8 ENGLISH

This tool has three action modes.

•

Drilling mode (rotation only)

•

Hammer drilling mode (rotation with hammering)

• Screwdriving mode (rotation with clutch)

action mode changing ring and align the mark that you

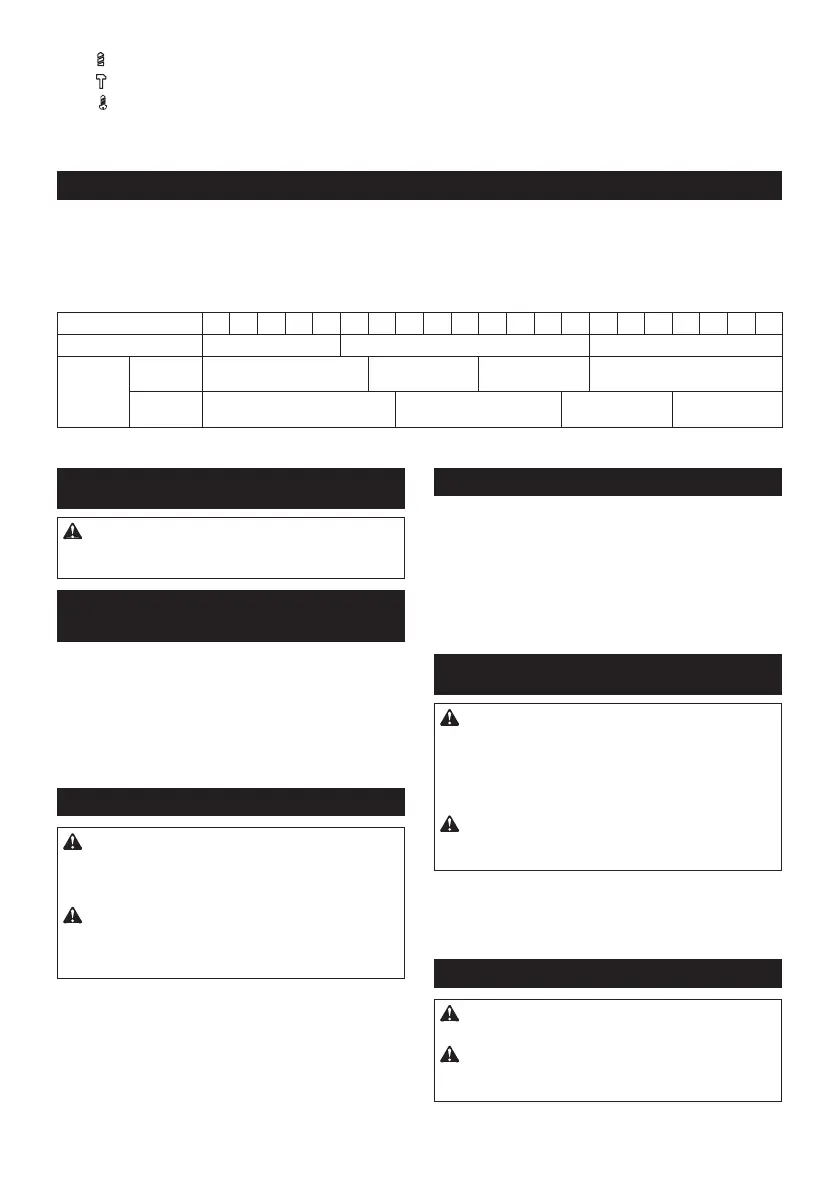

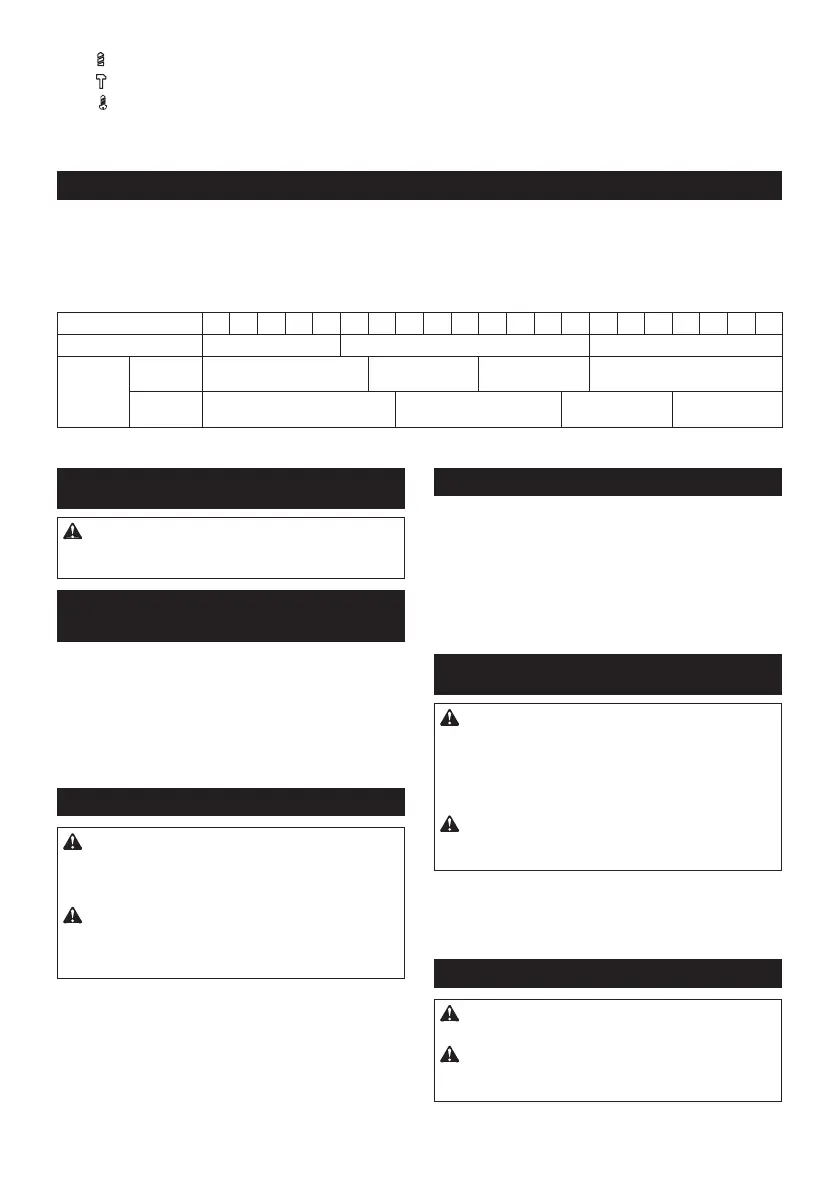

Adjusting the fastening torque

Fig.8: 1.2.

ring 3. Graduation 4.

fastening torque at 1 and maximum torque at 21.

Before actual operation, drive a trial screw into your

material or a piece of duplicate material to determine

which torque level is required for a particular applica-

tion. The following shows the rough guide of the rela-

Graduation 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Machine screw M5 M6

Wood

screw

Soft wood

(e.g. pine)

– ø3.5 x 22 –

Hard wood

(e.g. lauan)

– ø3.5 x 22 –

ASSEMBLY

CAUTION: Always be sure that the tool is

before carrying out any work on the tool.

Installing or removing driver bit/

drill bit

Optional accessory

Fig.9: 1. Sleeve 2. Close 3. Open

Turn the sleeve counterclockwise to open the chuck

as it will go. Turn the sleeve clockwise to tighten the

counterclockwise.

Installing hook

CAUTION: When installing the hook, always

If not, the hook

CAUTION: Use the hanging/mounting parts

for their intended purposes only. Using for unin-

tended purpose may cause accident or personal

Fig.10: 1. Groove 2. Hook 3. Screw

The hook is convenient for temporarily hanging the tool.

the hook, insert it into a groove in the tool housing on

either side and then secure it with a screw. To remove,

loosen the screw and then take it out.

Installing driver bit holder

Optional accessory

Fig.11: 1.2.

on either right or left side and secure it with a screw.

OPERATION

CAUTION:

Always insert the battery cartridge

all the way until it locks in place. If you can see the red

seen. If not, it may accidentally fall out of the tool, causing

CAUTION: When the speed comes down

extremely, reduce the load or stop the tool to

avoid the tool damage.

control the twisting action.

Fig.12

Screwdriving operation

CAUTION: Adjust the adjusting ring to the

proper torque level for your work.

CAUTION: Make sure that the driver bit is

inserted straight in the screw head, or the screw

and/or driver bit may be damaged.

Loading...

Loading...