Refer to the table

at

right to Select the Pro-

However, the appropriate speed may differ

Mild

Steel

per speed for the workpiece to be cut.

with the type

or

thickness of the work-

piece. In general, higher speeds will allow

Stainless

Steel

you to cut workpieces faster but the

Aluminum

service life of the blade will be reduced.

Plastics

CAUTION

:

Adjust the speed adjusting dial only within the range of numbers

1

through

6.

Do

not

force the dial beyond this range or damage to the tool may result.

Cutting operation

CAUTION

:

0

Always hold the tool with the base flush with the workpiece. Failure to do

so

may cause

.Advance the tool very slowly when cutting curves or scrolling. Forcing the tool may

a

slanted cutting surface and blade breakage.

cause

a

slanted cutting surface and blade breakage.

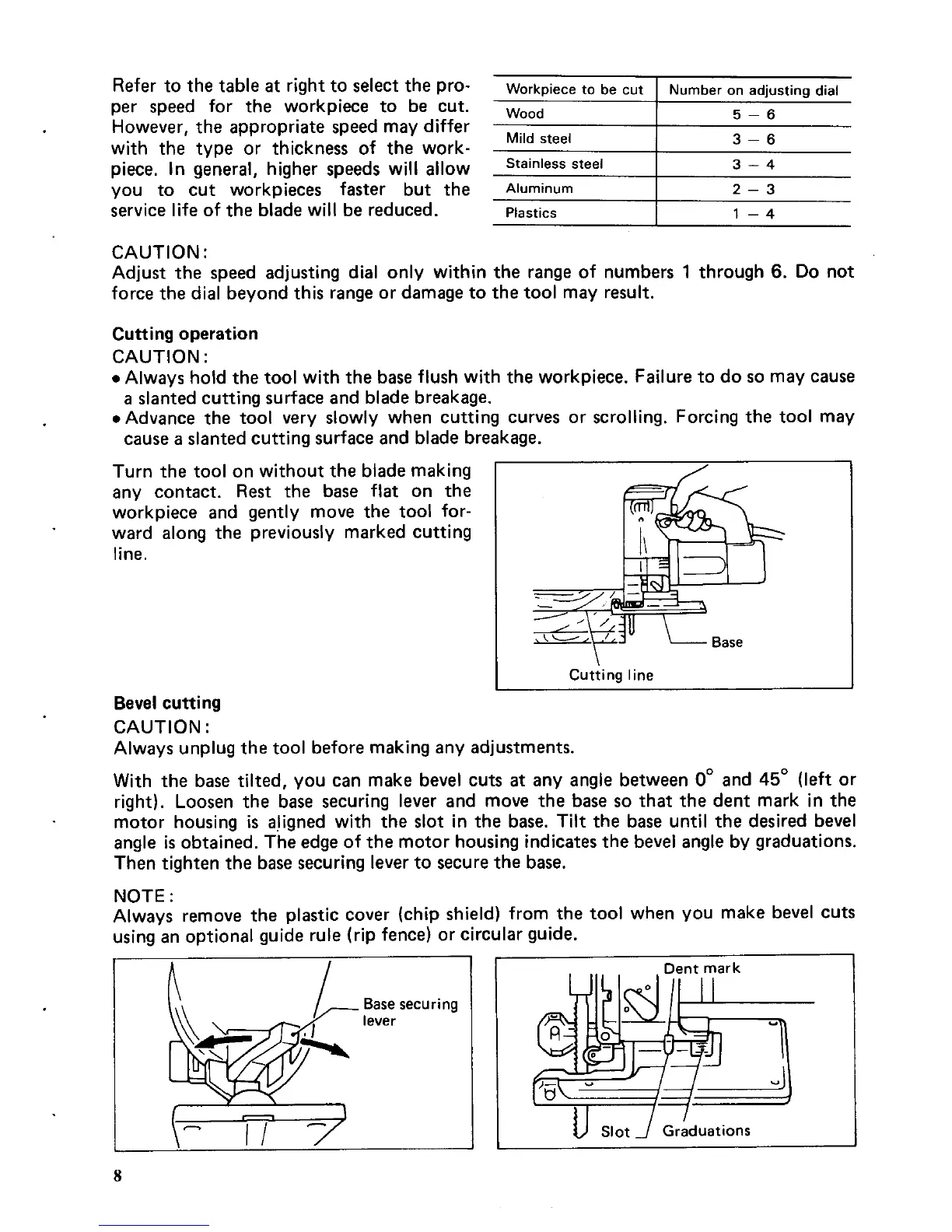

Turn the tool on without the blade making

any contact.

Rest

the base flat on the

workpiece and gently move the tool for-

ward along the previously marked cutting

line.

Cutting line

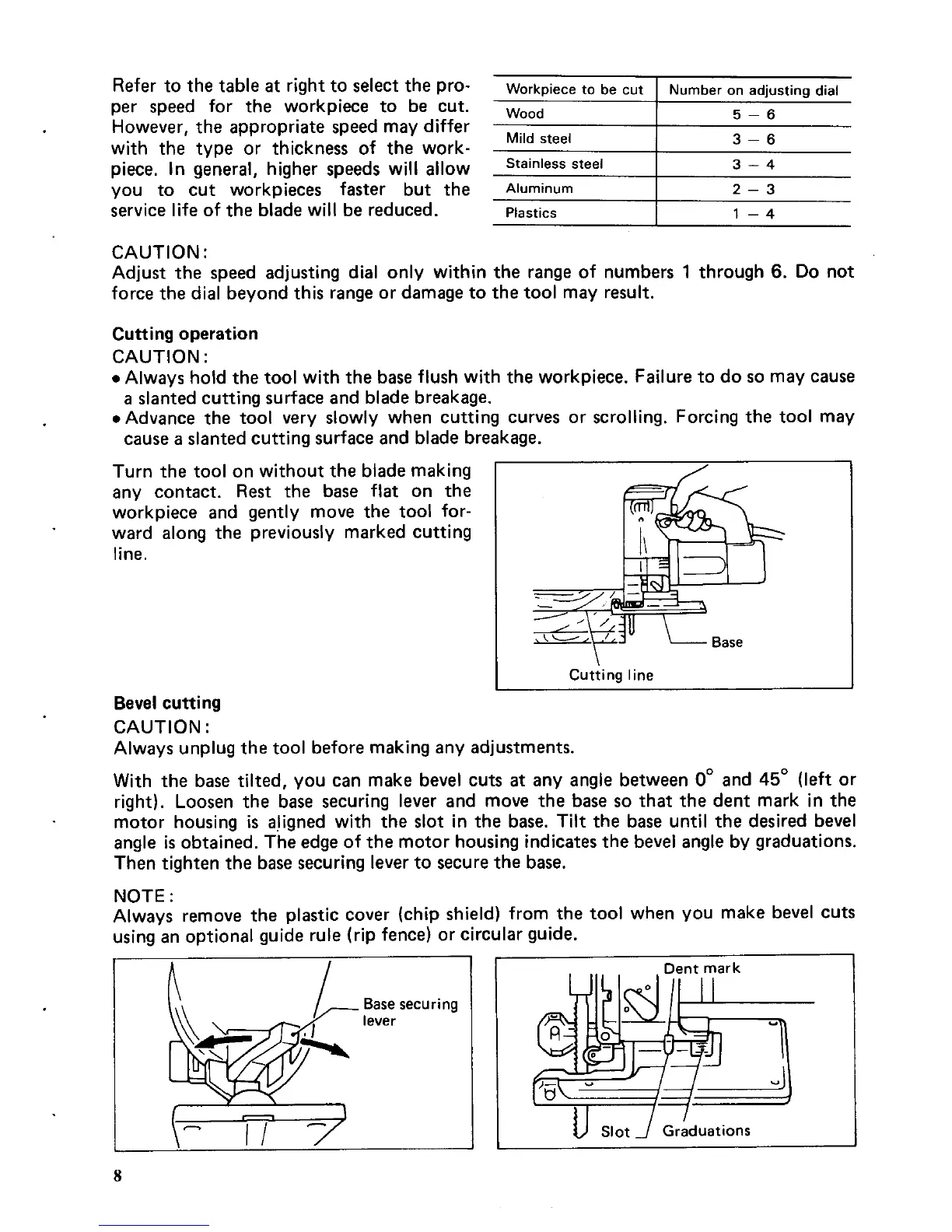

Bevel

cutting

CAUTION

:

Always unplug the tool before making any adjustments.

With the base tilted, you can make bevel cuts

at

any angle between

0'

and

45'

(left or

right). Loosen the base securing lever and move the base

so

that the dent mark in the

motor housing

is

aligned with the slot in the base. Tilt the base until the desired bevel

angle

is

obtained. The edge of the motor housing indicates the bevel angle by graduations.

Then tighten the base securing lever to secure the base.

NOTE

:

Always remove the plastic cover (chip shield) from the tool when you make bevel cuts

using an optional guide rule (rip fence) or circular guide.

.

Base

securing

lever

8

Loading...

Loading...