80

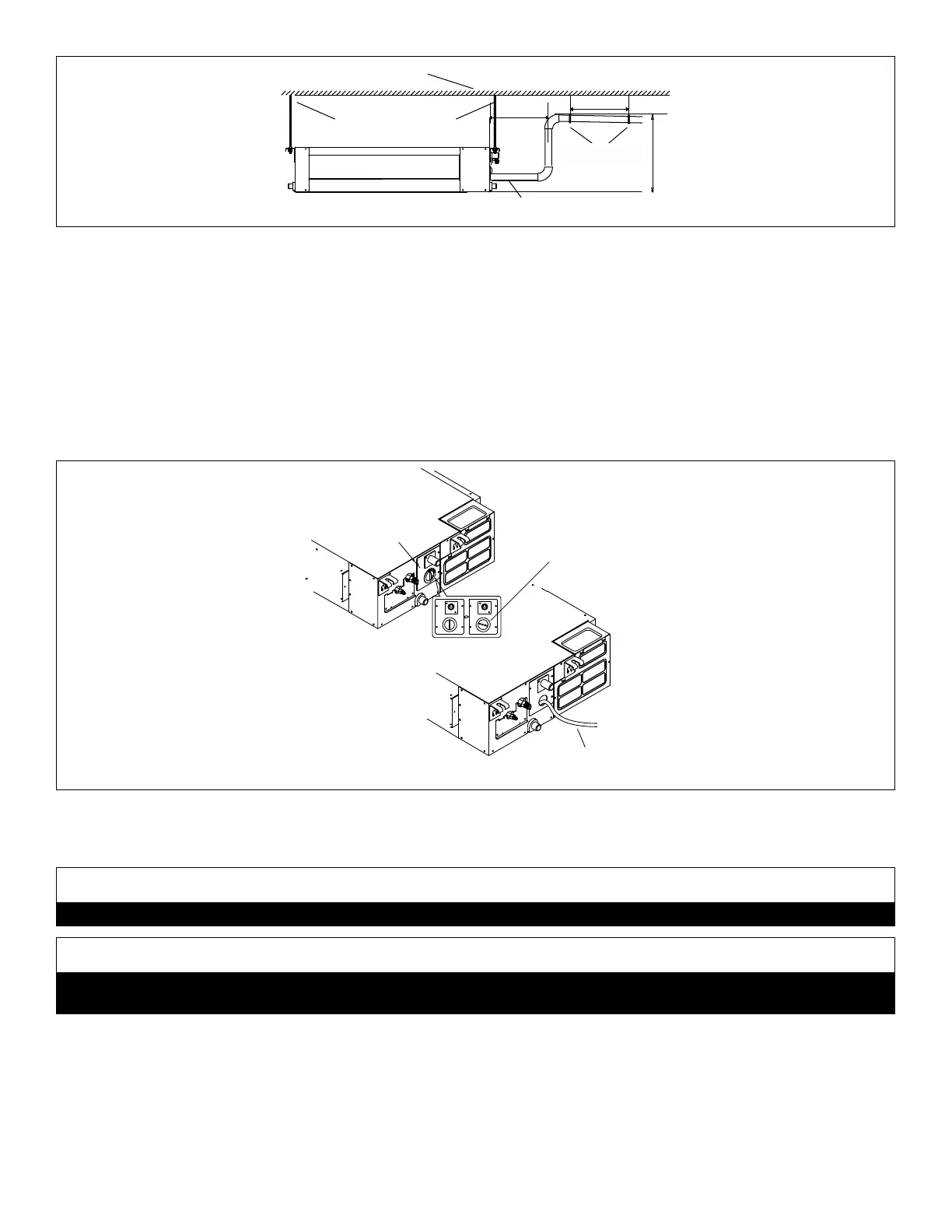

SUSPENSION RODS

DRAIN LINE

STRUCTURAL CEILING

8 in.

(203 mm)

Max. 28 in.

SUPPORT

STRAPS

3 ft. (1 m)

Figure 54. Condensate Drain with Pump

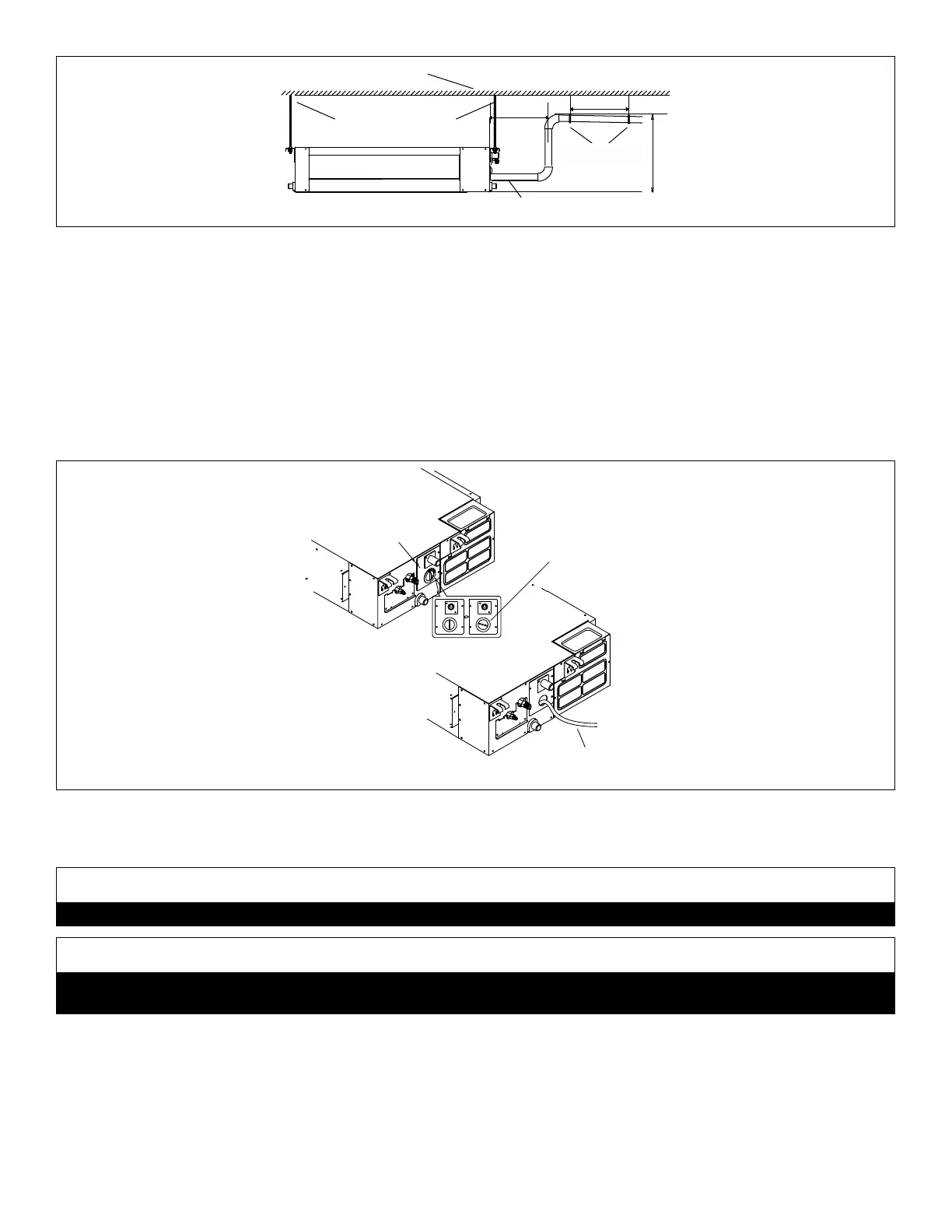

5. After system installation is complete, the condensate drain line must be checked for leaks and the condensate

pumps must be checked to ensure proper operation. This check is part of the start-up process which must be

done by the installing contractor. Turnthecondensatedrainpantestcoverlatchcounterclockwisetoopenthecover

andaccessthedrainpan. Seegurebelow.Funnelenoughwatertoengagethepumpintothe drainpanthrougha

exibletube.

6. Operatethesysteminthecoolingmode.Iftheinternalpumpisbeingused,ensurethatthepumpisoperatingandthe

waterinthepanisdrainingfreely.Iftheinternalpumpisnotbeingused,pourthewaterintothedrainpanandconrm

thatithasowedfreelyoutofthepanandoutofthedraintermination.Ifaleakisfound,shutdownpowertotheunitat

onceanddonotrestorepowertotheunituntiltheproblemhasbeenresolved.

7. Returnthetestcoverandturnthelatchclockwisetore-lockit.

DRAIN PAN

TEST COVER

FUNNEL WATER INTO

PAN THROUGH TUBE

FOR TEST

COVER LATCH

(Turn latch

counterclockwise

to unlock)

CL

OSE

D

O

PE

N

CLOS

E

D

O

PE

N

Figure 55. Condensate Drain Test

14.3.1.2 M22A, M33A and M33B

CAUTION

Makesurethatdrainpipingisproperlyroutedandinsulatedinordertopreventbothleaksandcondensation.

IMPORTANT

Drainshouldhaveaslopeofatleast¼inchperfootandshouldbeapprovedcorrosion-resistantpipe.Youmustconrm

operationofeverydrainandpumpinthesystemaspartofthecommissioningprocedure.

1. Useaeld-providedhoseclamptosecurethedrainlinestubonthesideofthecassettebasetoaeld-supplied1”(25

mm) drain line.

NOTE: Take care not to over-tighten the hose clamp as this may damage the drain line stub.

2. Seegurebelowforapplicationsusingtheunit’sinternalcondensatepumptoprovideliftintoadrain.Ensurethatthe

maindrainlineisproperlysloped(nolessthan1/4inchperfoot(18mmperm)).

3. Drainshouldbeasshortaspossibleandshouldnothaveanydroopsorkinksthatwouldrestrictcondensateowand

shallbeapprovedresistantpipe.

Loading...

Loading...