Lenze · Decentralised frequency inverter 8400 motec (CANopen option) · EDS84DMOTCAN EN 4.0 - 02/2019 41

Process data transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8 Process data transfer

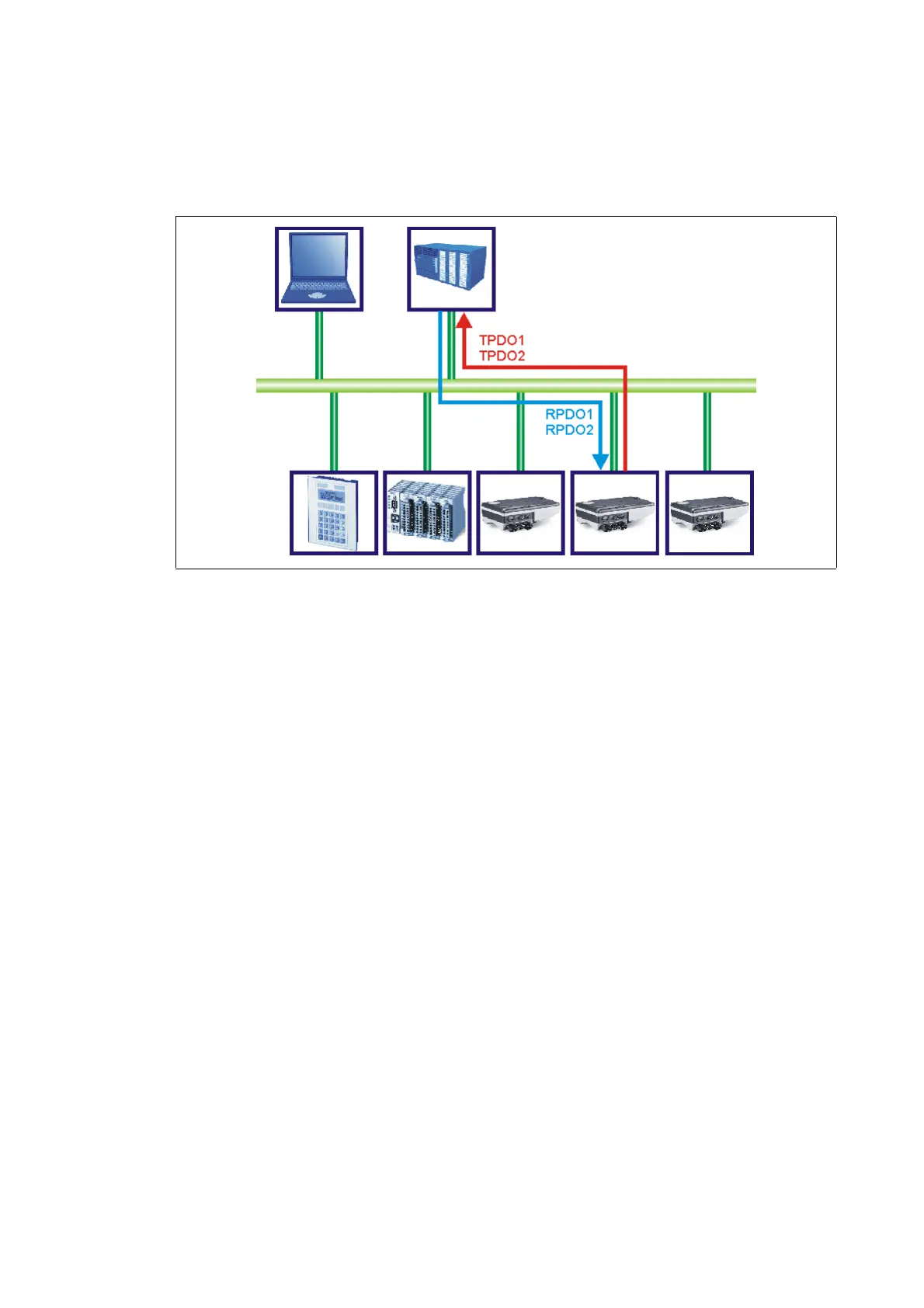

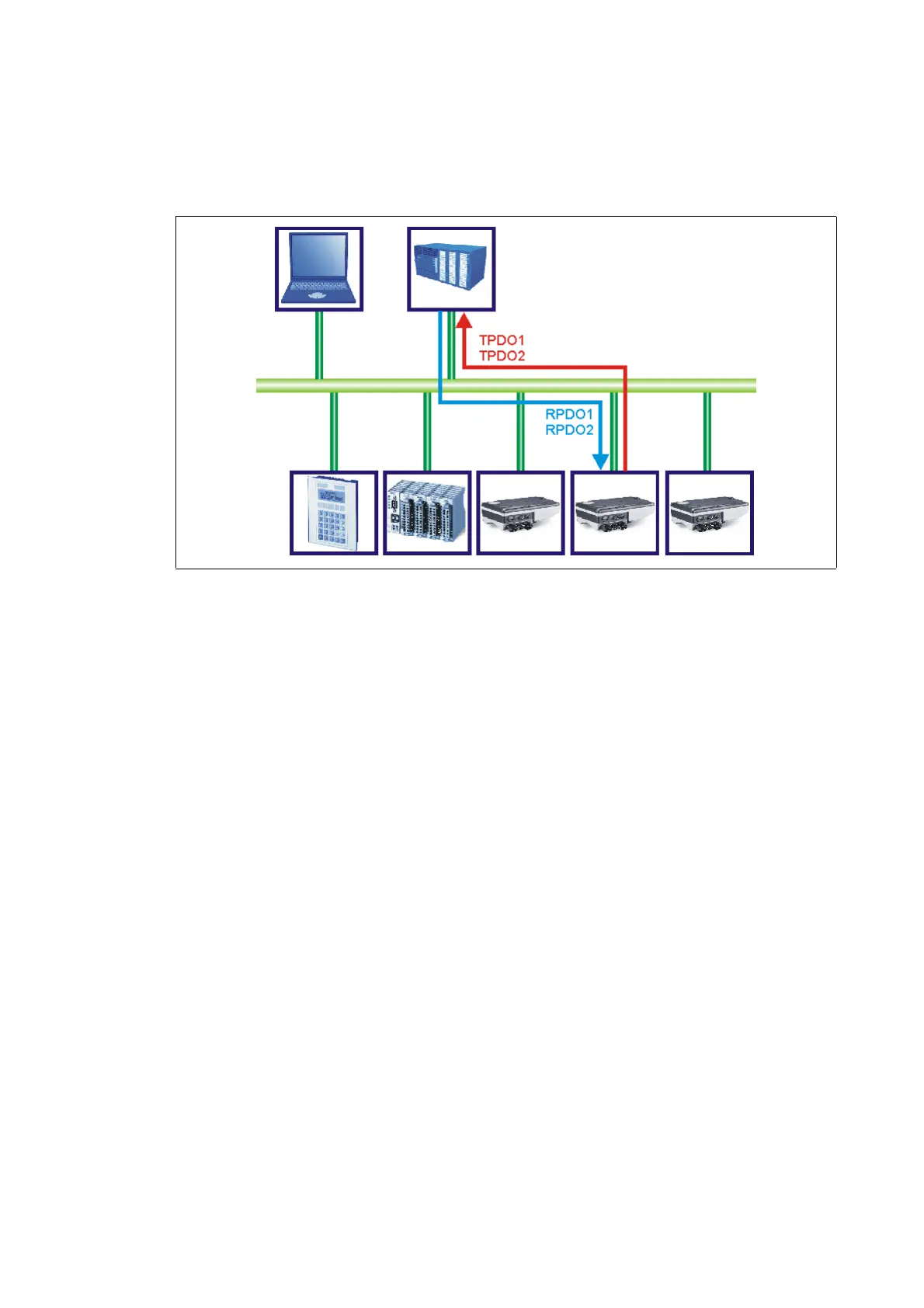

[8-1] PDO data transfer from / to the higher-level host (master)

The CANopen communication unit is provided with two separate process data channels (PDO1 and

PDO2) for transmitting process data. Each process data channel can transmit up to four words

(8 bytes) at a maximum.

The system bus (CANopen) transmits parameter data, configuration data, diagnostic data, alarm

messages and process data between the host (master) and the inverters (slaves) that are part of the

fieldbus. The data are transmitted via corresponding communication channels as a function of their

time-critical response.

• Process data are transmitted via the process data channel.

• The process data serve to control the inverter.

• The transmission of process data is time-critical.

• Process data are cyclically transferred between the master and the slaves participating in the

fieldbus (continuous exchange of current input and output data).

• The master can directly access the process data. In the PLC, for instance, the data are directly

assigned to the I/O area.

• Process data are not saved in the inverter.

• Process data are e.g. setpoints, actual values, control words, and status words.

Loading...

Loading...