6 BC 71 en 7

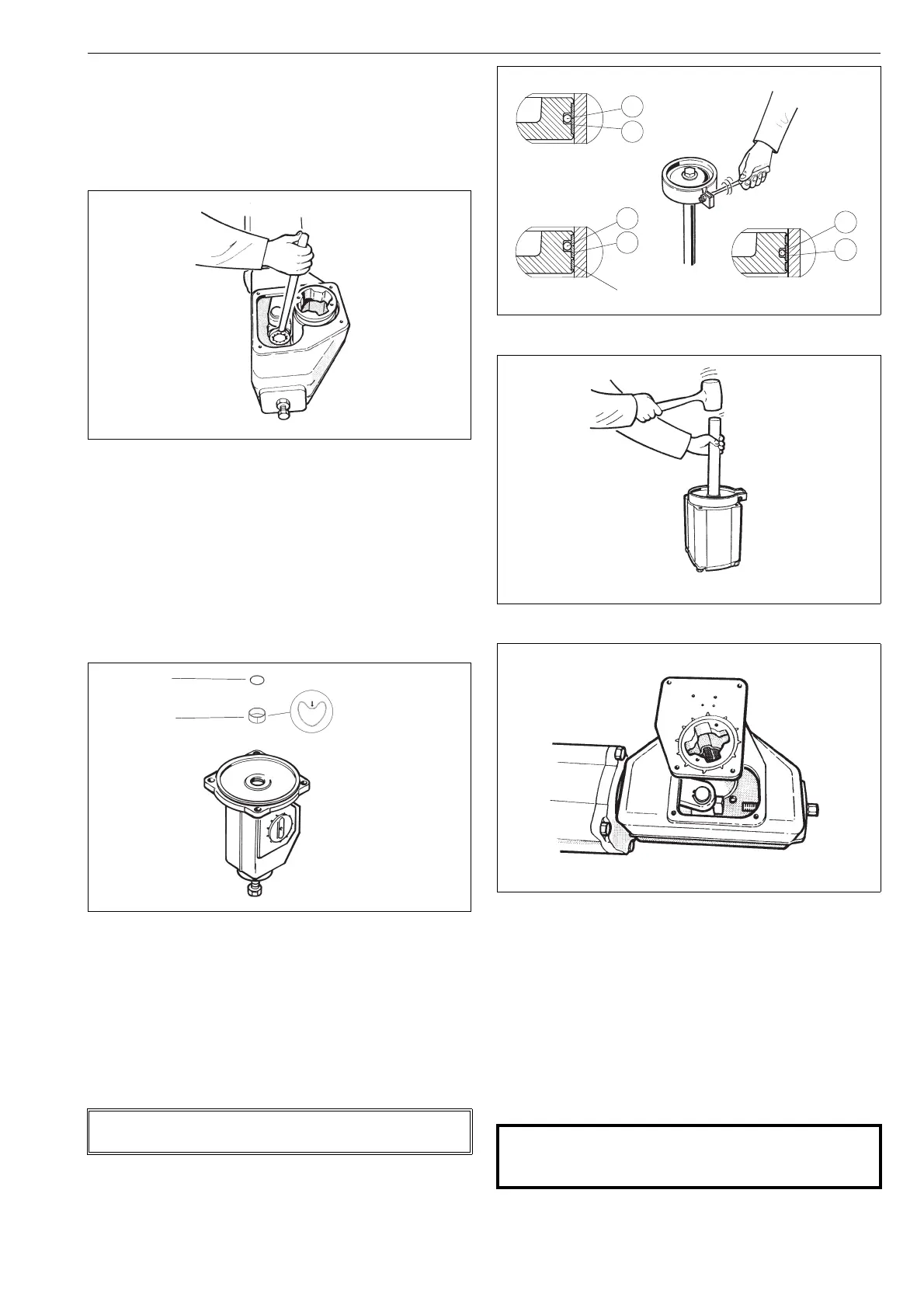

Loosen the fastening screw (29) of the bearing unit

and the fastening screws of the cylinder (31) from

the cylinder base (6). Should the piston turn with the

screw (29), remove the end of the cylinder (44) and

stop the turning with the piston fastening screw (28).

See Figure 8.

Remove the cylinder and the piston, including the

rod.

Remove the old seals and the O-ring (24, 18, 19).

Remove the O-ring (16) and the bearing (22). Clean

the seal space.

Lubricate the seal space and the new O-ring with

Unisilikon L250L or equal silicone grease. Install the

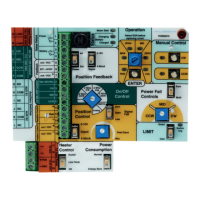

new bearing and O-ring. See Figure 9.

Clean the piston seal groove and lubricate with a

thin layer of Cortec VCI 369.

Place the O-ring (18) under the piston seals.

Locate the seals (24) around the piston so that the

ends of the strips come on opposite sides. Tighten

the strips with the tie ring as shown in Figure 10. The

strips marked with an asterisk (*) may be cut 1.5-

3 mm shorter to facilitate assembly.

Knock or press the piston through the tie ring with a

press, Fig. 11.

Mount the O-ring (19) and the cylinder and piston.

Note the location of the air inlet: use the air inlet of

the cylinder base as a guide. Tighten the screws (31).

See Table 1 for torques.

Apply locking sealant e.g. Loctite 225 to the threads

of the fastening screw (29) of the bearing unit and

tighten it. See Table 1 for torque.

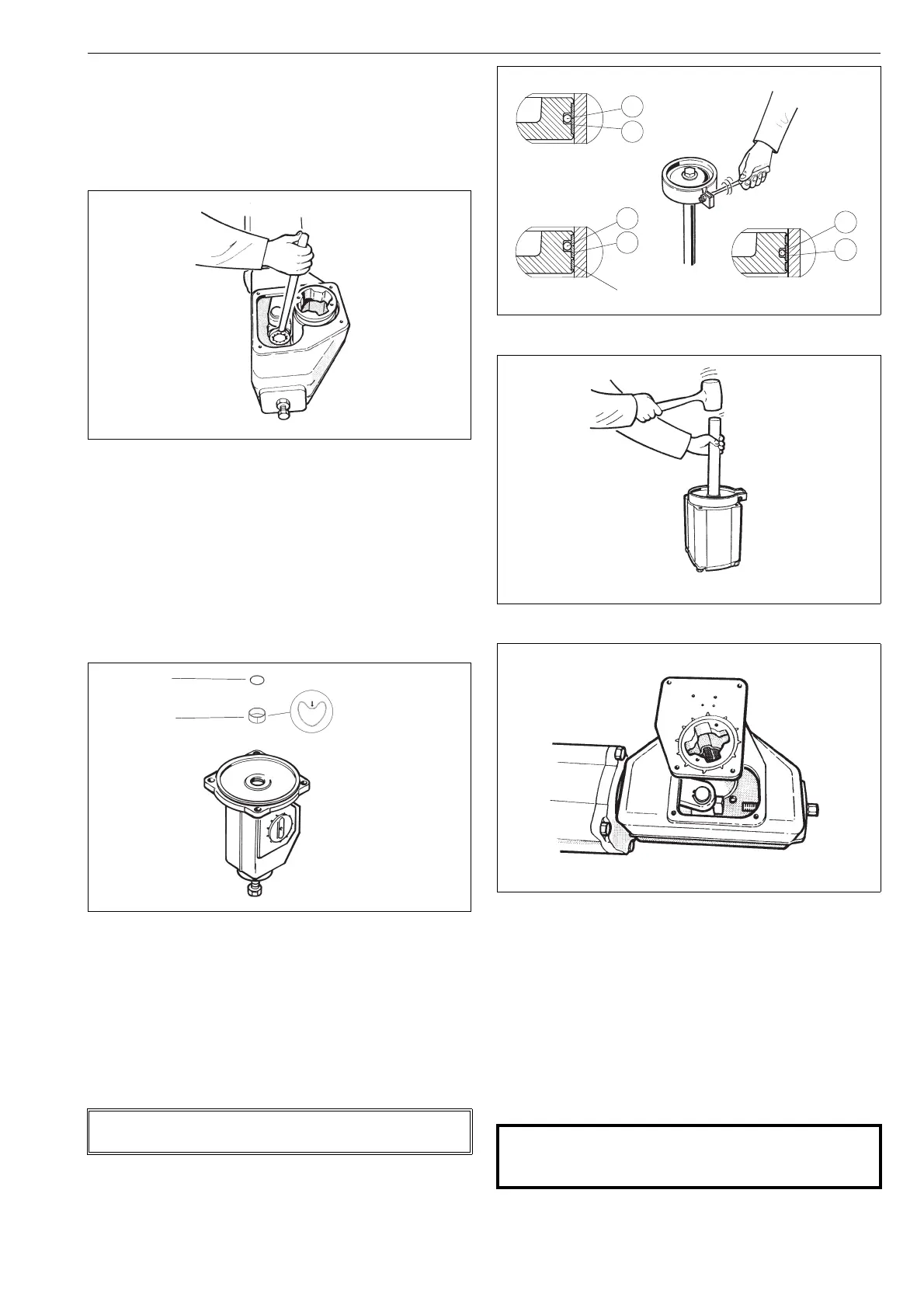

Fasten the housing cover temporarily so that the link-

age bearings (3) function, but the linkage is still visible,

Fig. 12. Note the grounding rings (3A, 4A).

Fig. 8 Opening the fastening screw of the actuator bear-

ing unit

Fig. 9 Mounting the piston rod bearing and seal

NOTE:

The inside surface of the cylinder must be free of any grease!

Press the bearing

strip like this to

facilitate installation

16

22

Fig. 10 Tightening piston seals with a tie ring

Fig. 11 Placing the piston in the cylinder

Fig. 12 Mounting the cover on the housing

CAUTION:

Keep your fingers, tools or other items out of the hous-

ing while operating the actuator with the cover open!

Loading...

Loading...