31

COMPILER TECO/ATI ENDORSEDDATE

23.06.2003

REG. CODE

1-5302-607

MODEL N°

50889

DATE OF ISSUE

06-03

REVISION 00

XIII

55

56

57

58 59

kgm 2,2 (Nm 21,6)

ENGINE ASSEMBLY

Notice: These instructions are valid for engines up-dated

prior to the publication of this manual. Any modifications

must be checked on the technical circulars.

Before assembling the engine carefully clean all parts

and dry them with compressed air. Lubricate moving parts

to prevent seizing when starting up. Replace the gaskets

with new ones each time the engine is assembled.

Use torque wrenches to ensure that the correct tightening

torques are applied.

Preparing the crankcase

Clean the mating surfaces of sealing compound residues or other

foreign material using a copper scraper or fine emery stone. Make

sure that the oil passages are open and free of built-up deposits.

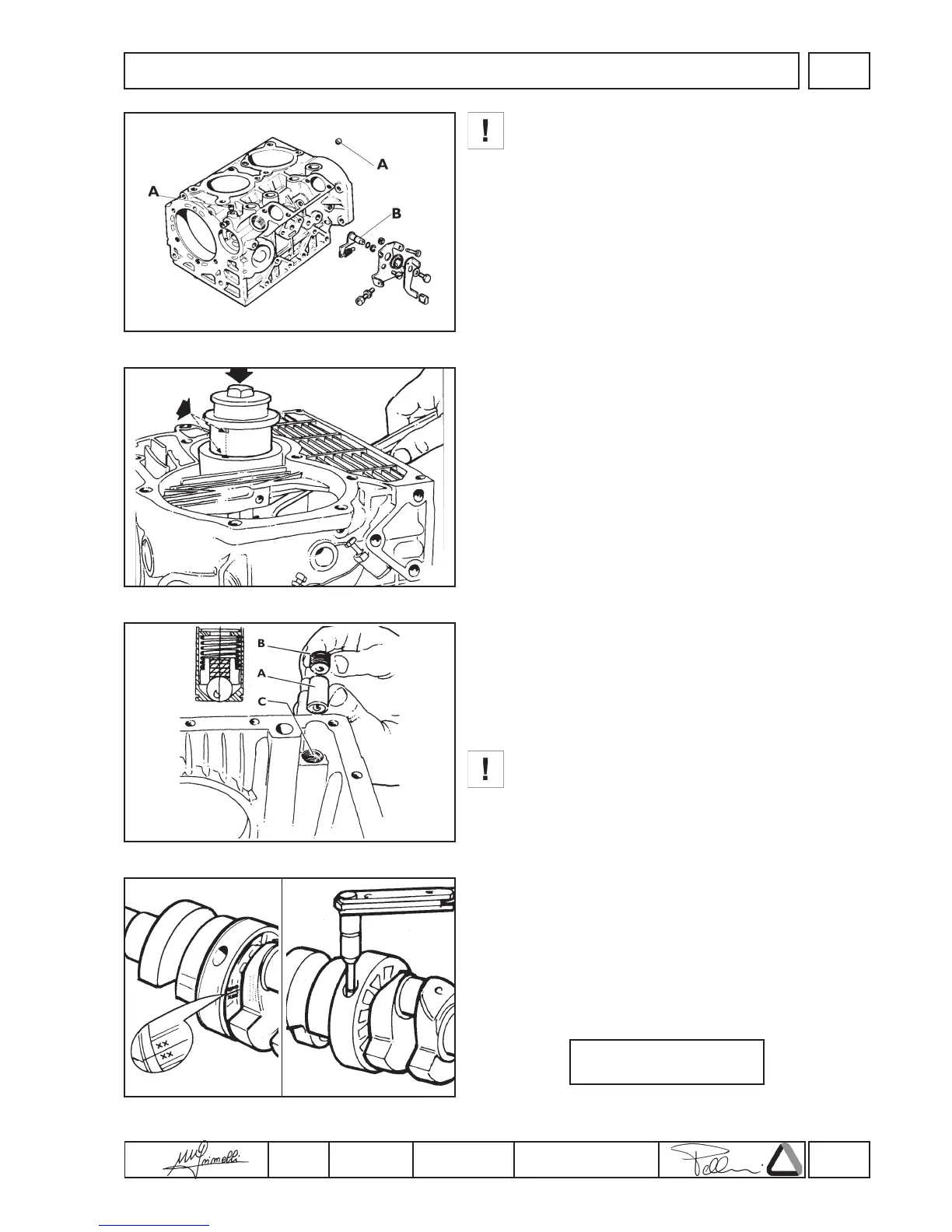

1.Fit the plugs (A, fig.55) in their holes.

2.Insert the internal accelerator lever (B, fig.55) into the crankcase

with its spring taking care to protect the oil seal O-ring from

damage.

Complete the external assembly with plate, spring, lever, etc. as

shown in figure 55.

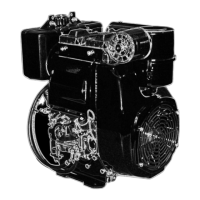

3.Mount the bearing bush (gear train side) using either a

standard press or a made-to-measure punch as shown in

figure 56. Fit the bush by matching the hole with the passage on

the crankcase. Bushes with standard or smaller internal

diameters can be ordered as required.

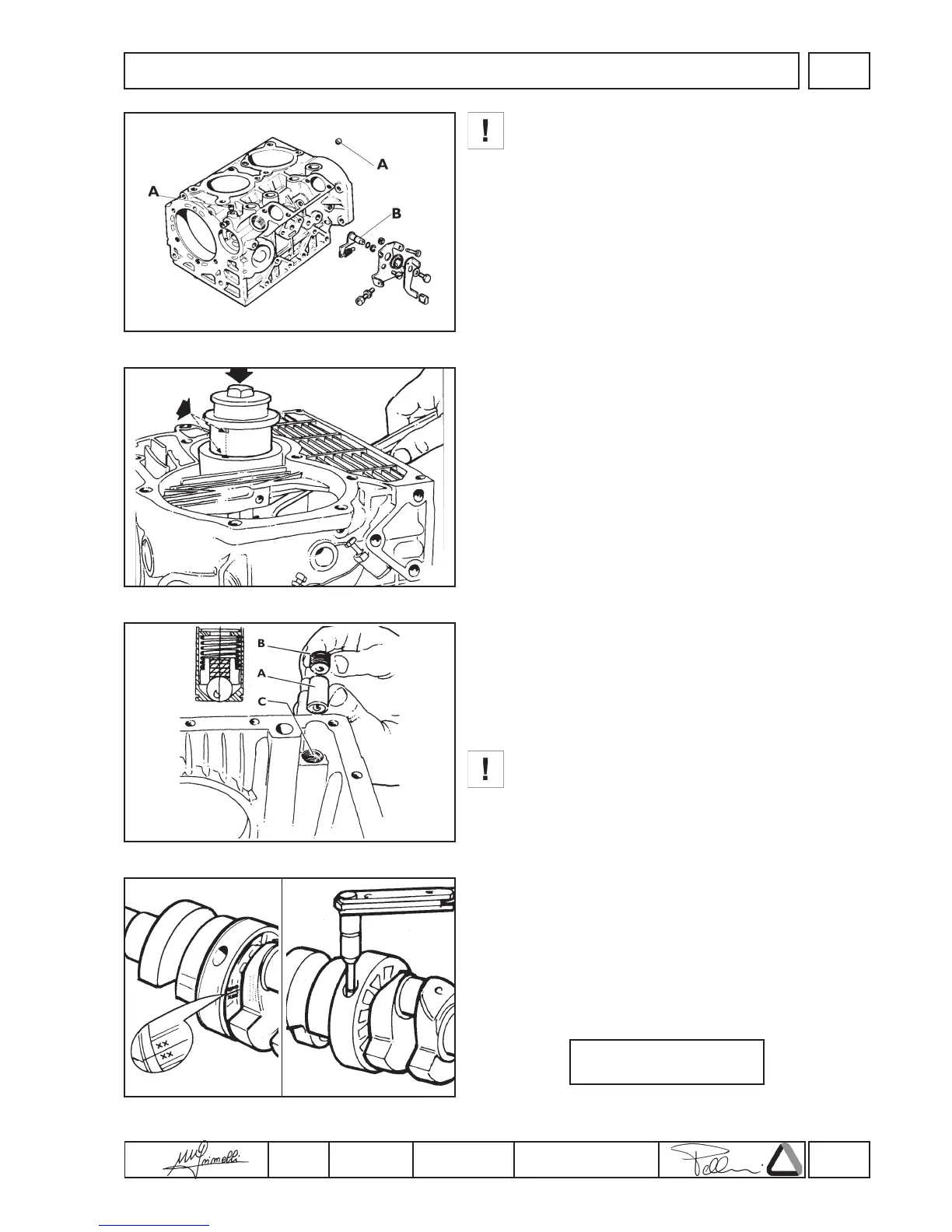

4.Insert the complete oil pressure relief valve (A, fig. 57) into its

housing (C, fig.57). Make sure that the valve ball seat is free of

dirt that could reduce the effectiveness of the pressure seal.

Secure the oil pressure valve with the relative screw (B, fig. 57).

5.Insert the cylinder studs and the centring pins.

Central main bearings

Fit the shells into their seats and coat with a thin film of oil.

The reference numbers (fig.58) must be aligned on each half-shell,

making sure that the oil passages match the corresponding

openings in the crankcase. Torque the bearing assembly bolts (fig.

59) to:

A warped oil retainer may allow the introduction of air into

the engine thus causing crankcase ventilation problems.

Use genuine oil retainers with the LOMBARDINI.

Loading...

Loading...