17

Securing the Outdoor Unit

Slab or Roof Mounting

Install the unit a minimum of 4 inches (102 mm) above the

roof or ground surface to avoid ice build-up around the

unit. Place the unit above a load bearing wall or area of

the roof that can adequately support the unit. Consult local

codes for rooftop applications.

CAUTION

Roof Damage!

This system contains both refrigerant and oil. Some

rubber roong material may absorb oil. This will cause

the rubber to swell when it comes into contact with oil.

The rubber will then bubble and could cause leaks.

Protect the roof surface to avoid exposure to refrigerant

and oil during service and installation. Failure to follow

this notice could result in damage to roof surface.

Securing Outdoor Unit to Slab, Frame, or Rails

If the outdoor unit is installed on a eld-provided slab or

frame, use lag bolts or equivalent to secure the outdoor

unit to the slab or frame.

Four Field-provided Anchor Bolts

Figure 27. Securing Outdoor Unit to Slab

Four Field-Provided

Anchor Bolts

Figure 28. Securing Outdoor Unit to Rails

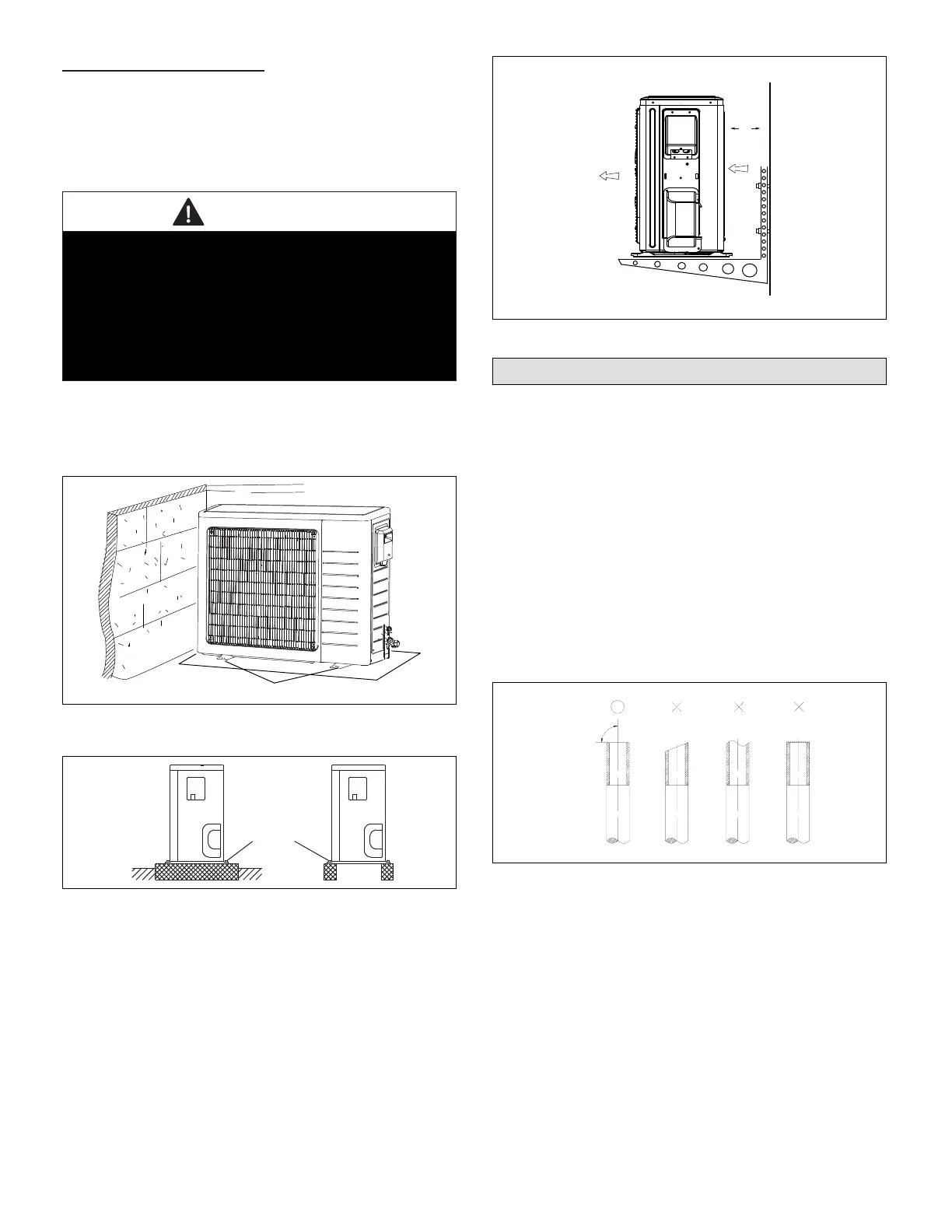

Securing Outdoor Unit to Hanging Brackets

If the outdoor unit is installed on eld-provided wall

mounting brackets, use lag bolts or equivalent to secure

the outdoor unit to the bracket. Minimum rear clearance

can be reduced to 6 inches (152 mm) when mounted on

brackets and with no obstructions on the other three sides.

Allow for condensate disposal when placing units above

one another.

Air Outlet

Air Inlet

6 in

152 mm

Figure 29. Securing Outdoor Unit to Brackets

Refrigerant Piping Connections

Line sets consists of two copper pipes connecting the

outdoor unit to the indoor unit. “Table 5. Refrigerant Piping

and Indoor Unit Connection Sizes” on page 18 lists

the connection sizes. The connections are made using

the provided brass are nuts at the end of the refrigerant

piping connections.

1. Choose the correct pipe sizes for your application

using “Table 5. Refrigerant Piping and Indoor Unit

Connection Sizes” on page 18.

2. Conrm that you are using the correct diameter piping.

3. Determine the necessary piping length required for the

application.

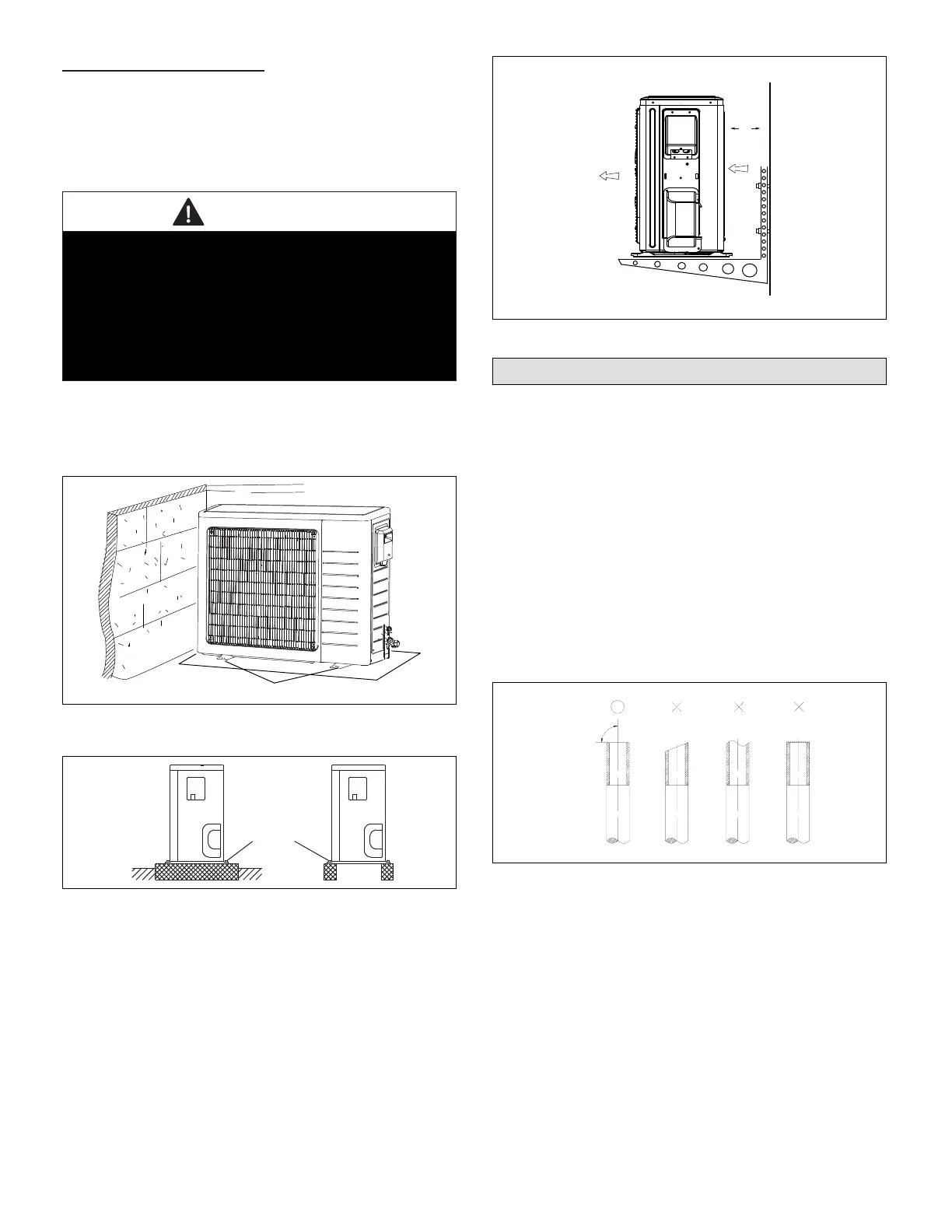

4. Cut the selected pipes with a pipe cutter. Make the cuts

at and smooth as illustrated in “Figure 30. Cutting

Piping”.

Figure 30. Cutting Piping

5. Insulate the copper piping.

6. Insert a are nut onto each pipe before aring.

7. Use “Table 4. Flaring Piping” on page 18 to properly

are the pipe.

Loading...

Loading...