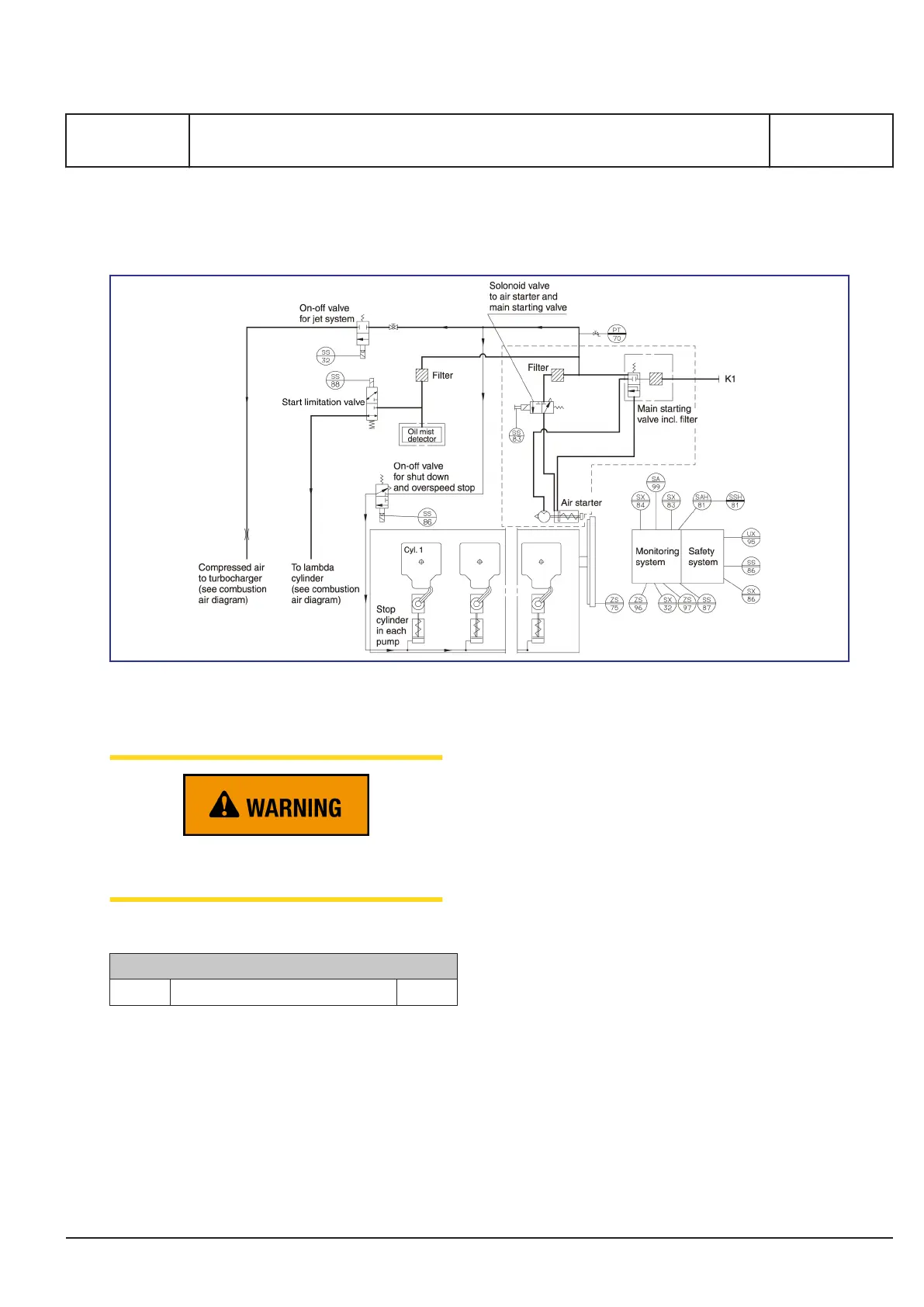

Compressed air system

Figure 1: Diagram for 10 bar compressed air system (for guidance only, please see the plant specific engine diagram)

Air supply!

Air supply must not be interrupted when engine

is running

Pipe description

Pipe description

K1 Compressed air inlet DN 50

Table 1: Flange connections are standard according to DIN 2501

General

The compressed air system on the engine consists

of a starting system, starting control system and

safety system. Further, the system supplies air to

the jet system and the stop cylinders on each fuel

injection pump. On 8 and 9 cylinder engines air is

supplied to the oil mist detector through a reduction

valve.

The compressed air is supplied from the starting air

receivers (30 bar) through a reduction station,

where from compressed air at 10 bar is supplied to

the engine. The reduction station should be located

as near the starting air receiver as possible.

To avoid dirt particles in the internal system, a

strainer equipped with a drain valve is mounted in

the inlet line to the engine.

Starting system

The engine is started by means of a built-on air

starter, which is a turbine motor with gear box,

safety clutch and drive shaft with pinion. Further,

there is a main starting valve.

Control system

The air starter is activated electrically with a pneu-

matic 3/2-way solenoid valve. The valve can be

activated manually from the starting box on the

engine, and it can be arranged for remote control,

manual or automatic.

MAN Diesel & Turbo

3700205-5.1

Page 1 (2)

Compressed air system

B 14 00 0

L27/38S, L27/38

2015.11.09 - Tier II, Stationary, Low pressure, Standard

Loading...

Loading...