Mechanical installation

Preparation

Maximum permissible load at the motor adapter

4

26

Lenze ¯ MA 12.0012 ¯ 4.0

Gearbox with output flange

¯ Especially with regard to applications with an alternating load, Lenze

recommends...:

– the use of anaerobic adhesive between the gearbox flange and mounting area

in order to increase the friction fit;

– with steel or cast iron output flanges, the use of screws with a strength of 10.9

with correspondingly high tightening torques.

4.3.5 Maximum permissible load at the motor adapter

Stop!

¯ The loads generated by the motor mounted must be checked!

¯ The forces F

M

mentioned (see following tables) at the adapter must

not be exceeded!

For the effective force F

M

, static forces (e.g. weight) and dynamic forces (e.g.

acceleration forces, for example caused by vibrations or start−up processes) have to be

taken into consideration.

Furthermore the loading case of the force F

M

has to be taken into consideration:

Loading case k

loading

case

Static 1

Dynamic−pulsating 0.8

Dynamic−alternating 0.6

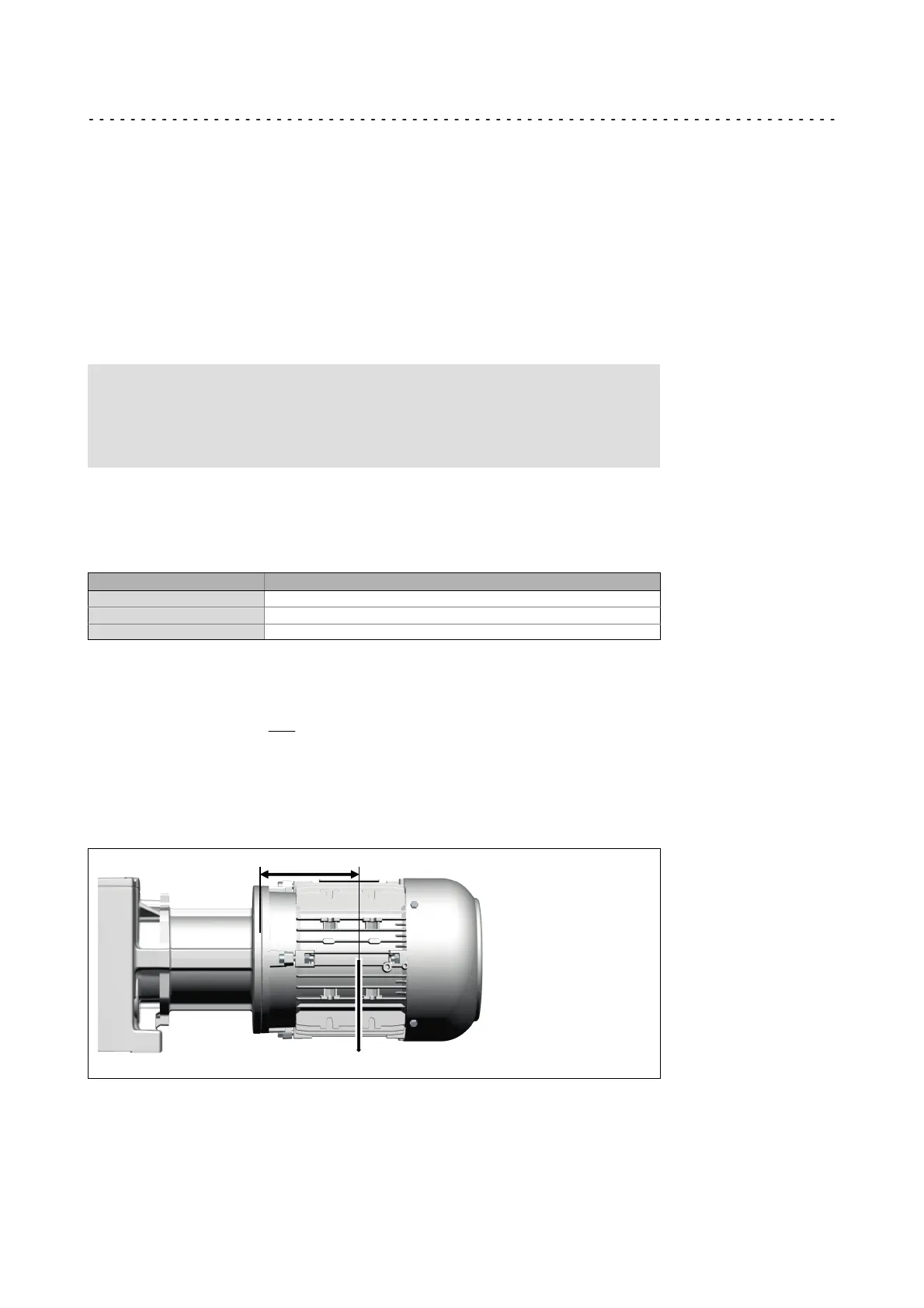

The position of the motor‘s centre of gravity, including all motor options, must be

calculated. If the distance of the centre of gravity L

Tab

is greater, the permissible force

must be reduced as follows.

F

Mzul

+ k

Lastfall

@ F

MTab

@

L

Tab

L

v k

Lastfall

@ F

MTab

If forces act from several directions, e.g. in the case of a moving horizontal travelling

drive, the acting forces have to be added vectorially (e.g. vertical force due to weight plus

horizontal acceleration force).

F

Mperm

corresponds to the maximum value of the forces added vectorially!

L

F

M

If the permissible force F

Mperm

is exceeded, the motor has to be supported in a suitable,

distortion−free fashion!

Loading...

Loading...