19

Table 7. Refrigerant Line Set Requirements

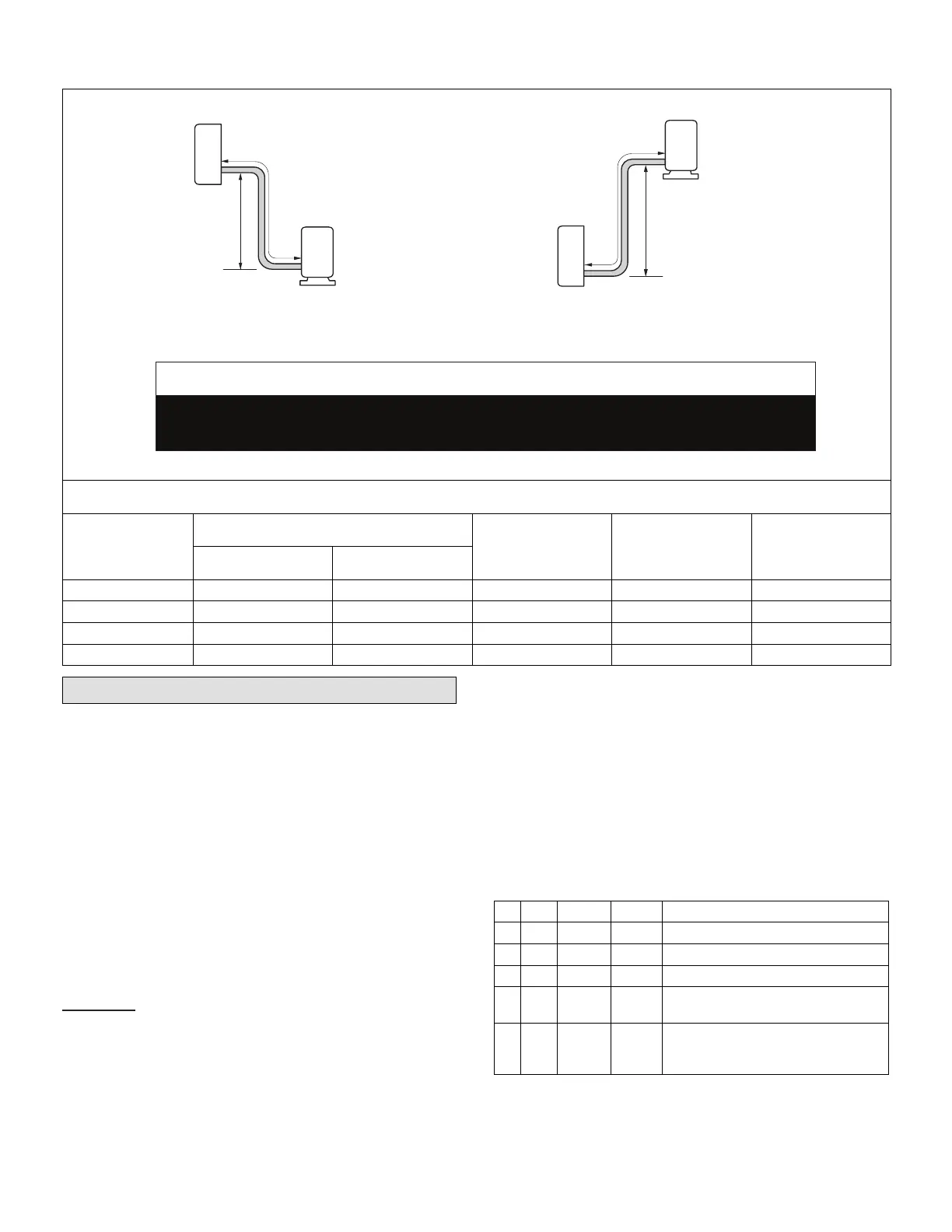

OUTDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

INDOOR UNIT

Maximum Line Set

Length

Maximum Line Set

Length

Maximum

Elevation -

Outdooor

Unit BELOW

Indoor Unit

Maximum

Elevation -

Outdooor

Unit ABOVE

Indoor Unit

Minimum Line Set

Length - 10 ft. (3m)

Minimum Line Set

Length - 10 ft. (3m)

Outside Unit BELOW Indoor Unit Outside Unit ABOVE Indoor Unit

Do not allow for excess length of line sets to be left rolled up as part of the

required distance, or in general. This will also cause additional performance issues.

IMPORTANT

Each system size has a line set length and vertical elevation parameters.

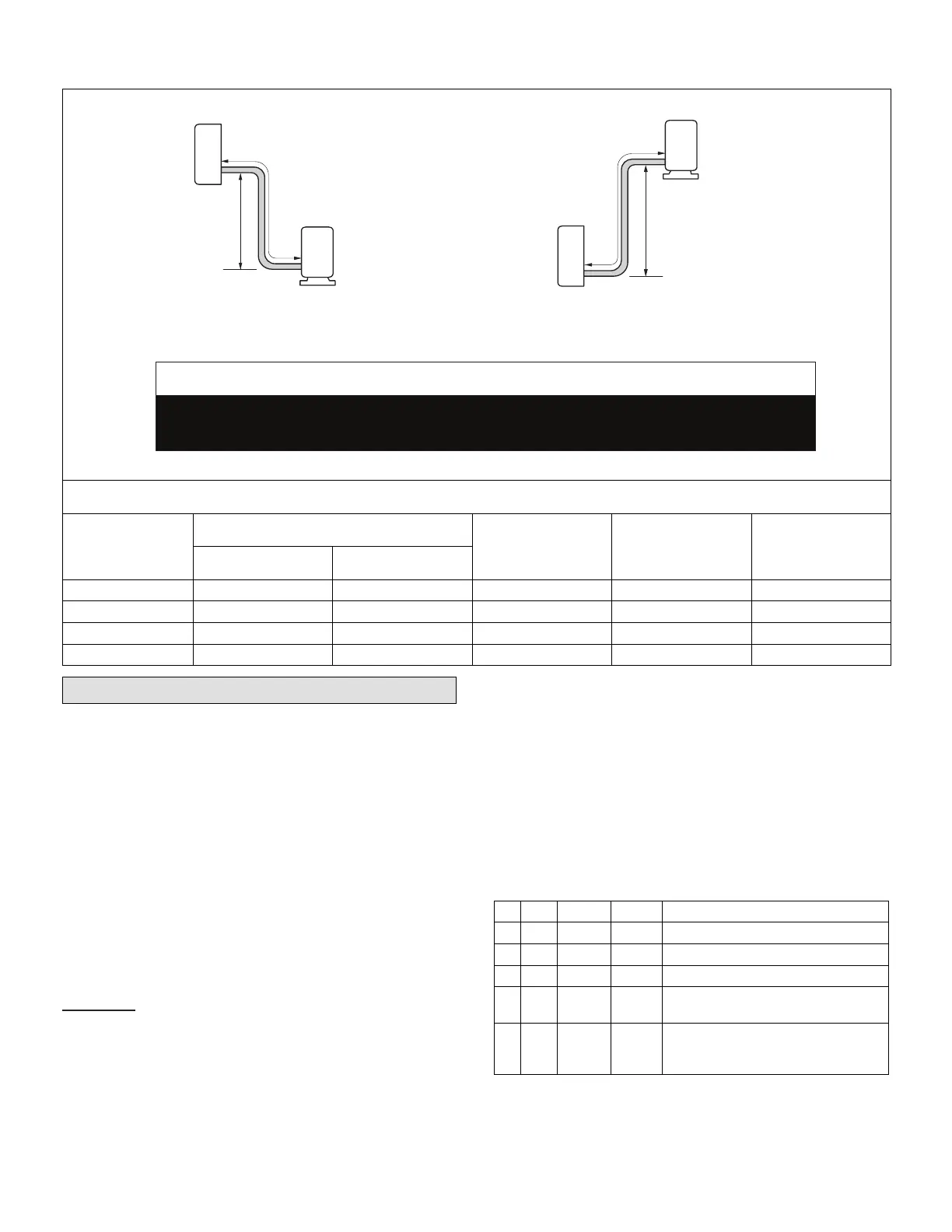

System Size (KBtu)

Line Set Diameters (in.)

Maximum Elevation

Outdoor Unit BELOW

Indoor Unit - Feet

(Meter)

Maximum Elevation

Outdoor Unit ABOVE

Indoor Unit - Feet

(Meter)

Maximum Line

Set Length - Feet

(Meters)

Liquid Gas

006, 009 1/4 3/8 40 (12) 40 (12) 82 (25)

012 1/4 1/2 40 (12) 40 (12) 82 (25)

018 1/4 1/2 66 (20) 66 (20) 98 (30)

024/030 3/8 5/8 82 (25) 82 (25) 164 (50)

Leak Test and Evacuation

Air and moisture remaining in the refrigerant system will

have undesirable effects as indicated below:

• Pressure in the system rises

• Operating current rises

• Cooling or heating efciency drops

• Moisture in the refrigerant circuit may freeze

• Water may lead to corrosion of parts in the refrigera-

tion system

The line set between the indoor and outdoor

units must be leak tested and evacuated to re-

move any non-condensables and moisture from

the system.

Leak Test

Use the following procedure to test for system

leaks:

1. Connect the manifold gauge set and dry nitrogen gas

cylinder to the suction and gas service ports.

2. Open valve on nitrogen cylinder.

3. Pressurize the system per the pressure test

specications in “Table 8. Pressure Test Specications”.

4. Check that the system pressure remains stable. If

there is any movement check system for leaks.

5. After the system is found to be free of leaks:

• Close valve on nitrogen cylinder

• Relieve the nitrogen pressure by: loosening the

charge hose connector at the nitrogen cylinder

• When the system pressure is reduced to normal,

disconnect the hose from the cylinder

Table 8. Pressure Test Specications

Bar Psig kPa Duration

1 3 44 303 Minimum of 10 minutes

2 15 220 1517 Minimum of 10 minutes

3 32 470 3241 Minimum of 10 minutes

4 45 650 4482

1 hour. Stress test to prove the

integrity of the complete installation.

5 32 470 3241

24 hours. Lower system pressure

test, after conrmation No. 4 was

successfully completed.

Loading...

Loading...