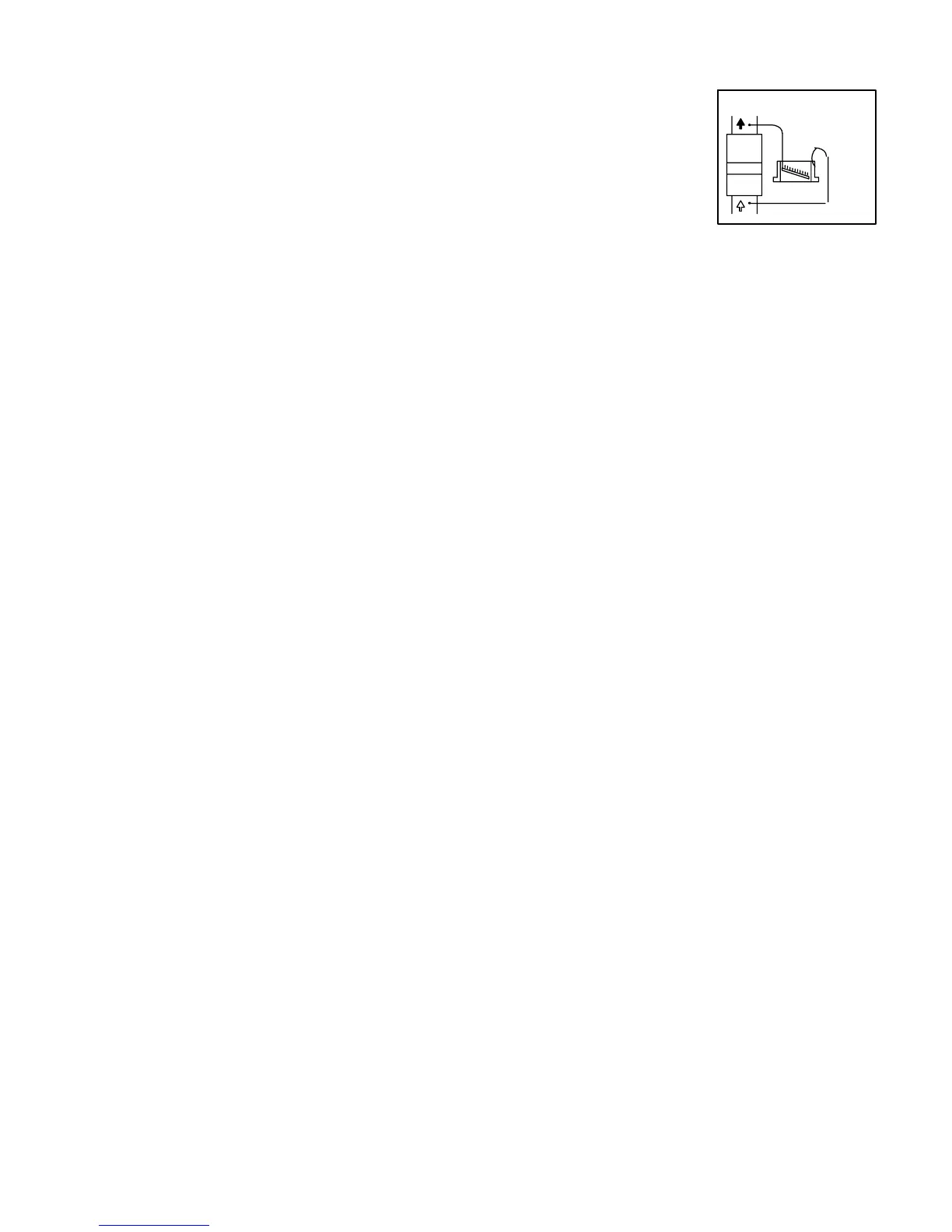

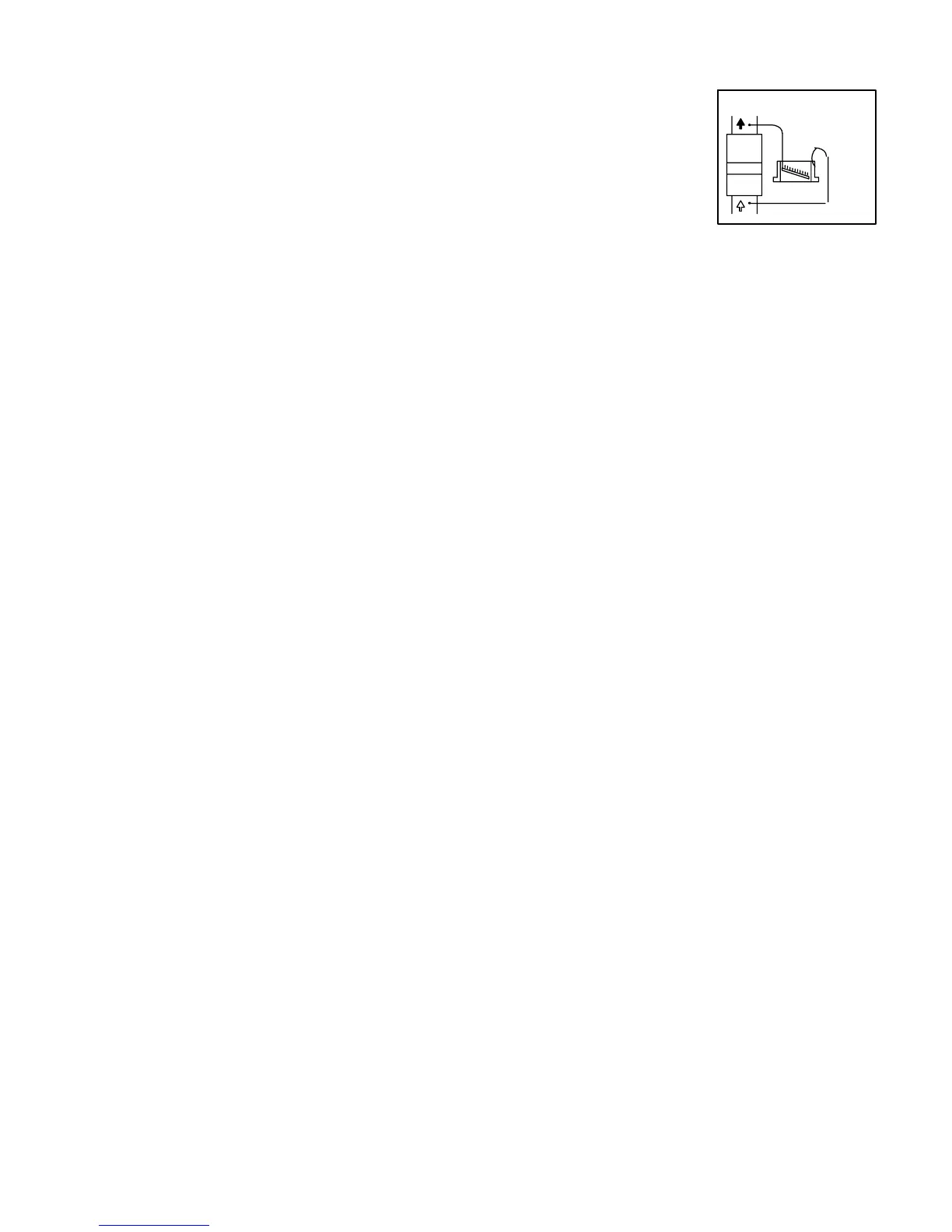

FIGURE 46

STATIC PRESSURE

TEST

G51MP UNIT

Page 38

V−TYPICAL OPERATING CHARACTERISTICS

A−Blower Operation and Adjustment

NOTE− The following is a generalized procedure and

does not apply to all thermostat controls.

1 − Blower operation is dependent on thermostat control

system.

2 − Generally, blower operation is set at thermostat subbase

fan switch. With fan switch in ON position, blower oper-

ates continuously. With fan switch in AUTO position,

blower cycles with demand or runs continuously while

heating or cooling circuit cycles.

3 − In all cases, blower and entire unit will be off when the

system switch is in OFF position.

B−Temperature Rise

Temperature rise for G51MP units depends on unit input,

blower speed, blower horsepower, filter resistance and

installed duct system resistance. The blower speed must be

set for unit operation within the range of AIR TEMP. RISE

°F" listed on the unit rating plate.

To Measure Temperature Rise:

1− Place plenum thermometers in the supply and return air

plenums. Locate supply air thermometer in the first hori-

zontal run of the plenum where it will not pick up radiant

heat from the heat exchanger.

2 − Set thermostat to highest setting.

3 − After plenum thermometers have reached their highest

and steadiest readings, subtract the two readings. The

difference should be in the range listed on the unit rating

plate. If the temperature is too low, decrease blower

speed. If temperature is too high, first check the firing

rate. Provided the firing rate is acceptable, increase

blower speed to reduce temperature. To change blower

speed taps see the Blower Speed Taps section in this

manual.

C−External Static Pressure

1 − Measure tap locations as shown in figure 46.

2 − Punch a 1/4" diameter hole in

supply and return air ple-

nums. Insert manometer

hose flush with inside edge of

hole or insulation. Seal

around the hose with perma-

gum. Connect the zero end of

the manometer to the dis-

charge (supply) side of the system. On ducted systems,

connect the other end of manometer to the return duct

as above. For systems with non−ducted returns, leave

the other end of the manometer open to the atmo-

sphere.

3 − With only the blower motor running and the evaporator

coil dry, observe the manometer reading. Adjust blower

motor speed to deliver the air desired according to the

job requirements.

4 − Static pressure must not exceed 0.5" W.C.

5 − Seal around the hole when the check is complete.

D−Blower Speed Taps

(G51MP−2 & G51MP−090−3 and later units)

Blower speed tap changes are made on the SureLight

®

con-

trol. See figure 8. Unused taps must be secured on dummy

terminals "PARK" on the SureLight board. The heating tap is

connected to the "HEAT " terminal and the cooling tap is con-

nected to the "COOL" terminal. The continuous blower tap is

connected to the "FAN" terminal. To change existing heat tap,

turn off power then switch speed tap on HEAT" terminal with

tap connected to one of two PARK" terminals. See unit wir-

ing diagram for blower speed tap

E−Blower Speed Taps

(All G51MP −1 and G51MP−090−2 units)

Blower speed tap changes are made on the SureLight

®

con-

trol. See figure 6. Unused taps must be secured on dummy

terminals "PARK M1" and or "PARK M2" on the SureLight

board. The heating tap is connected to the "ACB HEAT " ter-

minal and the cooling tap is connected to the "ACB COOL"

terminal. The continuous blower tap is connected to the

"ACB LOW" terminal. To change existing heat tap, turn off

power then switch speed tap on ACB HEAT" terminal with

tap connected to PARK M1" or PARK M2". See unit wiring

diagram for blower speed tap

Loading...

Loading...