3

A

FUEL PUMP & INTREGAL FUEL TANK

90-857138R1 MAY 2000 Page 3A-1

FUEL SYSTEM

Section 3A - Fuel Pump & Integral Fuel Tank

Table of Contents

Specifications 3A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quicksilver Lubricants and Service Aids 3A-1. . . . . .

Fuel Pump 3A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump Removal and Installation 3A-4. . . . . . . . .

Fuel Pump Disassembly 3A-5. . . . . . . . . . . . . . . . . . .

Fuel Pump Reassembly 3A-7. . . . . . . . . . . . . . . . . . . .

Integral Fuel Tank (4 HP Models Only) 3A-9. . . . . . .

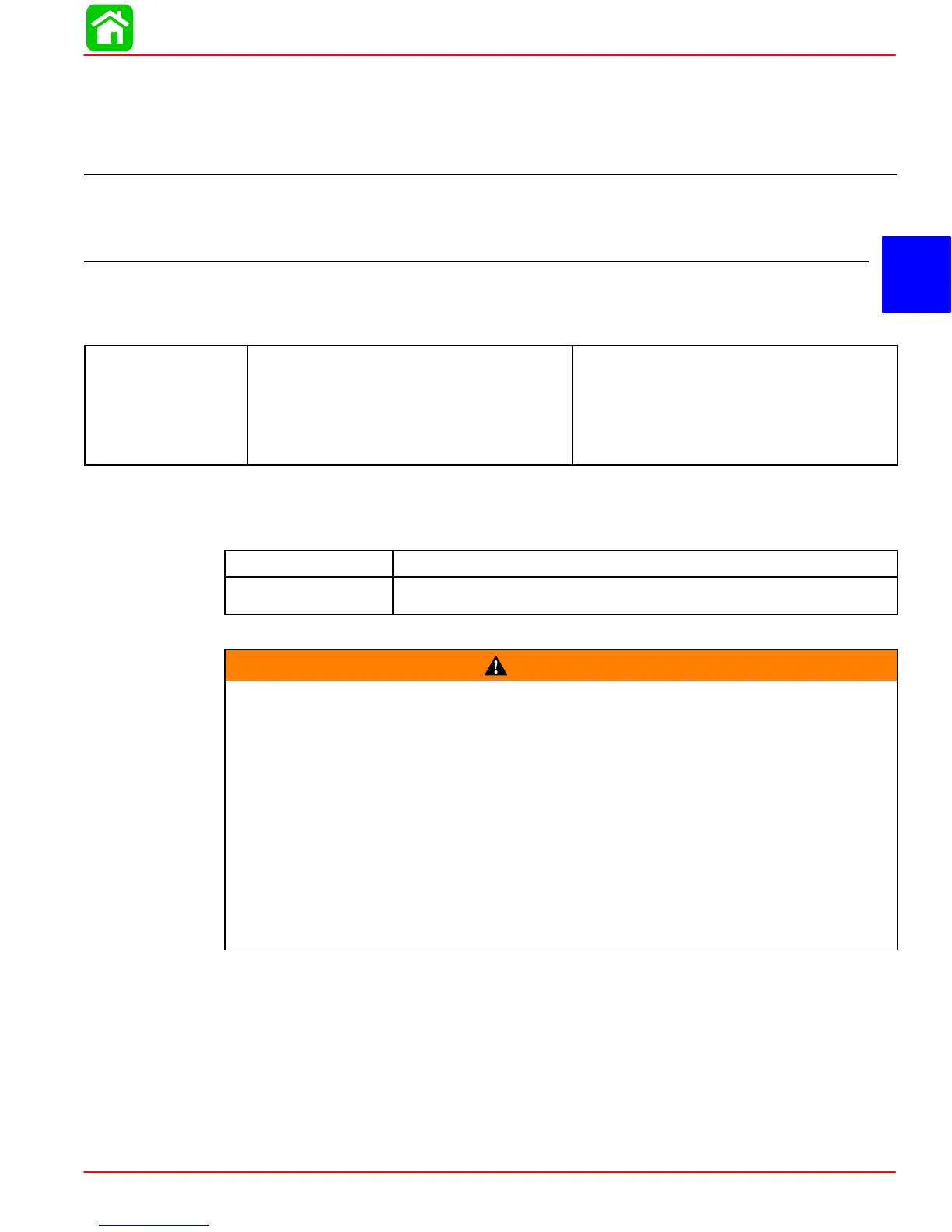

Specifications

FUEL

SYSTEM

Fuel Pump Type

Fuel Pump:

Pressure

Plunger Stroke

Diaphragm Stroke

Fuel Tank Capacity

External (Plunger/Diaphragm)

2.5 - 5.0 psi (17 - 35 kPa)

0.059 in. (1.5 mm)

0.059 in. (1.5 mm)

3.2 US Gallons

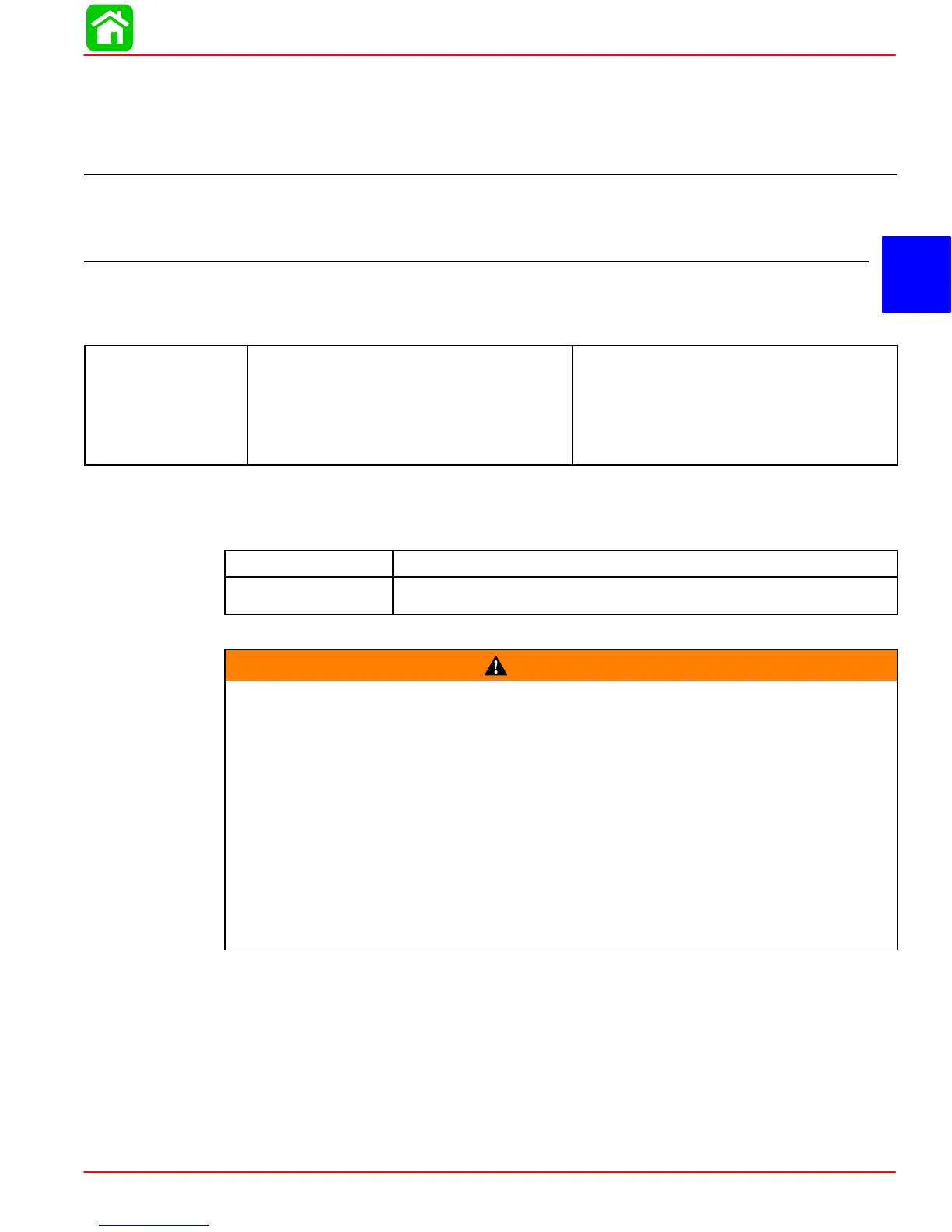

Quicksilver Lubricants and Service Aids

Part No. Description

92-828000A12 4-Cycle Outboard Oil

WARNING

FIRE AND EXPLOSION HAZARD. Observe fire prevention rules, particularly NO

SMOKING. Before servicing any part of the fuel system, disconnect electrical sys-

tem at the battery. Drain the fuel system completely. Use an approved container to

collect and store fuel. Wipe up any spillage immediately. Materials used to contain

spillage must be disposed of in an approved receptacle. Any fuel system service

must be performed in a well ventilated area

.

FUEL LEAKAGE FROM ANY PART OF THE FUEL SYSTEM CAN BE A FIRE AND EX-

PLOSION HAZARD WHICH CAN CAUSE SERIOUS BODILY INJURY OR DEATH.

Careful periodic inspection of the entire fuel system is mandatory, particularly after

engine storage. All fuel components, including fuel tanks, whether plastic, metal,

or fiberglass, fuel lines, primer bulbs, fittings, swelling, and must be inspected for

corrosion. Any sign of leakage or deterioration necessitates replacement before

further engine operation.

Loading...

Loading...