27

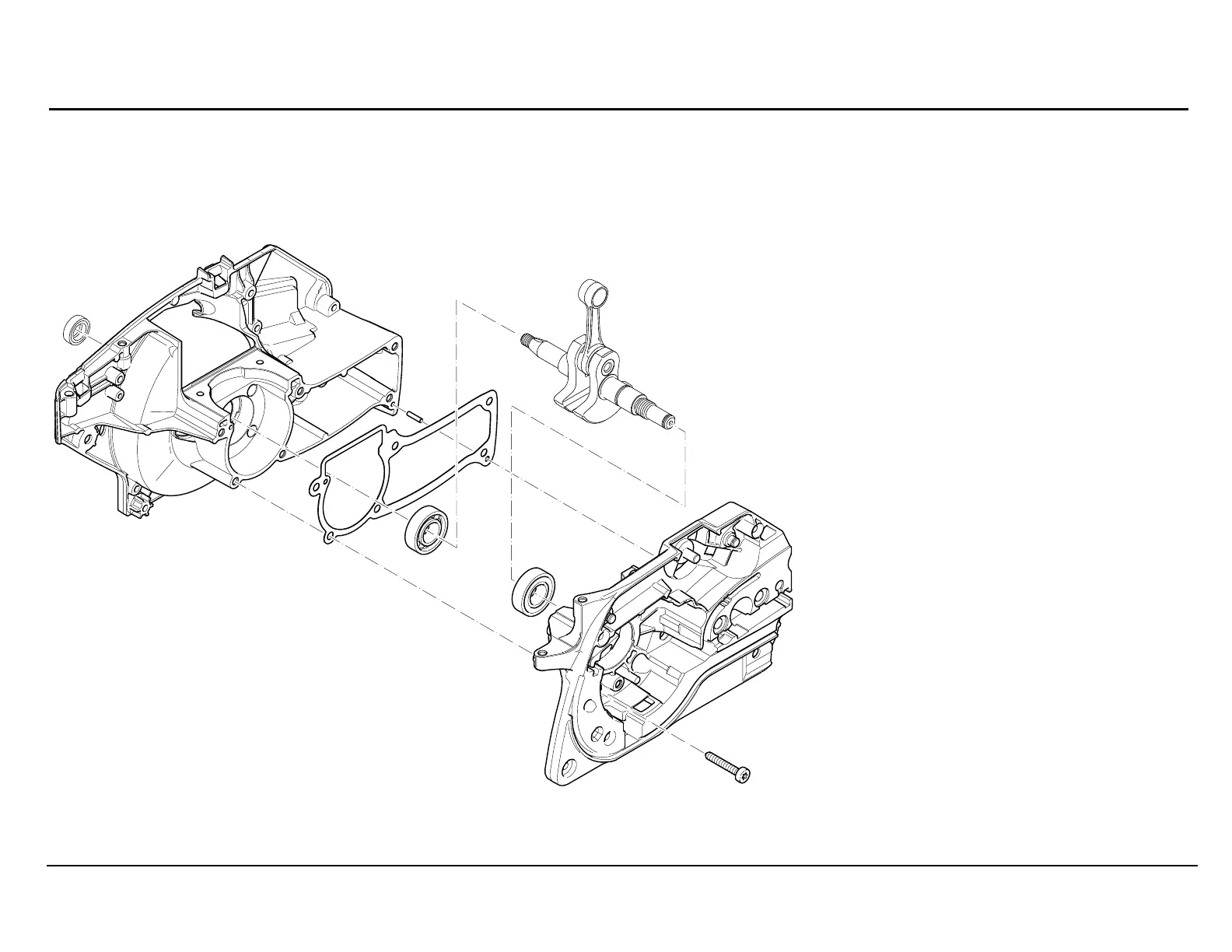

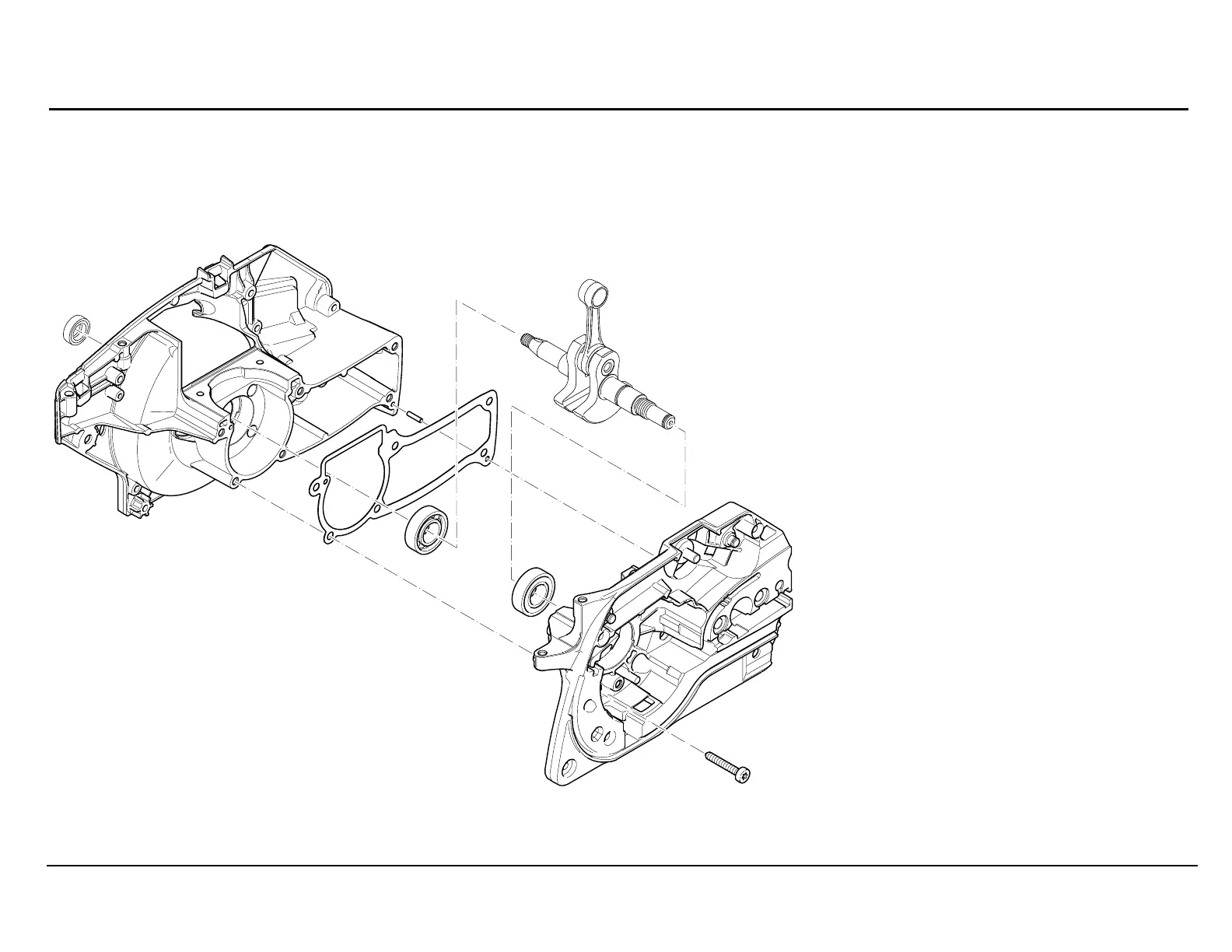

The crankcase magnet side and cylinder side

are held together with six screws 1.

Two pins 2 ensure proper fitting.

To assemble the ball bearings please note the

following repair instructions

• Press a ball bearing onto the crankshaft

clutch-side by using an assembling bush.

Press only on the internal ring of the

bearing.

Note: Put a wedge between the

crankwebs.

• Heat the crankcase clutch-side up to 150 -

160

0

Celsius (302-320

0

Fahrenheit),

evenly coat the external ring of the ball

bearing with Loctite 601 and slide it

together with the crankshaft in the warm

crankcase without any effort.

Note: Degrease both ball bearings before

coating the external ring with Loctite 601.

• Heat the crankcase magneto-side up to

150 -160

0

Celsius (302-320

0

Fahrenheit),

evenly coat the external ring of the ball

bearing with Loctite 601 and slide it in the

warm crankcase without any effort.

• Assemble the crankcase halves. Put a

wedge between the crankwebs

use a new gasket. After bolting the

crankcase sides together, cut off the flash 3.

Makita is providing crankcases as a spare part

the ball bearings are already glued into

the crankcase

Loading...

Loading...