29

ENGLISH

Display Title Cause of Error

Indoor unit related error

0 1 -

Air temperature sensor of indoor unit

Air temperature sensor of indoor unit is open or short.

0 2 -

Inlet pipe temperature sensor of indoor unit

Inlet pipe temperature sensor of indoor unit is open or short.

0 3 -

Communication error : wired remote controller

÷

indoor unit

Failing to receive wired remote controller signal in indoor unit PCB

0 4 -

Drain pump

Malfunction of drain pump

0 5 -

Communication error : outdoor unit

÷

indoor unit

Failing to receive outdoor unit signal in indoor unit PCB

0 6 -

Outlet pipe temperature sensor of indoor unit

Outlet pipe temperature sensor of indoor unit is open or short.

0 9 -

Indoor EEPROM Error

In case when the serial number marked on EEPROM of Indoor unit is 0 or

FFFFFF.

1 0 -

Poor fan motor operation

Disconnecting the fan motor connector/Failure of indoor fan motor lock

Outdoor unit related error

2 1 *

Outdoor Unit Inverter Compressor IPM Fault

Outdoor Unit Inverter Compressor Drive IPM Fault

2 2 *

Inverter Board Input Over Current(RMS) of Outdoor

Unit

Outdoor Unit Inverter Board Input Current excess (RMS)

2 3 *

Outdoor Unit Inverter Compressor DC link Low Voltage

DC charging is not performed at Outdoor Unit after starting relay turn on.

2 4 *

Outdoor Unit High Pressure Switch

System is turned off by Outdoor Unit high pressure switch.

2 5 *

Outdoor Unit Input Voltage High/ Low Voltage

Outdoor Unit input voltage is over 487 V or below 270 V.

2 6 *

Outdoor Unit Inverter Compressor Start Failure

The First Start Failure by Outdoor Unit Inverter Compressor Abnormality

2 9 *

Outdoor Unit Inverter Compressor Over Current

Outdoor Unit Inverter Compressor Fault OR Drive Fault

* Refer to the Indoor manual for some Indoor Error code.

Self-Diagnosis Function

Error Indicator

- This function indicates types of failure in self-diagnosis and occurrence of failure for air condition.

- Error mark is displayed on display window of indoor units and wired remote controller, and 7-segment LED of outdoor unit control board as

shown in the table.

- If more than two troubles occur simultaneously, lower number of error code is first displayed.

- After error occurrence, if error is released, error LED is also released simultaneously.

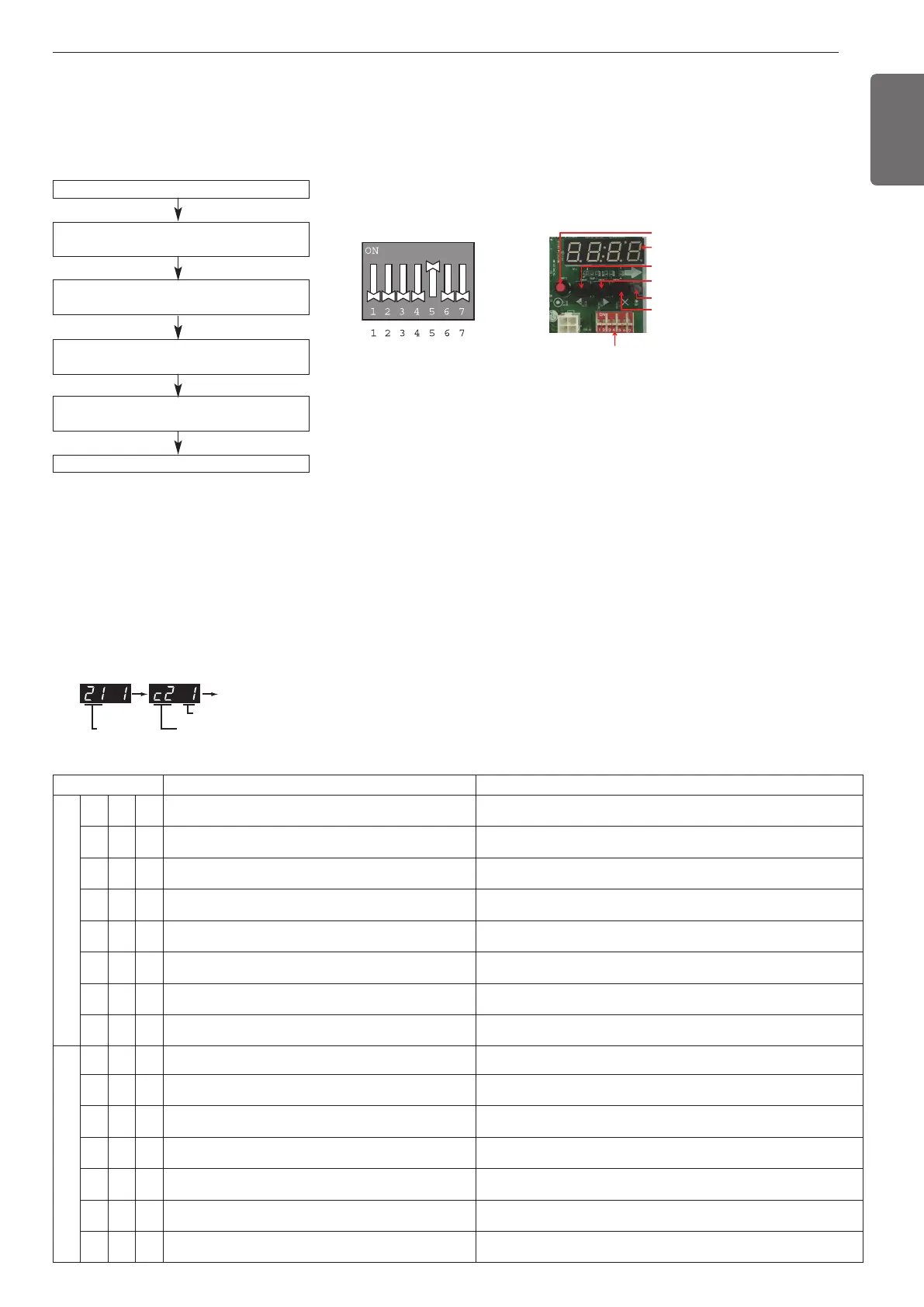

Error Display

1st, 2nd, 3rd LED of 7-segment indicates error number, 4th LED indicates unit number.

Ex)

Error No. of Compressor

Error No.

Error No. of Unit

Repeat

Master unit PCB DIP switch on : No.5

Select the mode using ‘▶’, ‘◀’ Button :

“Func” Push the ‘●’ button

Select the Function using ‘▶’, ‘◀’ Button :

“Fn25” Push the ‘●’ button

Select the Option using ‘▶’, ‘◀’ Button :

“hEAt” Push the ‘●’ button

Heating priority operation is set

Select the Option using ‘▶’, ‘◀’ Button :

“on” , “oFF” Push the ‘●’ button

Priority Heating Operation

This is the function that gives priority to the hot water supply operation (heating) for the model that cannot simultaneously operate heating and

cooling.

This function enables the appliance to supply hot water and operate indoor cooling by alternatevely heating using hydrokit and cooling operation.

Mode setting method

Setting the function

Select the mode/function/option/value using ‘▶’, ‘◀’ Button and

confirm that using the ‘●’ button after DIP switch No.5 is turned on.

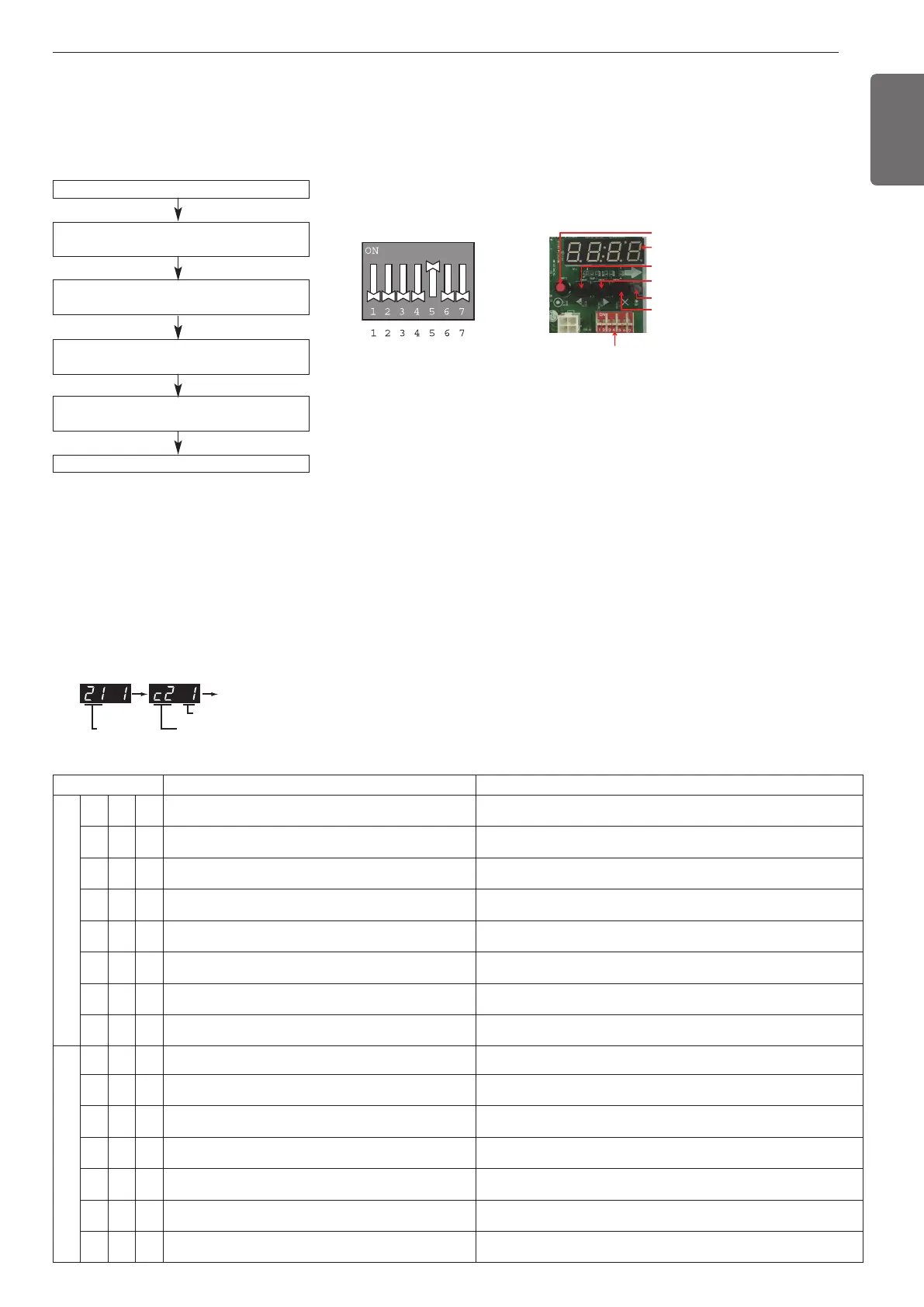

DIP SWITCH

7-Segment

SW01C ( Ɨ: confirm)

SW02C ( ȭ: backward)

SW04C ( X : cancel)

SW01D (reset)

SW03C ( ȯ: forward)

Loading...

Loading...