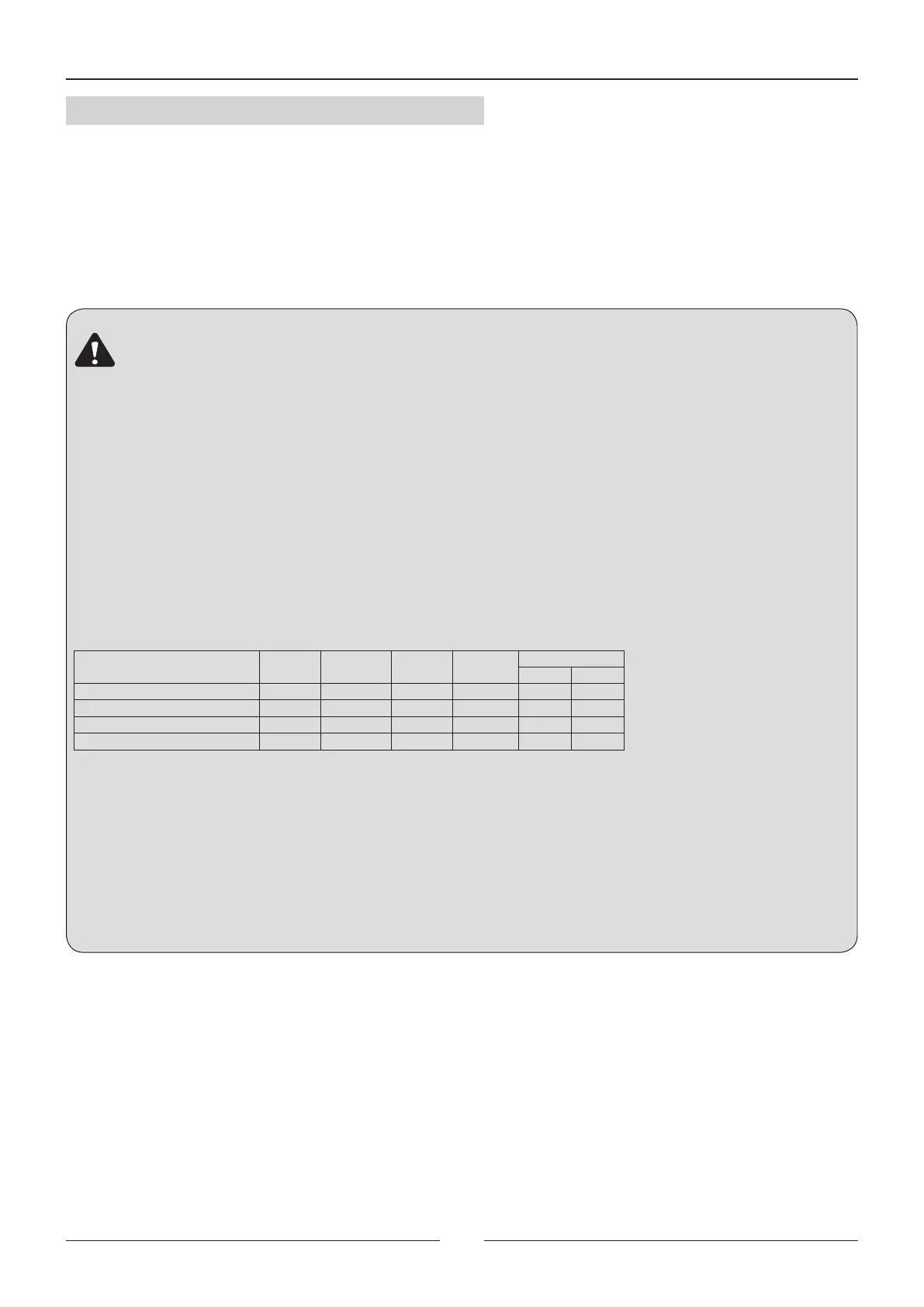

10% 1,05 1,02 0,997 0,995 0,994

20% 1,10 1,05 0,996 0,985 0,993

30% 1,15 1,08 0,995 0,975 0,99

35% 1,18 1,10 0,994 0,965 0,987

31

Example: 10 % glycol in EAC 0251SMHN

Minimum ow: 3,16 m

3

/h x 1,02

Pressure drop: 175 x 1,05

System capacity x 0,995

Power input x 0,997

MINIMUM AMBIENT TEMPERATURE

OR WATER OUTLET TEMPERATURE

ETHYLENE

GLYCOL %

PRESSURE

DROP

WATER

FLOW

POWER

INPUT

CAPACITIES

COOL HEAT

FROM +5ºC TO 0ºC

FROM 0ºC TO -5ºC

FROM -5ºC TO -5ºC

FROM -10ºC TO -15ºC

2.7.- UNIT INSTALLATION

11.- For cooling or heat pump units the hydraulic system must contain the following components pump, buffer tank, expansion

device, safety valve, water lter, ow switch.

12.- To obtain the total water system pressure drop add the unit pressure drop + water pipework + ttings and terminal unit

pressure drops the water pump can be selected to provide the correct water ow across the heat exchanger.

13.- A water balancing valve is advised to ensure correct water ow.

IMPORTANT

If the outside temperature in the area where the EcoLeanTM unit is to be installed is likely to drop below 5°C, it is

very important to take the following precautions to avoid that water in the circuit freezing, that may produce damage

to the components.

- If unit has to work under low outside temperatures:

* Do not disconnect power supply in order that water pump starts when detects water temperatures below +5 ºC

(only Hydraulic and Hydronic models).

* If the outside temperature where the system is to be installed or the water outlet temperature is likely to drop below

5ºC, it is very important to use glycol anti-freeze.

The amount of anti-freeze required will vary depending on the minimum ambient temperature or the water outlet

temperature.

When the percentage of glycol increases the standard pump ow decreases, the pressure drop increases and the

cooling and thermal capacities drop. As a result the minimum ow must be multiplied by the coefcient shown in

the table:

Also is advisable to use the option “evaporator anti freeze protection”

Failure to follow this advice, may result in damage to the installation.

Optionally, an immersion heater can be supplied complete with safety thermostat and pressure switch tted in the

buffer tank of the cooling only chiller. A similar option is available for heat pump versions with the added advantage of a

supplementary heating source (Hydronic version units).

2.- INSTALLATION

Loading...

Loading...