16

ENGLISH

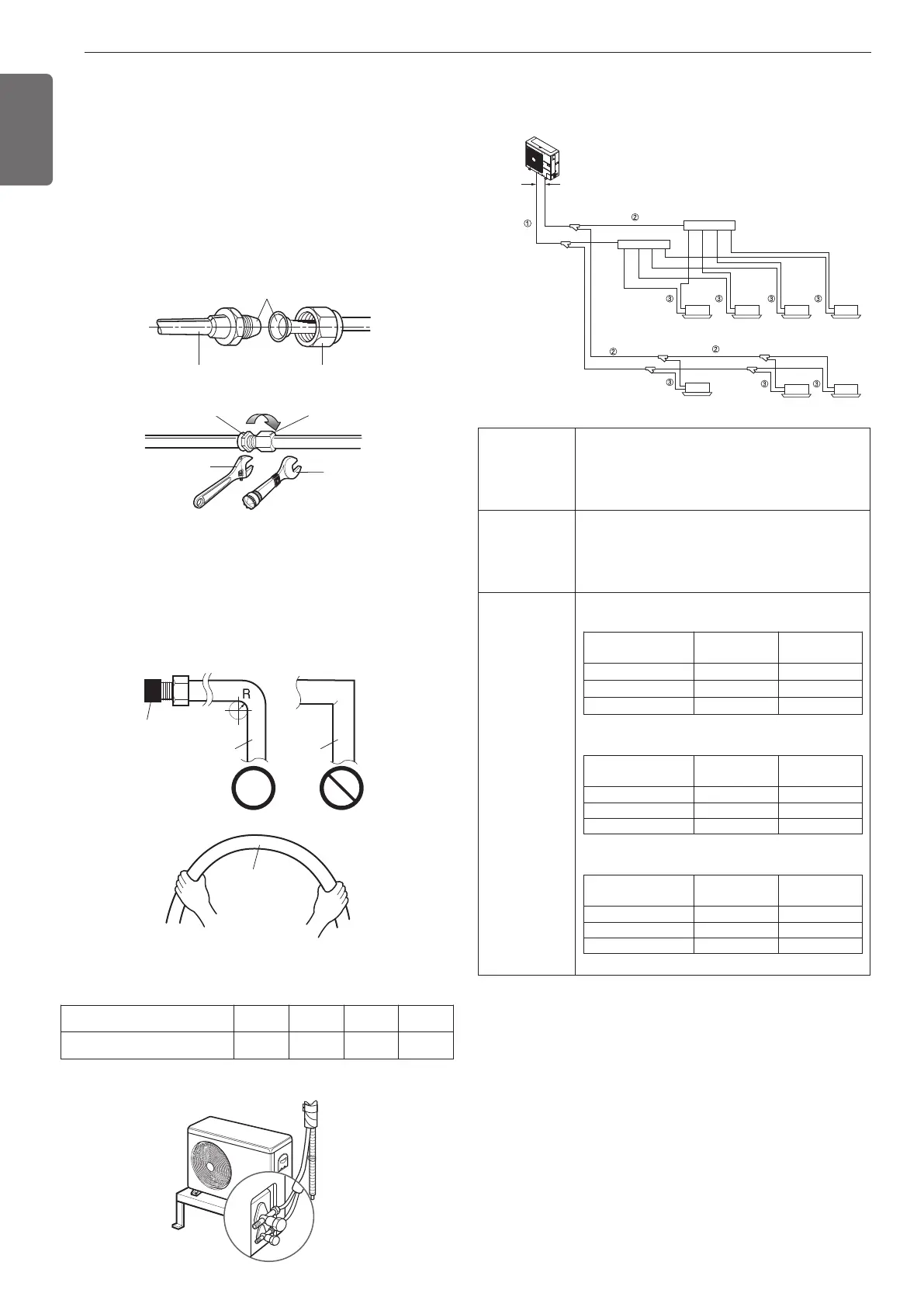

The center shall match

Refrigerant pipe Flare nut

Socket flare Flare nut

Torque wrench

Monkey spanner

Do not bend the pipe 2 or more times, and work with the bigger

radius.

If the pipe is bent, the cooling/heating performance is degraded, and it

may cause failure.

Do not remove the cap of the flare surface until the locking work.

If dust, earth, etc. enters inside the pipe, it may cause failure.

Bend carefully along the wall, and connect to the outdoor unit valve.

Refrigerant pipe locking torque

Pipe outer diameter Ø 6.35 Ø 9.52 Ø 12.7 Ø 15.88

Torque 16±2 38±4 55±6 75±7

h The exterior of the product may be different for each model.

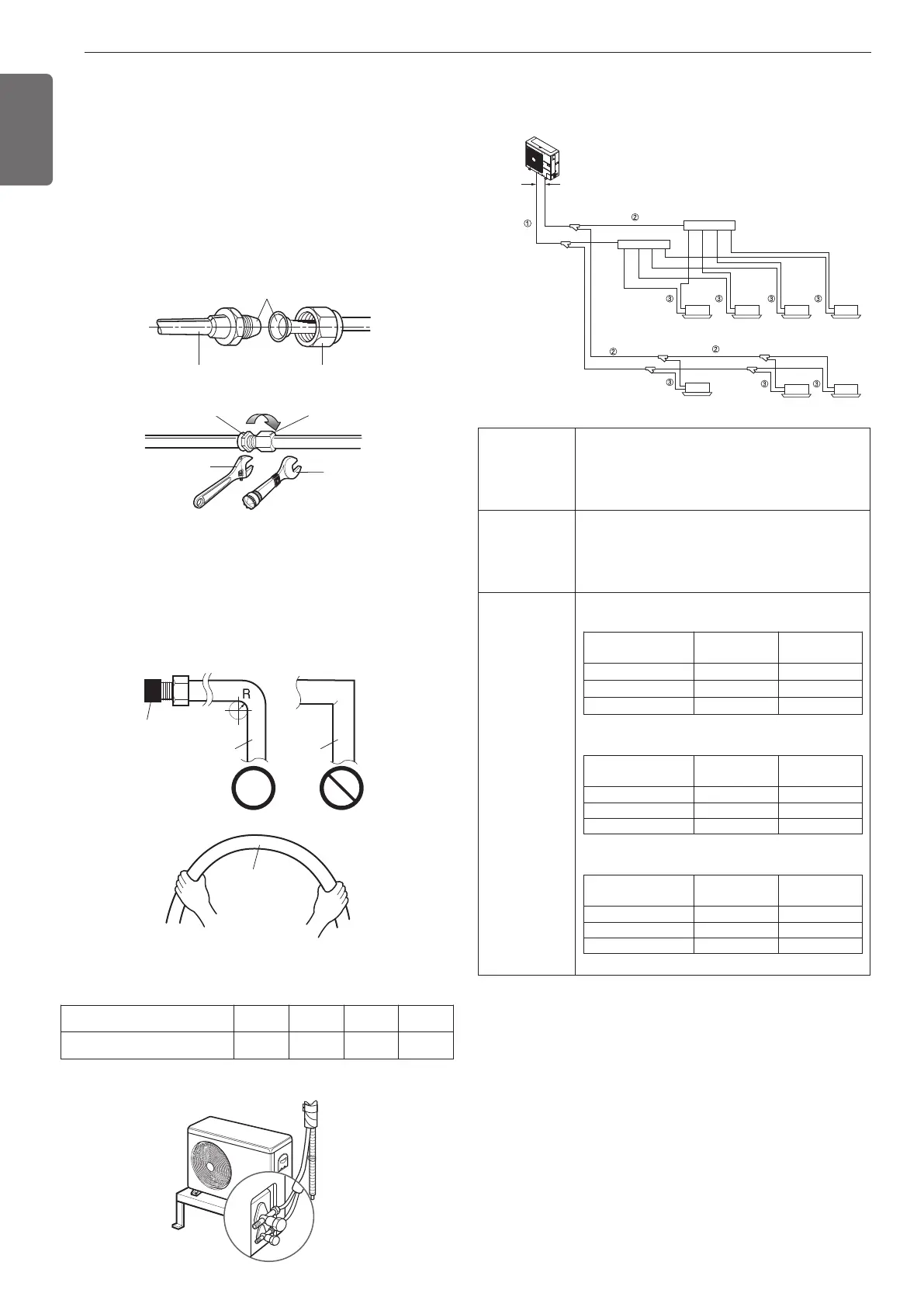

Piping parts

Name

① Main pipe

② Branching pipe

③ Indoor unit connecting pipe

Selection

of

pipe size

Outdoor unit

capacity[HP]

Liquid pipe

[mm(inch)]

Gas pipe

[mm(inch)]

6

Ø 9.52(3/8) Ø 19.05(3/4)

5

Ø 9.52(3/8) Ø 15.88(5/8)

4

Ø 9.52(3/8) Ø 15.88(5/8)

① Size of main pipe

② Pipe size of between branching sections

③ Connecting pipe size of indoor unit

Indoor unit capacity

[kW(Btu/h)]

Liquid pipe

[mm(inch)]

Gas pipe

[mm(inch)]

≤ 5.6(19 100)

Ø 6.35(1/4) Ø 12.7(1/2)

< 16.0(54 600)

Ø 9.52(3/8) Ø 15.88(5/8)

< 22.4(76 400) Ø 9.52(3/8) Ø 19.05(3/4)

Indoor unit capacity

[kW(Btu/h)]

Liquid pipe

[mm(inch)]

Gas pipe

[mm(inch)]

≤ 5.6(19 100)

Ø 6.35(1/4) Ø 12.7(1/2)

< 16.0(54 600)

Ø 9.52(3/8) Ø 15.88(5/8)

≤ 22.4(76 400)

Ø 9.52(3/8) Ø 19.05(3/4)

① Outdoor unit ’ 1st branching section

② Branching section

’ Branching section

③ Branching section

’ Indoor unit

Outdoor unit

Gas pipe

Main pipe

Liquid pipe

Branching

pipe

Branching

pipe

Indoor unit

Selection of Refrigerant Piping

U36A Chassis (1 FAN model)

Connect the refrigerant pipe, and after the refrigerant leakage

inspection, cover with insulation material and wrap with vinyl tape.

Tighten the flare nut according to the specified torque. (until there is a

"click" sound in the torque wrench part)

PIPE CONNECTIONS BETWEEN

INDOOR AND OUTDOOR UNIT

Loading...

Loading...