6 BC 71 en 9

4.4 Maintenance of a B1CM actuator

The structure of the B1CM actuator is the same, except for

the manual operation lever connected with lever arm (3).

See the exploded view, Section 8.

Maintenance as in Sections 4.1 and 4.2.

4.5 Maintenance of B1C502-752 actuators

The structure of the B1C502-752 actuators is in principle the

same as a normal B1C actuator. In order to ensure a high

operating torque, the equipment is fitted with two cylin-

ders connected to the secondary shaft.

For maintenance see Sections 4.1 and 4.2.

5 MALFUNCTIONS

Table 2 lists malfunctions that might occur after prolonged

use.

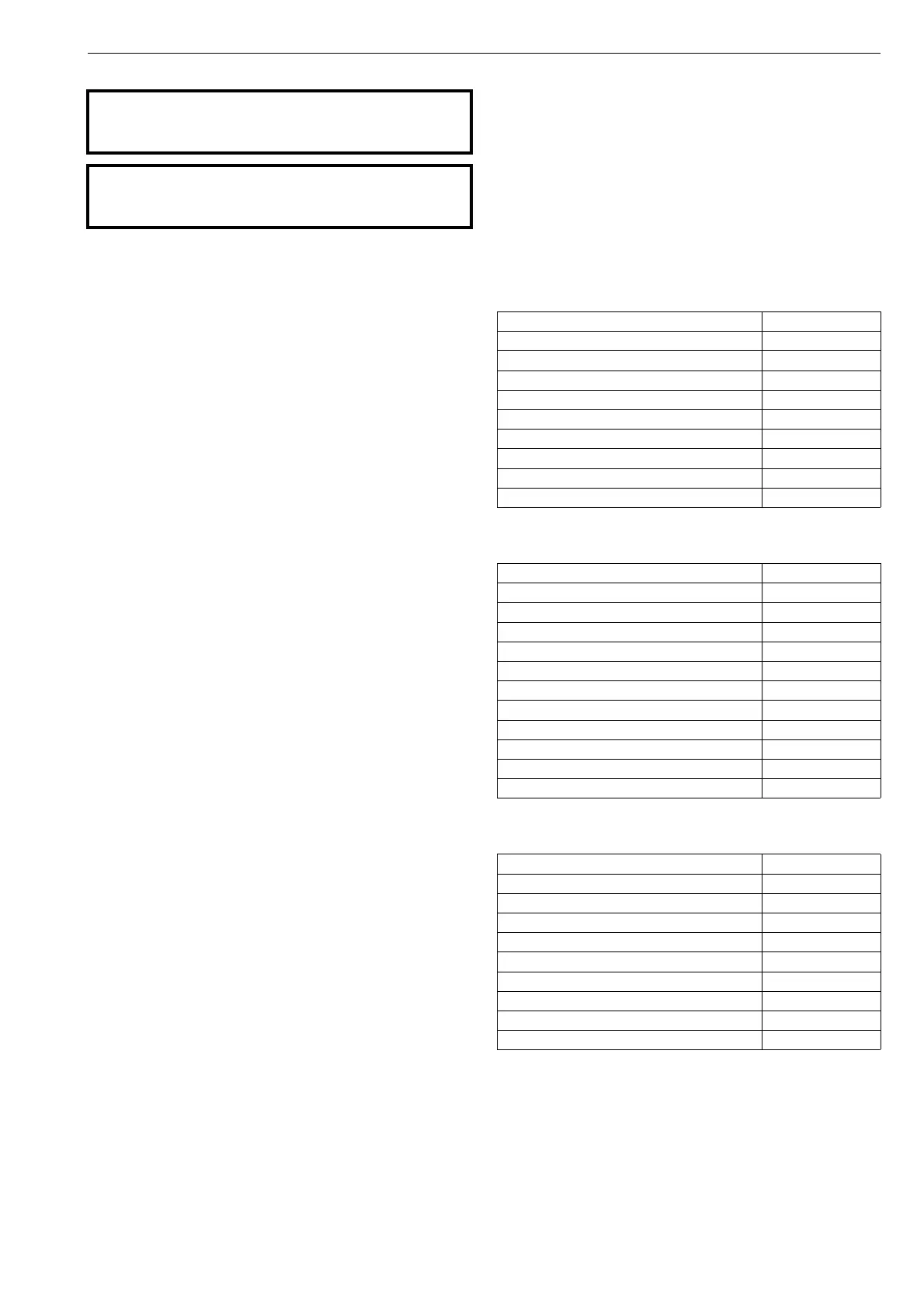

6 TOOLS

For maintenance of the actuator, you will need a few special

tools in addition to the usual ones. The following can be

ordered from the manufacturer:

For actuator removal:

- Extractor (Table 3)

For piston seal installation:

- Tie ring (Table 4)

For cylinder base removal:

- Lock nut key (Table 5)

Table 3 Extractor tools

Table 4 Mounting Collars

Table 5 Shaft nut tools

CAUTION:

Don’t use the lever in the torsion arm for manual oper-

ation when the actuator is pressurized!

CAUTION:

Don’t leave the lever in the torsion arm after manual

operation!

Actuator size Tool ID.

BC/BJ 6 303821

BC 8-11 / BJ 8-10 8546-1

BC 12-17 / BJ 12-16 8546-2

BC/BJ 20 8546-3

BC/BJ 25 8546-4

BC/BJ 32 8546-5

BC 40 / BJ 322 8546-6

BC 50 8546-7

BC 502 8546-8

Actuator size Tool ID.

BC 6-8 7814-1

BC 9-10 7814-2

BC 11-12 / BJ 8 7814-3

BC 13-16 / BJ 10 7814-4

BC 17-20 / BJ 12 7814-5

BC 25 / BJ 16 7814-6

BC 32 / BJ 20 7814-7

BC 40 / BJ 25 7814-8

BC 50, 502 / BJ 32, 322 7814-9

BC 60, 602 cylinder Ø 600 7814-10

BC 75, 752 7814-11

Actuator size Tool ID.

BC/BJ 8 260155

BC 10-11 / BJ 10 260156

BC 12-13 / BJ 12 260157

BC 16-17 / BJ 16 260172

BC/BJ 20 260196

BC/BJ 25 260195

BC 32 / BJ 32, 322 261153

BC 40 261154

BC 50, 502 261155

Loading...

Loading...