IOMM AGR-1 AGR 070A through 100A 95

Unit Service

CAUTION

1. Service on this equipment is to be performed by qualified refrigeration personnel familiar with

equipment operation, maintenance, correct servicing procedures, and the safety hazards inherent

in this work. Causes for repeated tripping of safety controls must be investigated and corrected.

2. Disconnect all power before doing any service inside the unit.

3. Anyone servicing this equipment shall comply with the requirements set forth by the EPA in

regards to refrigerant reclamation and venting.

Filter-Driers

A replacement of the filter-drier is recommended any time excessive pressure drop is read across the

filter-drier and/or when bubbles occur in the sightglass with normal subcooling. The maximum

recommended pressure drops across the filter-drier are as follows:

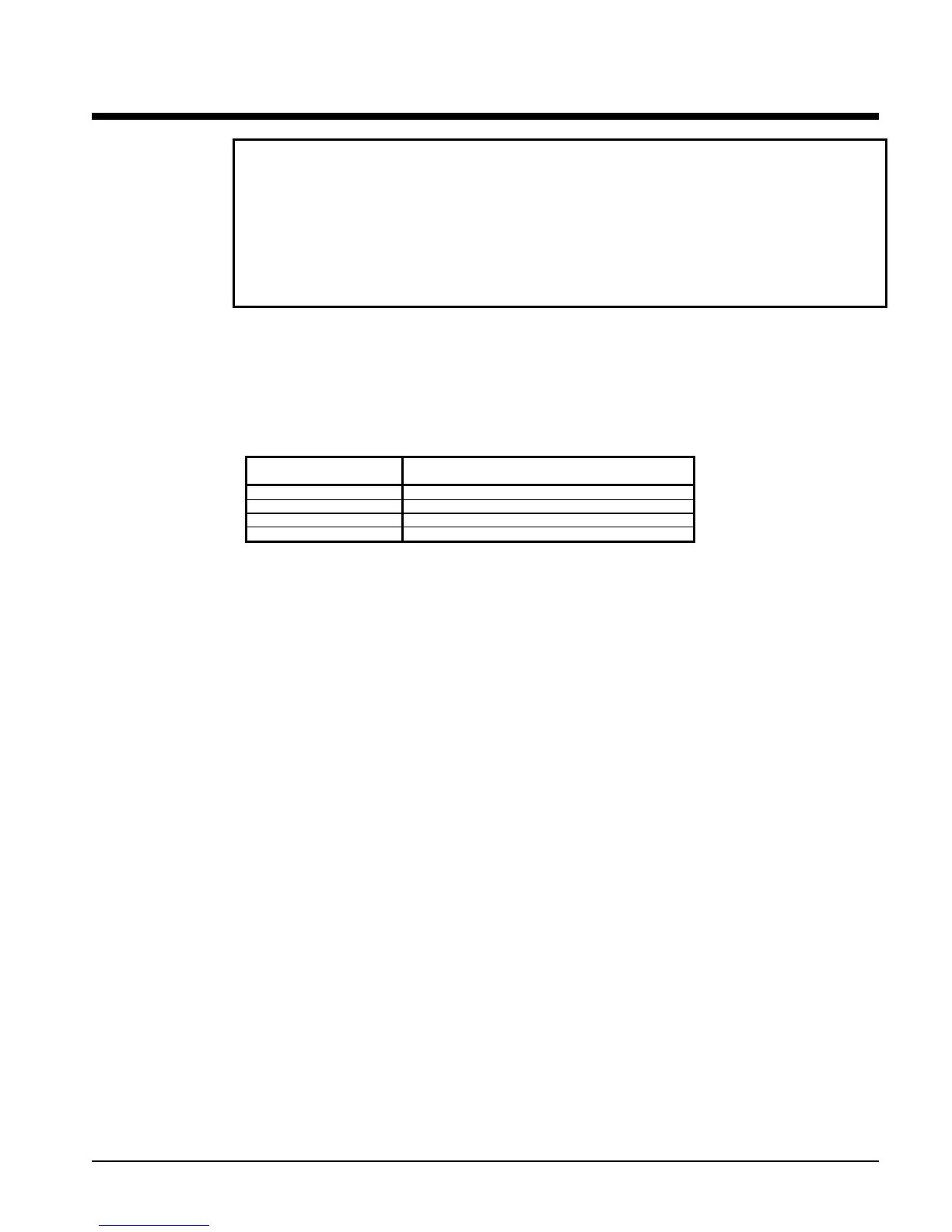

Table 54, Filter-Drier Pressure Drop

PERCENT CIRCUIT MAXIMUM RECOMMENDED PRESSURE

LOADING (%) DROP ACROSS FILTER DRIER PSIG (kPa)

100% 10 (69)

75% 8 (55.2)

50% 5 (34.5)

25% 4 (27.6)

The filter-drier should also be changed if the moisture indicating liquid line sightglass indicates

excess moisture in the system.

During the first few months of operation the filter-drier replacement may be necessary if the pressure

drop across the filter-drier exceeds the values listed in the paragraph above. Any residual particles

from the condenser tubing, compressor and miscellaneous components are swept by the refrigerant

into the liquid line and are caught by the filter-drier.

Liquid Line Solenoid Valve

The liquid line solenoid valves that shut off refrigerant flow in the event of a power failure does not

normally require any maintenance. The solenoids may, however, require replacement of the solenoid

coil or of the entire valve assembly.

The solenoid coil can be checked to see that the stem is magnetized when energized by touching a

screwdriver to the top of the stem. If there is no magnetization either the coil is bad or there is no

power to the coil.

The solenoid coil may be removed from the valve body without opening the refrigerant piping after

pumpdown. For personal safety shut off and lock out the unit power.

The coil can then be removed from the valve body by simply removing a nut or snap-ring located at

the top of the coil. The coil can then be slipped off its mounting stud for replacement.

To replace the entire solenoid valve follow the steps involved when changing a filter-drier.

Loading...

Loading...