MAINTENANCE

Page 1B-10 90-857138R1 MAY 2000

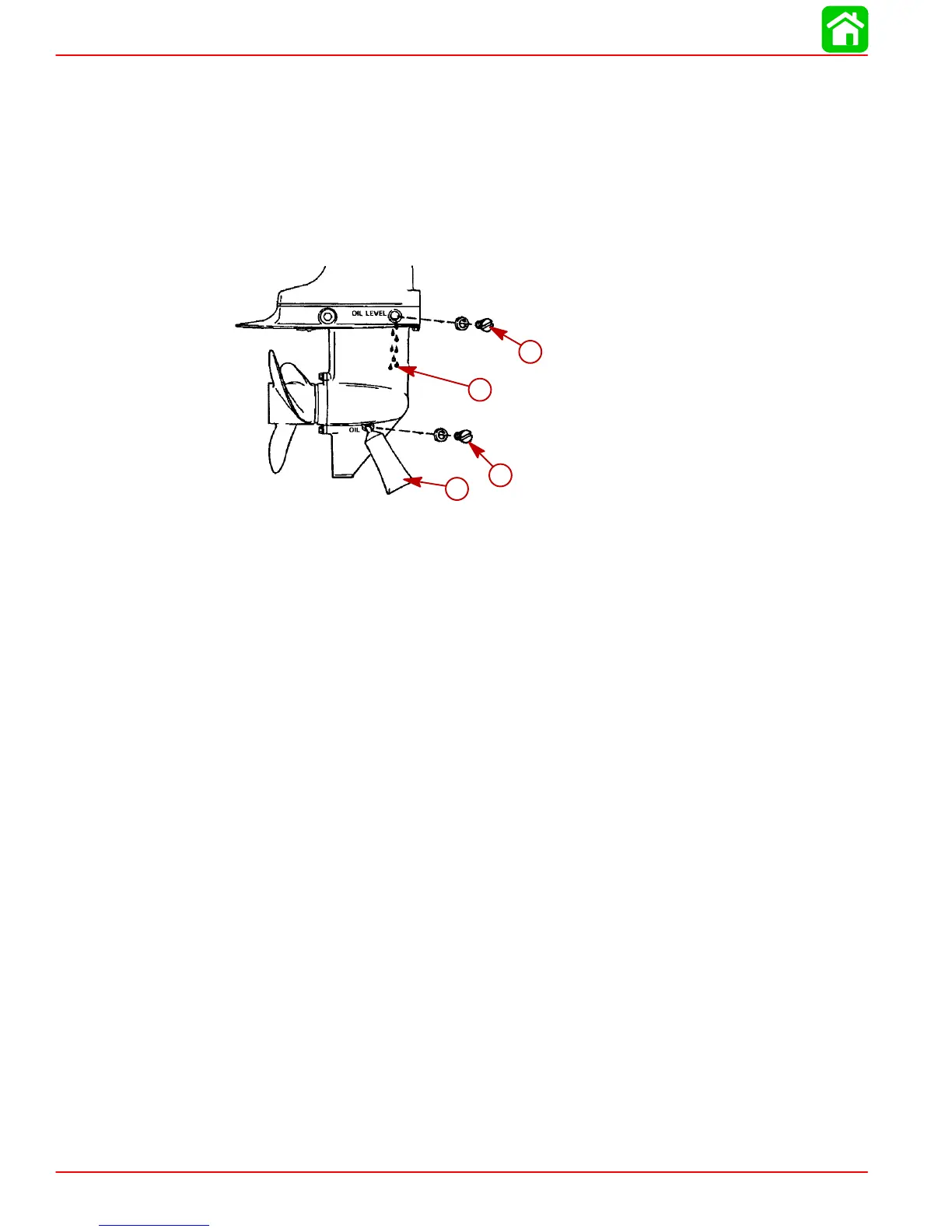

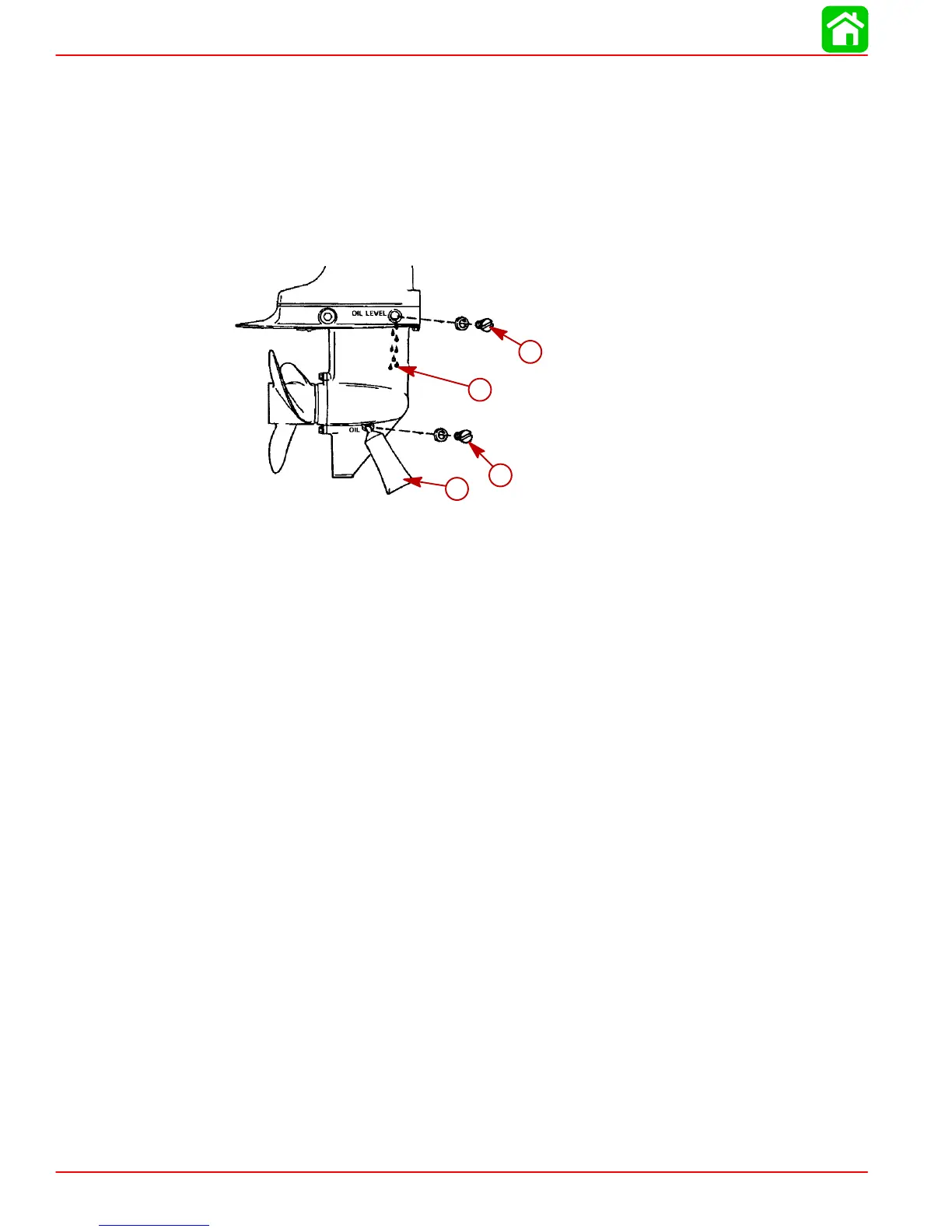

Checking Lubricant Level and Refilling Gear case

1. Place outboard in a vertical operating position.

2. Remove vent plug.

3. Place lubricant tube into the fill hole and add lubricant until it appears at the vent hole.

4. Stop adding lubricant. Install the vent plug and sealing washer before removing the lubri-

cant tube.

5. Remove lubricant tube and reinstall cleaned fill/drain plug and sealing washer.

a

c

d

b

a-Vent Plug/Sealing Washer

b-Lubricant Tube

c-Vent Hole

d-Fill/Drain Plug and Sealing Washer

Storage Preparations

Fuel System

IMPORTANT: Gasoline containing alcohol (ethanol or methanol) can cause a forma-

tion of acid during storage and can damage the fuel system. If the gasoline being

used contains alcohol, it is advisable to drain as much of the remaining gasoline as

possible from the fuel tank, remote fuel line, and engine fuel system.

Fill the fuel system (tank, hoses, fuel pumps, and fuel injection systems) with treated (stabi-

lized) fuel to help prevent formation of varnish and gum. Proceed with following instructions.

1. Portable Fuel Tank – Pour the required amount of Quicksilver Gasoline Stabilizer (follow

instructions on container) into fuel tank. Tip fuel tank back and forth to mix stabilizer with

the fuel.

2. Permanently Installed Fuel Tank – Pour the required amount of Quicksilver Gasoline

Stabilizer (follow instructions on container) into a separate container and mix with ap-

proximately one quart (one liter) of gasoline. Pour this mixture into fuel tank.

3. Place the outboard in water or connect flushing attachment for circulating cooling water.

Run the engine for ten minutes to allow treated fuel to fill the fuel system.

Protecting External Engine Components

1. Lubricate all outboard components listed in the Inspection and Maintenance Schedule.

2. Touch up any paint nicks.

3. Spray Quicksilver Corrosion Guard on external metal surfaces (except corrosion control

anodes).

Loading...

Loading...