6 6 BC 71 en

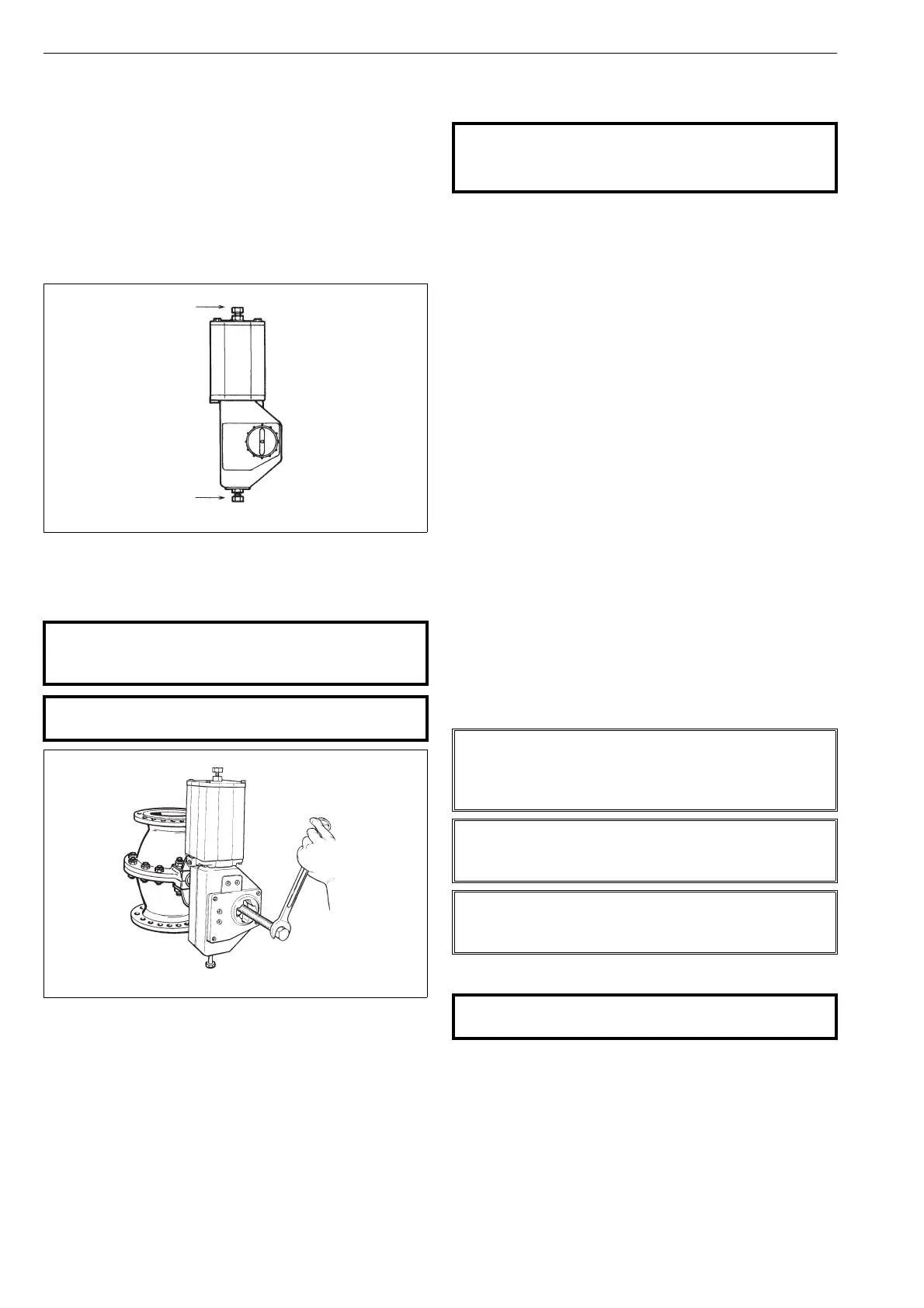

There are two adjustable stop screws in the actuator; these

stop the movement of the secondary shaft in the extreme

positions. The actuator generates a torque of approxi-

mately 1.3 times the nominal torque when the piston is at

the upper end of the cylinder, see also Fig. 3. For some

valves, e.g. butterfly valve, the closing torque and position

is accurate. The stop screw at the cylinder end has to be

adjusted according to right instructions, see separate valve

specific instructions for more detailed information. An O-

ring (33A) is used for sealing the stop screw in the cylinder

end. See also the instructions of the valve.

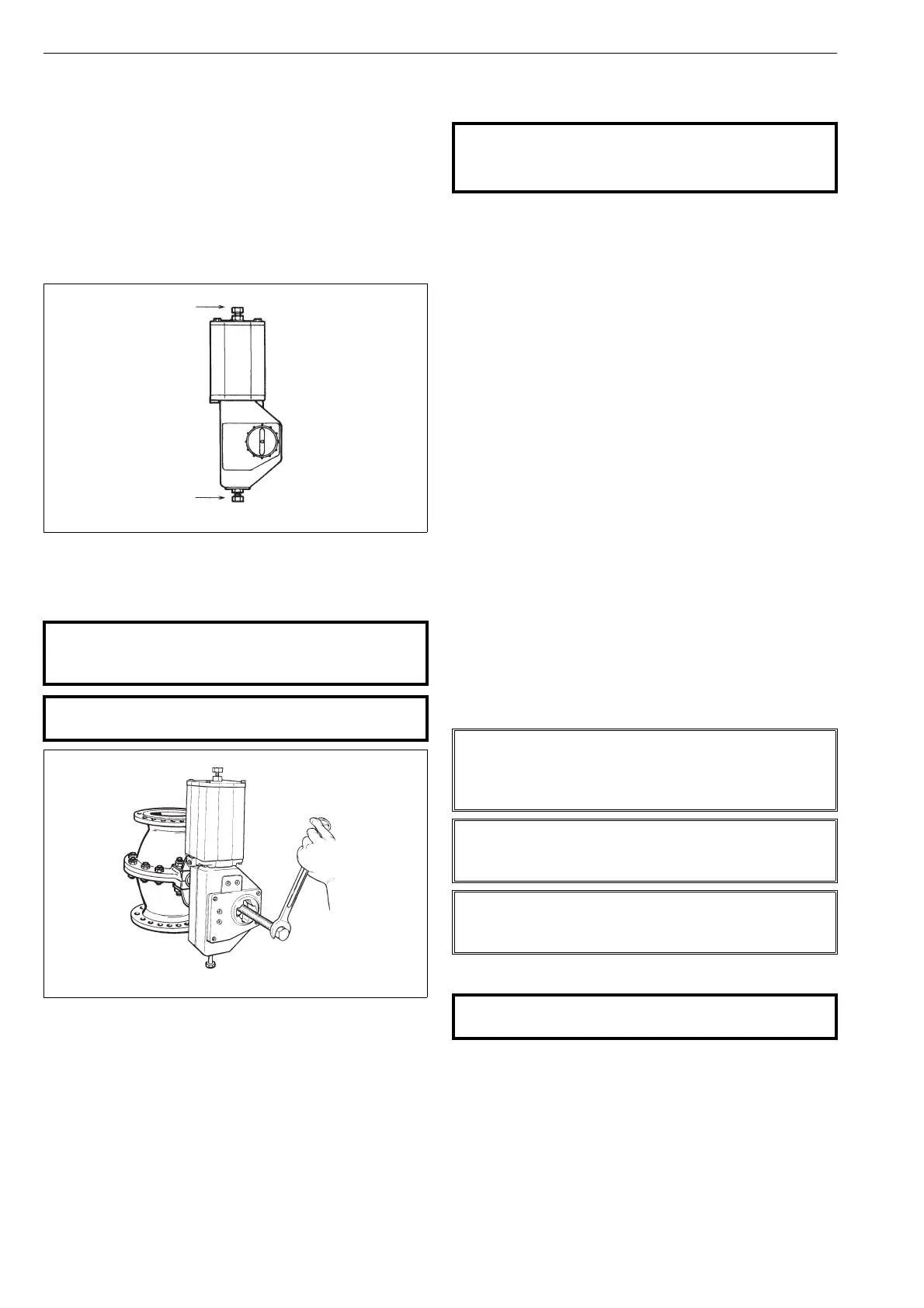

3.3 Demounting the actuator from the

valve

The actuator must be depressurized and the supply air

pipes disconnected. Unscrew the actuator-side screws of

the bracket and pull the actuator off the valve shaft. This is

best done using a specific extractor, see Fig. 7 and Section

6. Note the mutual positioning of the valve and the actua-

tor to ensure correct functioning after reassembly.

4 MAINTENANCE

4.1 Maintenance general

Although Metso’s Neles actuators are designed to work

under severe conditions, proper preventative maintenance

can significantly help to prevent unplanned downtime and

in real terms reduce the total cost of ownership. Metso rec-

ommends inspecting the actuators at least every five (5)

years.

The inspection and maintenance interval depends on the

actual application and process condition. The inspection

and maintenance intervals can be specified together with

your local Metso experts.

During this periodic inspection the parts detailed in the

Spare Part Set should be replaced. Time in storage should

be included in the inspection interval.

Maintenance can be performed as presented below. If

maintenance assistance is required, please contact your

local Metso office.

The part numbers in the text refer to the exploded view and

to the parts list in Section 8, unless otherwise stated.

Under severely corrosive conditions, the linkage system

inside the housing should be lubricated at six month inter-

vals. Use Cortec VCI 369 anti-corrosive agent or the equiva-

lent. The housing may also be half filled with semi-fluid

water-repellant grease (e.g. Mobilux EP2) while the piston

rod is in the lower position.

If you remove the stop screw, adjust the limits after

lubrication or grease filling!

4.2 Replacement of piston seals

Replacement of all seals and soft bearings is recommended

when the actuator has been disassembled for maintenance.

Operate the actuator so that the piston goes to the

outermost end of the cylinder. Release the pressure

from the cylinder.

Remove the cover of the housing (2).

Fig. 6 The stop screws in the open and closed positions

CAUTION:

Take the weight of the actuator or valve combination

into account when handling it!

CAUTION:

Beware of the cutting movement of the valve!

Fig. 7 Removing the actuator with the extractor

stop screw for

closed position

stop screw for

open position

CAUTION:

Observe the safety precautions mentioned in Section

1.6 before maintenance!

NOTE:

In order to ensure safe and effective operation, always use

original spare parts to make sure that the actuator func-

tions as intended.

NOTE:

When sending goods to the manufacturer for repair, do

not disassemble them.

NOTE:

For safety reasons, replace bolting if the threads are dam-

aged, have been heated, stretched or corroded.

CAUTION:

Don’t dismantle a pressurized actuator!

Loading...

Loading...