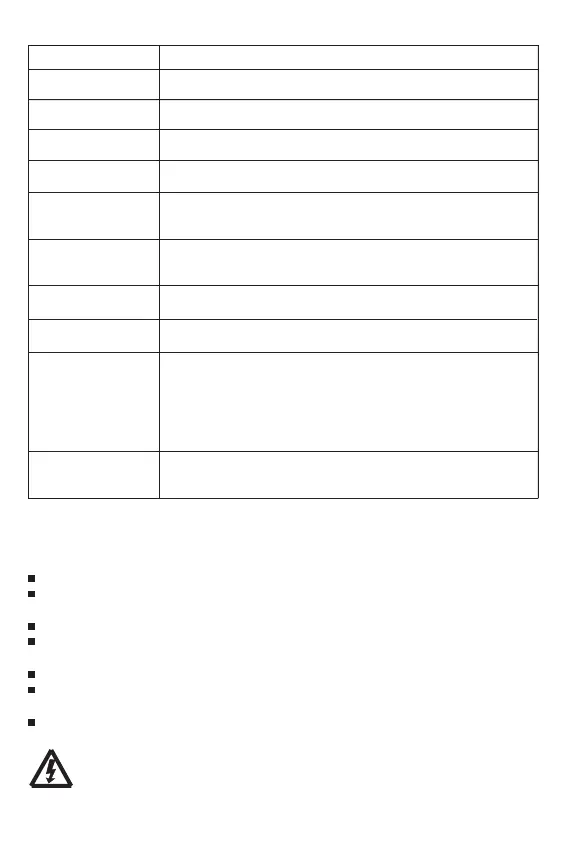

7.2 Protection

PV Short Circuit

PV Reverse Polarity

PV Over Current

The controller will limit charging power in rated charge power.

An over-sized PV array will not operate at maximum power point.

When PV short circuit occurs, the controller will stop charging.

Remove it to start normal operation.

Fully protection against PV reverse polarity, no damage to the

controller. Correct the connection to start normal operation.

Fully protection against batter y reverse polarity, no damage to the

controller. Correct the connection to start normal operation.

If there are other energy sources to charge the battery, when the

battery voltage exceeds 15.8 / 31.3V, the controller will stop charging

to protect the battery from overcharging damage.

When battery voltage drops to the setting voltage point of low voltage

disconnect ,the controller will stop discharging to protect the battery

from over discharging damage.

If the load current exceeds the maximum load current rating 1.25 times,

the controller will disconnect the load.

Once the load short circuit happens , the load shor t circuit protection

will start automatically.

The controller detects the internal temperature through internal sensor,

when the temperature exceeds the setting value, the charging current

will lower down followed by the decrease of temperature, so as to

control the controller temperature rise, when the internal

temperature exceeds the setting over temperature protection

threshold, the controller stops working and restores after the

temperature is lowered.

's

If the temperature sensor is short-circuited or damaged, the controller

will be charging or discharging at the default temperature 25℃ to

prevent the battery damaged from overcharging or over discharged.

Protection

Description

Battery Reverse Polarity

Battery Over voltage

Battery Over discharge

Load Over Current

Protection

Load Short Circuit

Protection

Over Temperature

Protection

Damaged Remote

Temperature Sensor

WARNING:Risk of electric shock!

Make sure that all the power is turned off before above operations,

and then follow the corresponding inspections and operations.

7.3 Maintenance

Make sure no block on air-flow around the controller. Clear up any dirt and fragments on radiator.

Check all the naked wires to make sure insulation is not damaged. Repair or replace some

wires if necessary.

Tighten all the terminals. Inspect for loose, broken, or burnt wire connections.

Check and confirm that LCD is consistent with required. Pay attention to any

troubleshooting or error indication .Take corrective action if necessary.

Confirm that all the system components are ground connected tightly and correctly.

Confirm that all the terminals have no corrosion, insulation damaged, high

temperature or burnt/discolored sign, tighten terminal screws to the suggested torque.

Check for dir t, nesting insects and corrosion. If so, clear up in time.

The following inspections and maintenance tasks are recommended at least two times per year

for best performance.

16

Loading...

Loading...