Page 44

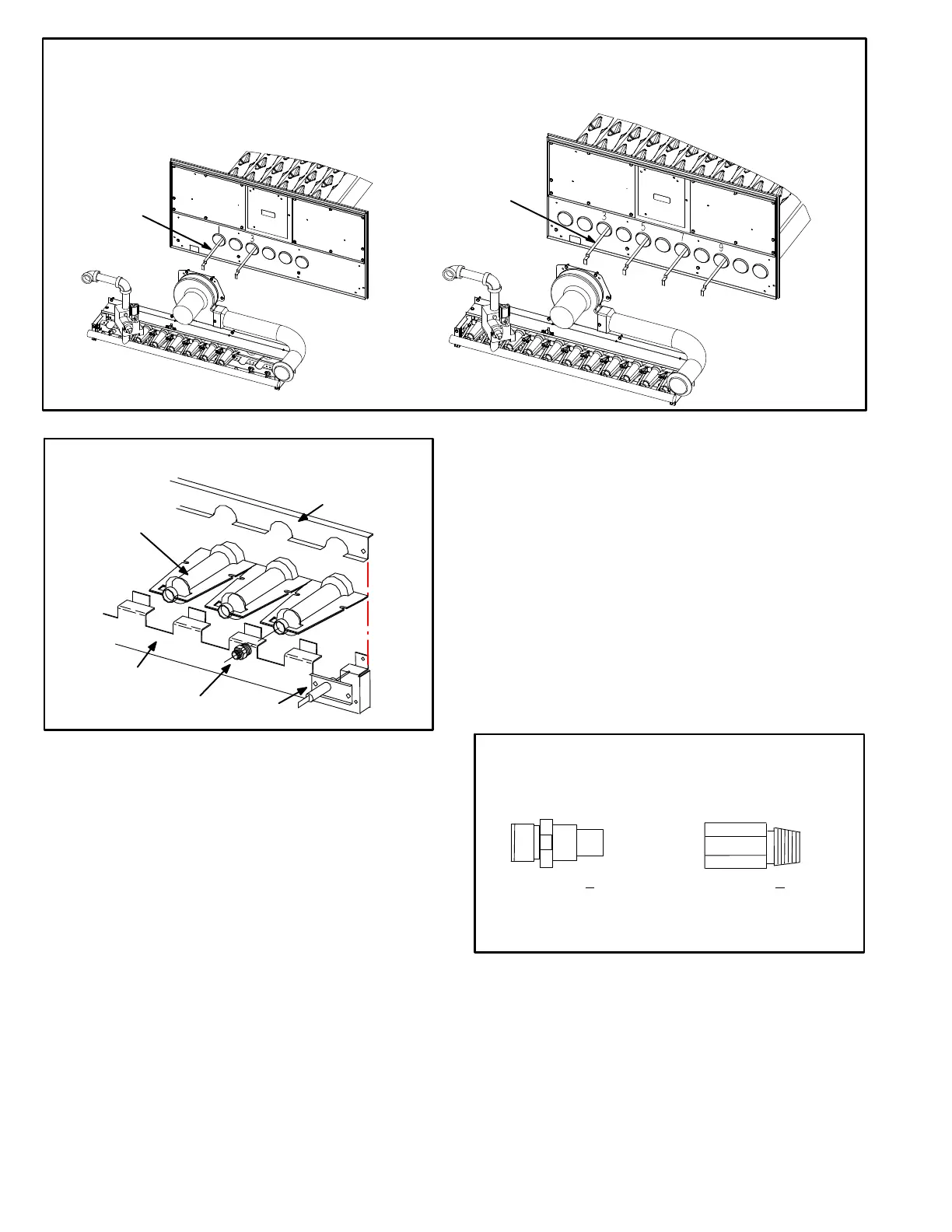

STANDARD HEAT (130,000BTUH)

INSERTS (2)

INSERTS (4)

HIGH HEAT (180,000BTUH)

Note - No inserts on

medium heat.

INSERT LOCATION - DIRECT DRIVE ONLY

FIGURE 27

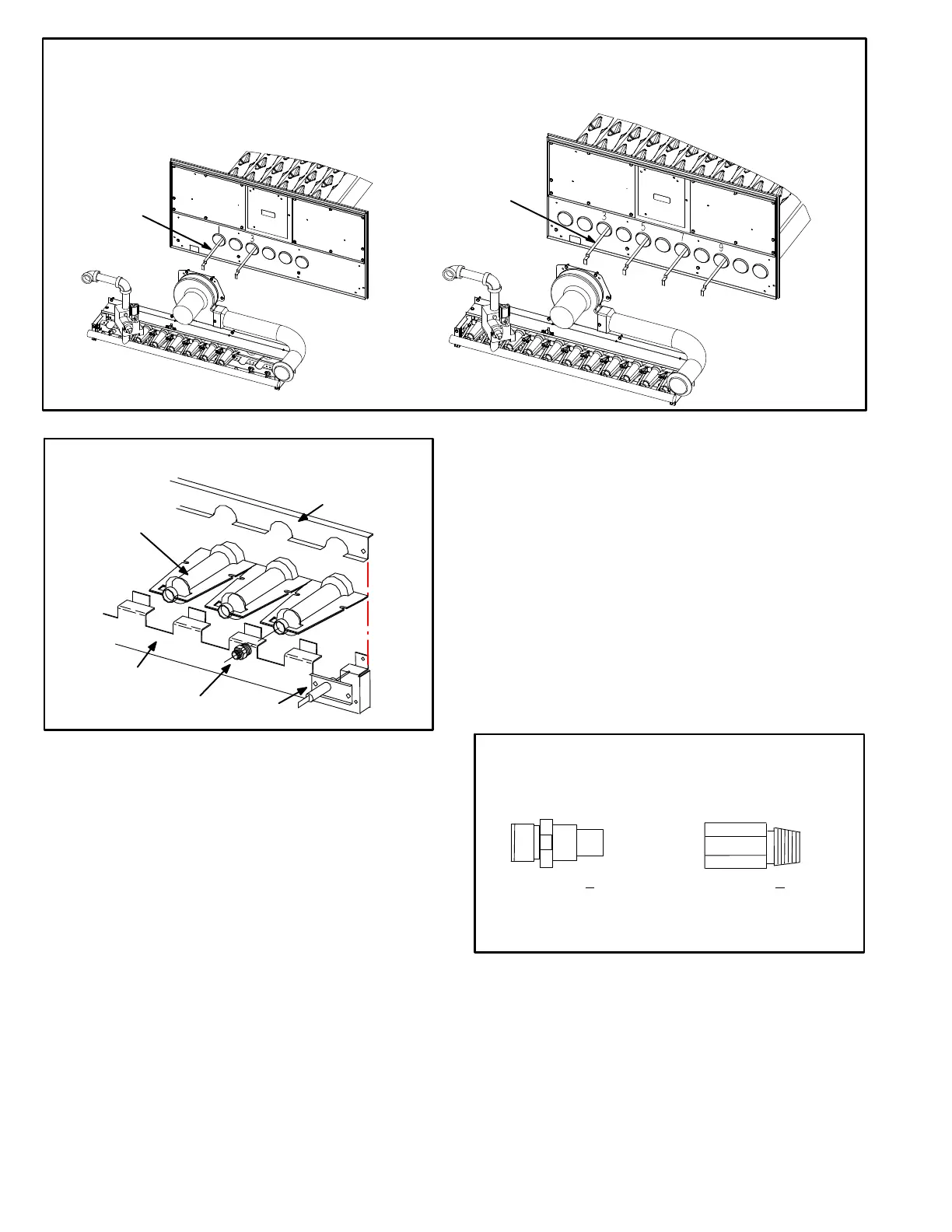

FIGURE 28

TYPICAL GAS BURNER ASSEMBLY

BURNERS

ORIFICE

SENSOR

BURNER

SUPPORT

BURNER

SUPPORT CAP

Orifice

Each burner uses an orifice (two types figure 29) which is

precisely matched to the burner input. Install only the

orifices with the same threads. The orifice is threaded

into the burner manifold. The burner is supported by the

orifice and will easily slide off for service.

NOTE-Do not use thread sealing compound on the

orifices. Using thread sealing compound may plug

the orifices.

Each orifice and burner are sized specifically to the unit.

Refer to ProductZone@www.davenet.com for correct siz

ing information.

5-Primary High Temperature Limits S10

S10 is the primary high temperature limit and is located on the

blower deck to the right of the blower housing.

Primary limit S10 is wired to the A55 Unit Controller which

energizes burner 1 control (A3). Its N.C. contacts open to

de-energize the ignition control when excessive tempera

ture is reached in the blower compartment. At the same

time, the N.O. contacts of S10 close energizing the blower

relay coil K3 through A55. If the limit trips the blower will be

energized. Limit settings are factory set and cannot be ad

justed. If limit must be replaced, the same type and set point

must be used.

ORIFICE WITH

PIPE THREADS

Tighten to 6.25 + .5 ft.lbs.

Do not over-tighten.

Tighten to 14 + .5 ft/lbs

Do not over-tighten.

ORIFICE WITH

STRAIGHT THREADS

FIGURE 29

Loading...

Loading...