Checking for leaks and general condi-

tion – assemblies

X

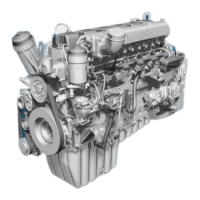

Carry out a visual inspection of the engine

for signs

of leaks. Slight dampness around

sealed joints can be ignored.

!

More severe leaks, where there is con-

stant oil loss, must be rectified immedi-

ately.

Lines, hoses and sensor cables –

checking for

leaks and general condi-

tion

X

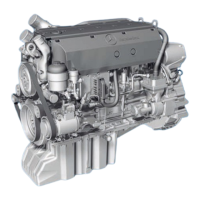

Carry out a visual check for leaks from lines

and hoses.

At the same time, check that all

lines and hoses are undamaged, are routed

so they do not chafe and are secured cor-

rectly.

X

Check the intake pipe between the air filter

and the engine for leaks and check the con-

dition.

X

Check the intake pipe and bellows from the

air filter as well as the charge-air cooler for

the engine for damage and for leaks at con-

nection points.

X

Check the air compressor intake pipe and

crankcase ventilation for damage and leaks

at connection points.

X

Check all hose clamps for correct seating.

Retighten or replace loose hose clamps.

X

Replace porous, leaking or damaged lines

and bellows.

G

WARNING

The engine becomes very hot while it is run-

ning

and

remains so for some time after it has

stopped. It will cause burns if touched.

Before starting any work on the engine, allow

all engine parts to cool down, or wear suitable

gloves and items of clothing to protect your-

self from being burned on hot engine compo-

nents.

G

WARNING

There is a danger of limbs being caught, pulled

in

and

thereby crushed or severed by rotating

engine parts. Therefore you should:

R

keep a safe distance between yourself and

rotating engine parts, including when the

engine is being started.

R

wait until all engine parts have stopped

moving before carrying out any work on the

engine.

R

wear work clothing which is properly fas-

tened and close-fitting. Wear a hair net if

necessary. Remove jewellery such as

watches and necklaces.

Work schedules

77

Notes on maintenance

Z

Loading...

Loading...