Page 23

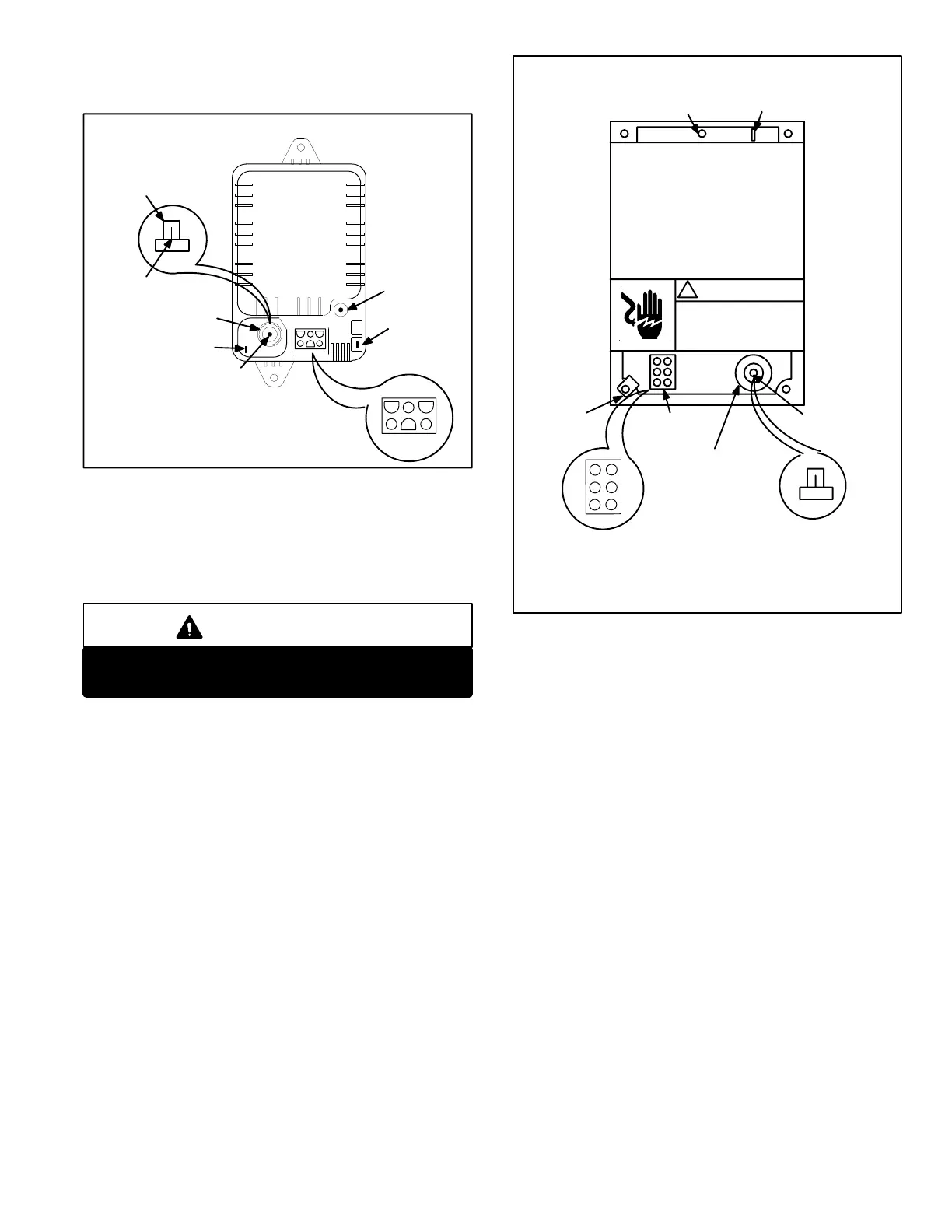

Spark wire connection is made to a barbed nail type con

nector on the control. Sensor wire connection is made to a

3/16" quick connect terminal opposite the barbed nail.

GREEN

LED

123

456

NEUTRAL

SENSE

TERMINAL

BARBED NAIL

CONNECTOR

TRANSFORMER

GC3 IGNITION CONTROL

1 24 VAC FROM TSTAT W"

2 COMMON

3 24 VAC TO GAS VALVE

4 24 VAC INPUT FROM TRANSFORMER T1

5 120 VAC TO PURGE BLOWER

6 120 VAC INPUT

TO REMOVE WIRE:

GRASP WIRE WITH

FINGERS AND PULL

STRAIGHT OUT

BARBED NAIL

CONNECTOR

J72

CONNECTOR

FIGURE 19

Three models of the GC3 were made, early model

(72H68−white cover) and later models (97H02−white cover

and 52J18−green cover). The early model GC3 stops

spark as soon as a suitable flame is sensed, while the later

model energizes the spark for a full eight seconds.

IMPORTANT

A ceramic resistor spark plug must be used with

Lennox ignition controls.

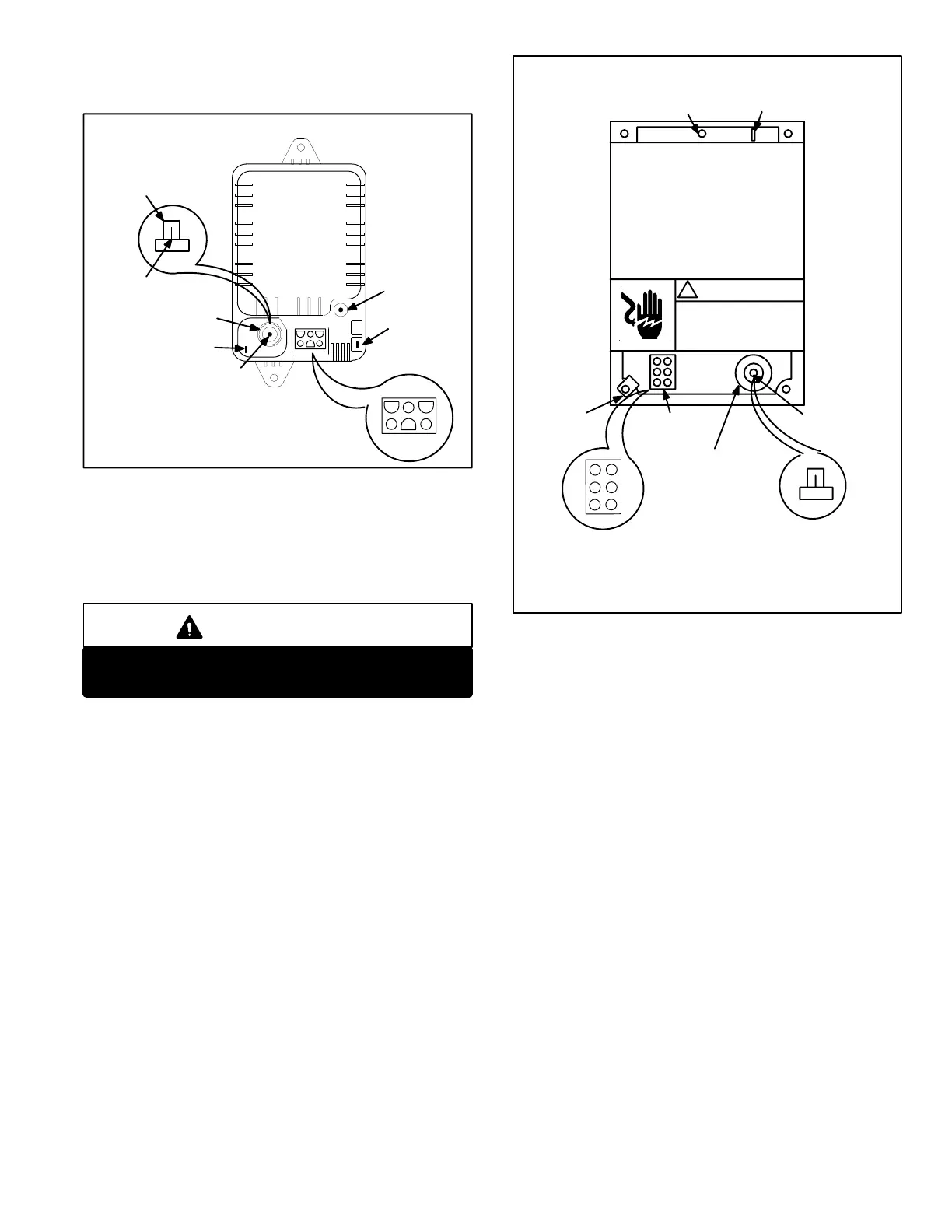

3 − Johnson G891 Ignition Control (Figure 20)

The Johnson G891 ignition control (A3) has a blue plastic

cover, and is illustrated in figure 20. The unit wiring harness

(P72) plugs directly into the jack (J72) at the bottom of the

control. A diagnostic indicator light, a green LED, is located

on the top center of the control, near the sense terminal.

Spark wire connection is made to a barbed nail type con

nector on the control. Sensor wire connection is made to a

3/16" quick connect terminal opposite the barbed nail.

Like the later GC3 controls the G891 energizes the spark

for a full eight seconds.

GREEN

LED

1

2

3

4

5

6

NEUTRAL

SENSE

TERMINAL

BARBED

NAIL

CONNECTOR

TRANSFORMER

G891 IGNITION CONTROL

BARBED

NAIL

CONNECTOR

J72

CONNECTOR

FIGURE 20

!

1 24 VAC FROM TSTAT W"

2 COMMON

3 24 VAC TO GAS VALVE

4 24 VAC INPUT FROM TRANSFORMER T1

5 120 VAC TO PURGE BLOWER

6 120 VAC INPUT

4 − Ignition Control Functions For GC1, GC3,

and G891 (Figures 21 and 22)

The ignition control (A3) provides four main functions: pre

purge, ignition, flame sensing and postpurge. The ignition at

tempt sequence of the control provides five trials for ignition

before lock out. See figure 21 for normal ignition sequence

with nominal timings for simplicity.

Proper gas/air mixture is required for ignition on the first at

tempt. If there is slight deviation, within tolerance of the unit, a

second or third trial may be necessary for ignition.

The control will lock out the system if ignition is not obtained

within five trials. Reset after lockout requires only breaking and

remaking the thermostat demand. Watchguard will automati

cally reattempt ignition after one hour if there is still a thermo

stat heating demand. See figure 22 for the ignition attempt se

quence for retrials (nominal timings given for simplicity). Loss

of combustion during a heating cycle is sensed through ab

sence of flame signal causing the control to deenergize the

gas valve and repeat the ignition sequence if a thermostat

heating demand is present.

Ignition control timings (timing specific) are given in fig

ure 22.

Loading...

Loading...