Engine cooling

Cooling and lubrication

41

Introduction of the New V12 Biturbo Engine, M 279 AMG

b

In order to guarantee the maximum engine power,

the engine and turbochargers must be properly

cooled.

The engine oil cooler (oil/air heat exchanger) is

located in the center

behind the front spoiler. Air

ducting provides optimum air flow and cooling

output. The warm waste air flows through an

opening in the underfloor paneling directly into the

atmosphere.

An additional engine oil cooler with fan is installed

in the righ

t front wheel arch.

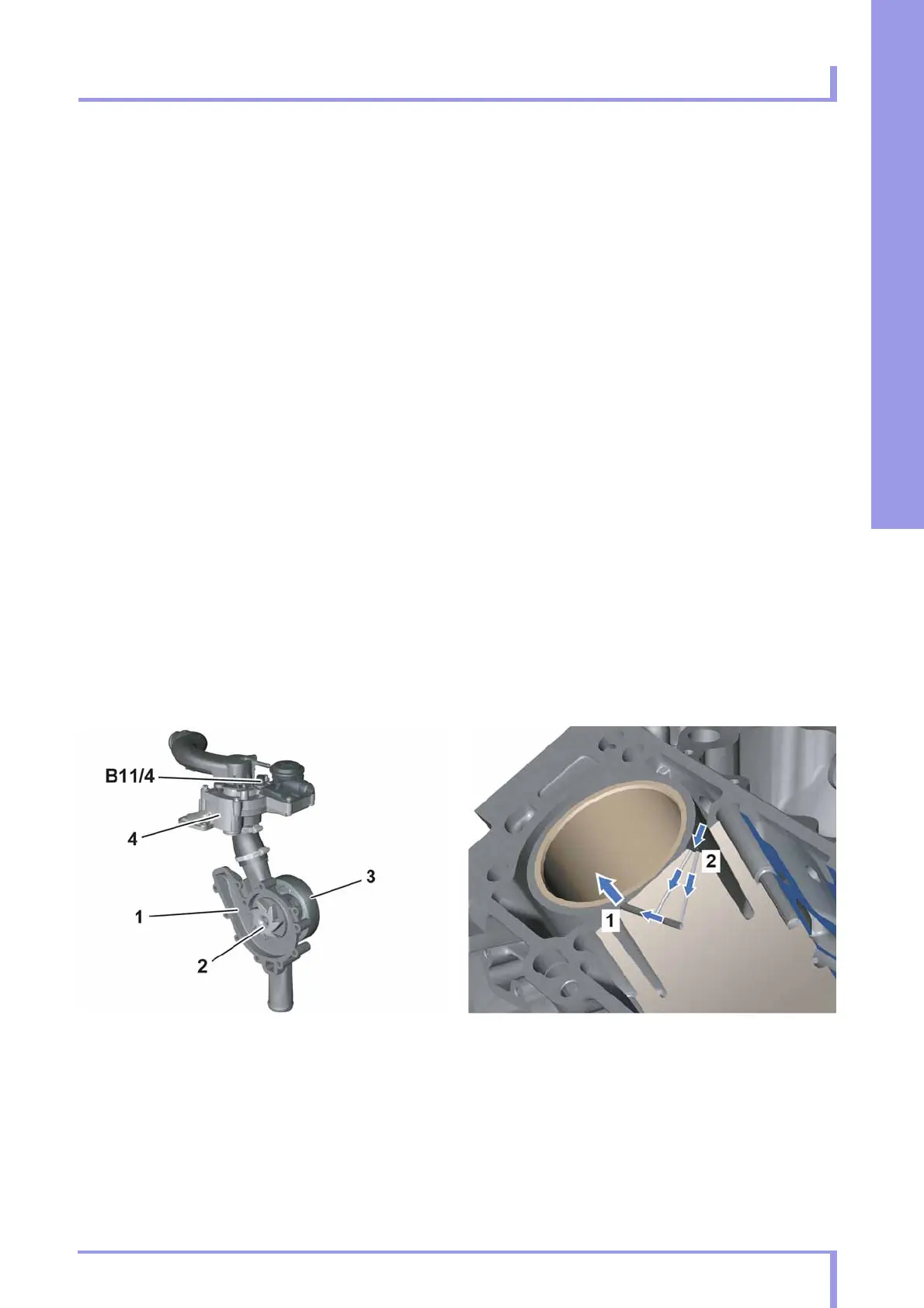

The interbore bridges between the cylinders in the

crankcase

have three bores for cooling: two feed

bores that

supply coolant to the bridge, and one

drain bore. The coolant flows out of the bridge via

the bore in the cylinder head. Here there is one feed

bore for each interbore bridge.

Coolant temperature regulation

The coolant temperature is regulated by the ME-SFI

control unit on the basis of the following sensors

and signals:

• Coolant temperature sensor

• Charge air temperature sensor

• Pressure sensor downstream of throttle valve,

engine load

• Accelerator pedal sensor

• Crankshaft Hall sensor, engine speed

• Temperature sensor in ME-SFI control unit

• Front SAM control unit with fuse and relay

mo

dule, out

side air temperature

• Instrument cluster, vehicle speed

• Electronic Stability Program control unit, wheel

speed

• Fully integrated transmission control controller

unit, status of transmission oil temperature

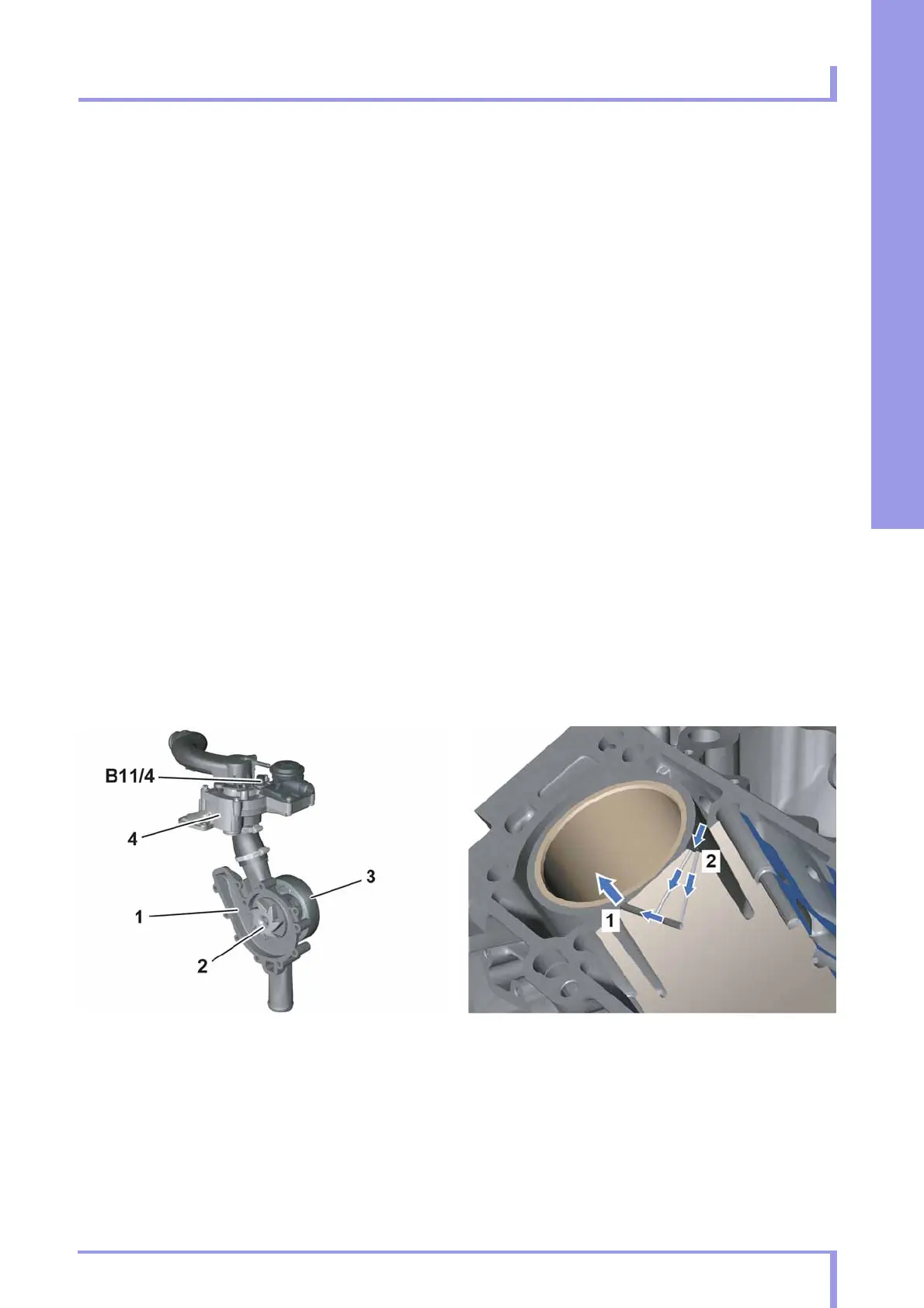

P20.10-2353-00 P20.00-2446-00

Coolant pump Interbore cooling

1Housing

2 Rotor

3 Belt pulley

4Coolant thermostat

B11/4 Coolant temperature sensor

1

Drain bore (to cylinder head)

2 Feed bore

– This printout will not be recorded by the update service. Status: 06 / 2012 –

Loading...

Loading...