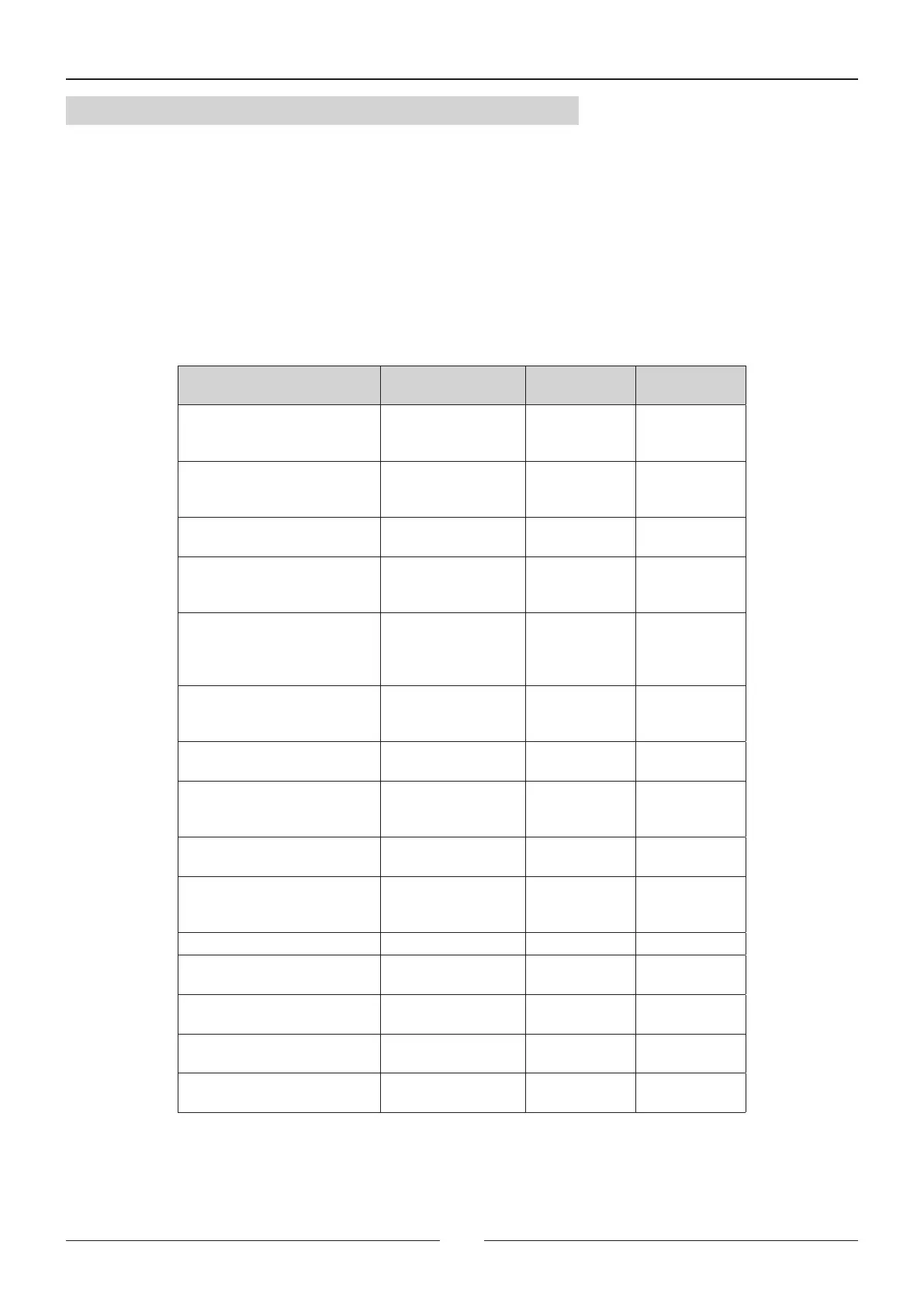

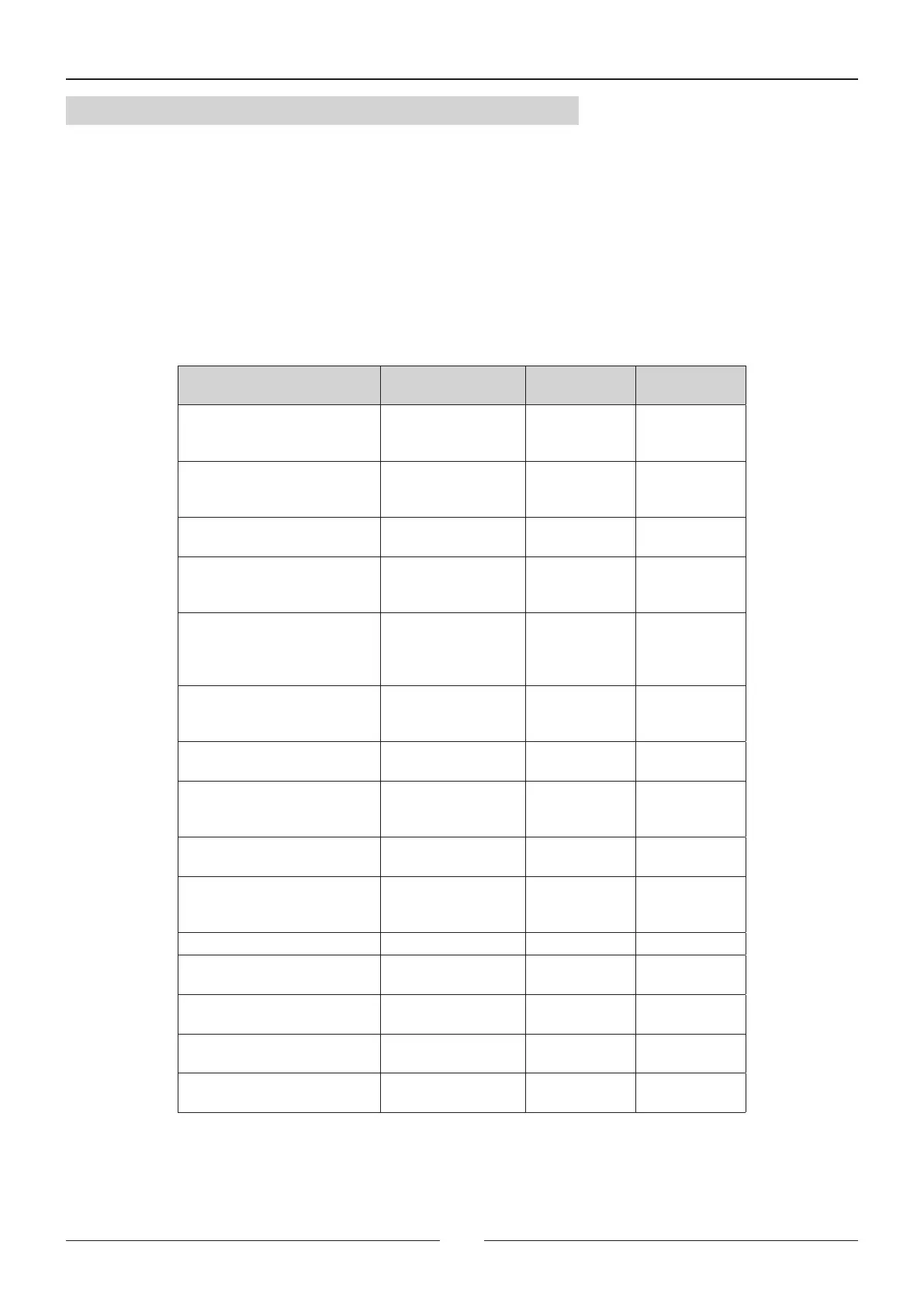

<70

70-300

>300

+

+

+

0

+

0

<70

70-300

>300

+

+

0

+

-

-

>1.0

<1.0

+

+

+

-

<10µS/cm

10-500µS/cm

>500µS/cm

+

+

+

0

+

0

<6.0

6.0-7.5

7.5-9.0

>9.0

0

0/+

+

+

0

0

+

0

<2

2-20

>20

+

+

+

+

0

-

<50

>50

+

0

+

0

<1

1-5

>5

+

+

0/+

+

0

-

<0.05

>0.05

+

+

+

-

<5

5-20

>20

+

+

+

+

0

-

4.0-8.5 + +

<100

>100

+

+

+

0

<0.2

>0.2

+

+

+

0

<0.2

>0.2

+

+

+

0

<0.1

>0.1

+

+

+

0

35

3.3.- CORROSION RESISTANCE OF COPPER AND STAINLESS STEEL OF PLATES EXCHANGER

(WATER EXCHANGER)

GUIDE TO MEASURE A ANALYSIS OF THE WATER IN THE CIRCUIT.

The resistance guide below is an attempt of give a picture of the corrosion resistance of the stainless steel of the type AISI

316 and pure copper in the water, to a number of important chemical factors. The actual corrosion is however a very complex

process inuenced by many factors in combination. This table is therefore a considerable simplication and should not be

overvalued.

Explanations:

+ Good resistance under normal conditions

0 Corrosion problems can occur especially when the factors are valued as 0

- Use is not recommended

WATER CONTAINING

CONCENTRATION

mg/l ó ppm

AISI 316 COPPER

Alcalinity (HCNO

3

)

Sulfate (SO

4

2-

)

HCO

3

/ SO

4

2-

Electrical conductivity

pH

Amonium (NH

3

)

Chloroides (Cl

-

)

Free chlorine (Cl

2

)

Hydrogen sulde (H

2

S)

Free( aggressive) Carbon

Dioxide (CO

2

)

Total hardness (ºdH)

Nitrate (NO

3

)

Iron (Fe)

Aluminium (Al)

Manganese (Mn)

3.- COMMISSIONING AND OPERATION

Loading...

Loading...