OM 750 Page 29 of 32

SPACE CO

2

SENSOR FAILURE (OPTIONAL) ( )

The Space CO2 Sensor Failure fault will occur when the UVC detects

an open or a short condition from the Space CO

2

sensor.

Effect:

• CO2 Demand Controlled Ventilation function is disabled

• Fault is indicated

CHANGE FILTER INDICATION ( )

The Change Filter Indication will occur when the UVC calculates that

the total fan run time has exceeded the allowed number of hours since

the last filter change.

Effect:

• Fault is indicated

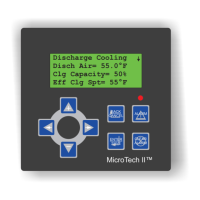

Troubleshooting Temperature Sensors

The UVC is configured to use passive positive temperature coefficient

(PTC) sensor whose resistance increases with increasing temperature.

The element has a reference resistance of 1035 ohms at 77°F (25°C).

Each element is calibrated according to the tables shown.

The following procedure can be used to troubleshoot a suspect sensor.

1. Disconnect both sensor leads from the UVC.

2. Take a temperature reading at the sensor location.

3.

Use the temperature reading from Step 2 to determine the expected

sensor resistance from the Temperature versus Resistance Table 22.

4. Using an ohmmeter, measure the actual resistance across the two

sensor leads.

5. Compare the expected resistance to the actual resistance.

6. If the actual resistance value deviates substantially (more than

10%) from the expected resistance, replace the sensor.

Table 22. Temperature versus Resistance Table

O

F (

O

C)

Resistance

O

F (

O

C)

Resistance

in Ohms

O

in Ohms

-40 (-40) 613 113 (45) 1195

-31 (-35) 640 122 (50) 1237

-22 (-30) 668 131 (55) 1279

-13 (-25) 697 140 (60) 1323

-4 (-20) 727 149 (65) 1368

5 (-15) 758 158 (70) 1413

14 (-10) 789 167 (75) 1459

23 (-5) 822 176 (80) 1506

32 (0) 855 185 (85) 1554

41 (5) 889 194 (90) 1602

50 (10) 924 203 (95) 1652

59 (15) 960 212 (100) 1702

68 (20) 997 221 (105) 1753

77 (25) 1035 230 (110) 1804

86 (30) 1074 239 (115) 1856

95 (35) 1113 248 (120) 1908

104 (40) 1153

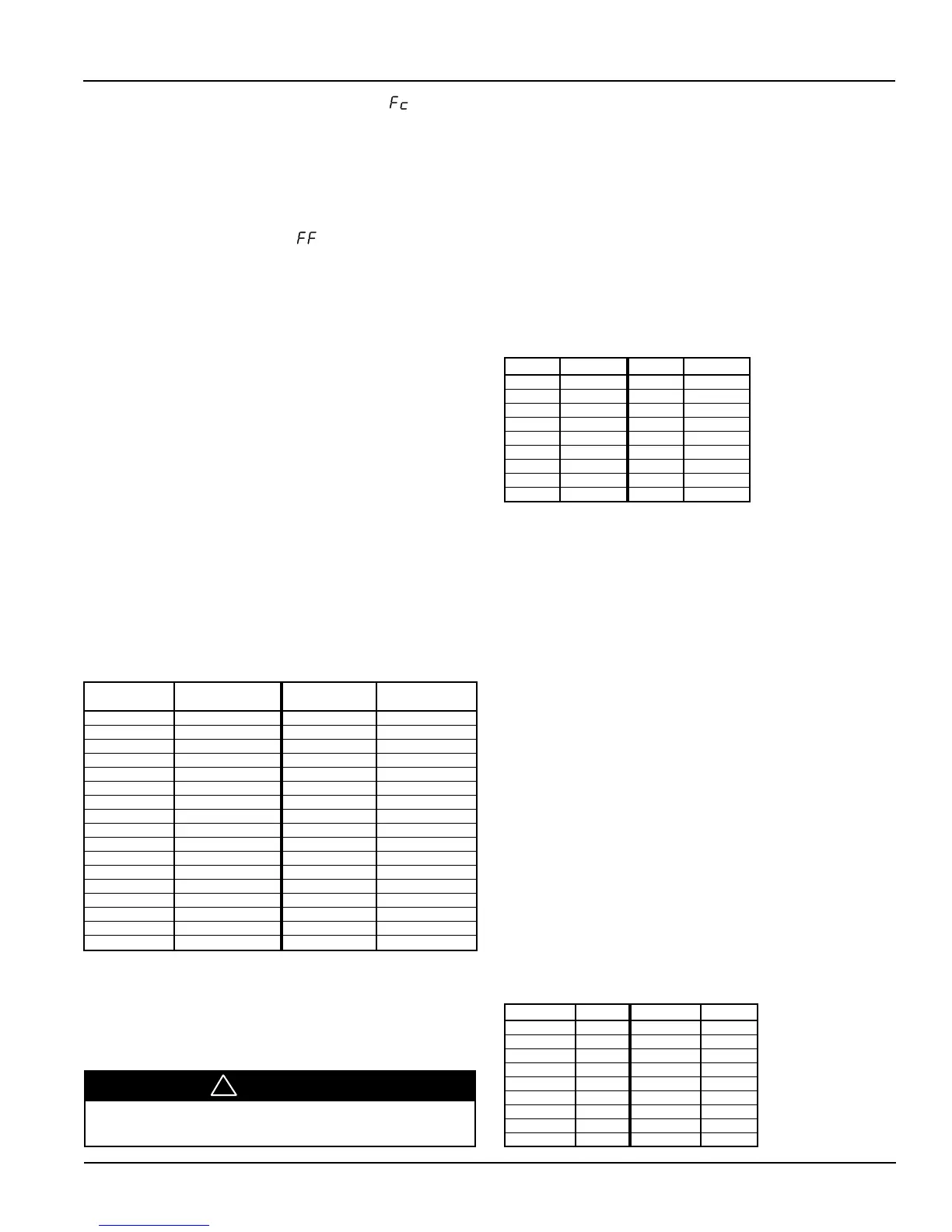

Troubleshooting Humidity Sensors

The UVC is configured to use 0-100% RH, 0-5 VDC, capacitive

humidity sensors. Each sensor is calibrated according to the table

shown.

/!\ Caution

The humidity sensor is not protected against reversed polarity. Check

carefully when connecting the device or damage will result.

CAUTION

!

The following procedure can be used to troubleshoot a suspect humidity

sensor.

1. Disconnect the sensor(s)’ output voltage lead from the UVC analog

input.

2. Take a humidity reading at the sensor location.

3. Use the humidity reading from Step 2 to determine the expected

sensor voltage from the Humidity versus Voltage Table 23.

4. Using a multi-meter, measure the actual voltage across the yellow

and white sensor leads.

5. Compare the expected voltage to the actual voltage.

6. If the actual voltage value deviates substantially (more than 10%)

from the expected voltage, replace the sensor.

Table 23. Humidity versus Voltage Table

RH (%) VDC (mV) RH (%) VDC (mV)

10 1330 55 2480

15 1475 60 2600

20 1610 65 2730

25 1740 70 2860

30 1870 75 2980

35 1995 80 3115

40 2120 85 3250

45 2235 90 3390

50 2360 95 3530

Troubleshooting Carbon Dioxide (CO

2

)

Sensors

The UVC is configured to use 0-2000 PPM, 0-10 VDC, single beam

absorption infrared gas sensor. Each sensor is calibrated according to

the table shown.

The following procedure can be used to troubleshoot a suspect sensor.

1. Disconnect the sensor(s)’ output voltage lead from the UVC analog

input.

2. Take a CO

2

reading at the sensor location.

3. Use the CO

2 reading from Step 2 to determine the expected sensor

voltage from the CO

2

versus Voltage Table 24.

4. Using a multi-meter, measure the actual voltage across the lead

removed from xAI-3 and ground.

5. Compare the expected voltage to the actual voltage.

6. If the actual voltage value deviates substantially (more than 10%)

from the expected voltage, replace the sensor.

In the unlikely event that the CO

2

sensor requires calibration, consult

the factory for information on obtaining calibration equipment and

instructions.

Table 24. CO

2

versus Voltage Table

CO

2

(PPM) VDC (V) CO

2

(PPM) VDC (V)

300 1.5 1200 6.0

400 2.0 1300 6.5

500 2.5 1400 7.0

600 3.0 1500 7.5

700 3.5 1600 8.0

800 4.0 1700 8.5

900 4.5 1800 9.0

1000 5.0 1900 9.5

1100 5.5 2000 10.0

DIAGNOSTICS AND SERVICE (continued)

Loading...

Loading...