Commissioning

5-5

BA9300SU EN 2.1

5.2.1 Operation with synchronous motors made by other manufacturers

Note!

If you use a Lenze synchronous motor with encoder feedback, you may skip this chapter.

Stop!

Please use single pole resolvers and single-turn or multi-turn sin/cos encoders only.

5.2.1.1 Rotor position adjustment

The rotor position must be adjusted, if:

• a motor other than from Lenze is used

• another encoder is mounted to the motor later (motor from another manufacturer but also

Lenze motors)

• a defective encoder has been replaced

The following steps are required:

1. Check the resolver poling

2. Optimise the current controller

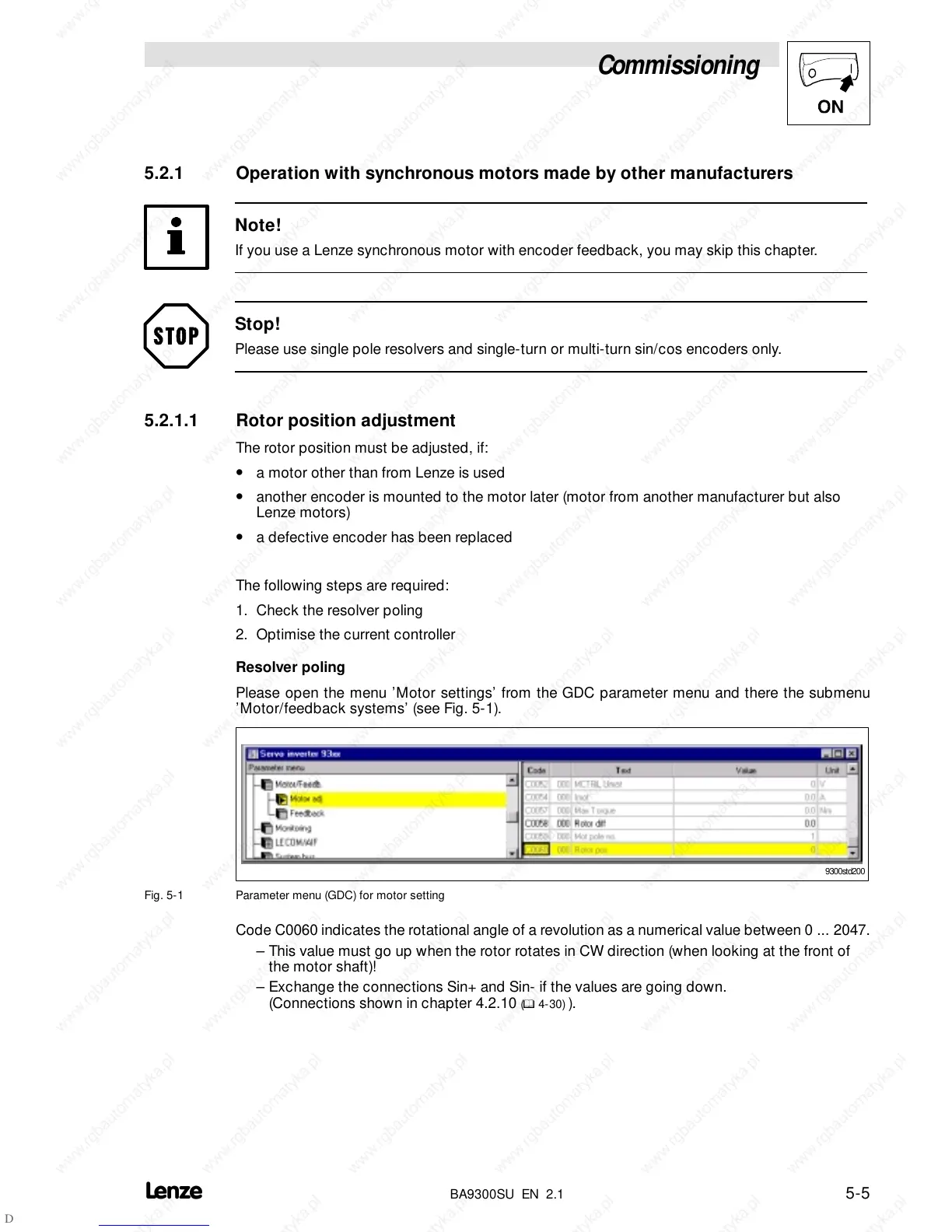

Resolver poling

Please open the menu ’Motor settings’ from the GDC parameter menu and there the submenu

’Motor/feedback systems’ (see Fig. 5-1).

9300std200

Fig. 5-1 Parameter menu (GDC) for motor setting

Code C0060 indicates the rotational angle of a revolution as a numerical value between 0 ... 2047.

– This value must go up when the rotor rotates in CW direction (when looking at the front of

the motor shaft)!

– Exchange the connections Sin+ and Sin- if the values are going down.

(Connections shown in chapter 4.2.10

(

^

4-30) ).

Loading...

Loading...