1-1

Error no. H0001

1Error list

1 Error list

(1) Error No.

When an error occurs, ERROR LED at the front of the controller will turn on or blink.

The four-digit error number (number except the one character of the head.) is displayed on LCD of T/B.

Example: In the case of C0010, display the display and the error message for "0010."

In addition, the alarm rings at 0.5-second intervals while an error is occurring. When resetting the power supply, if

the interval between turn-on and turn-off of a controller is too short, the alarm rings at 0.1-second intervals.

The message, cause and measures to be taken are displayed in Table 1-1 for the error Nos. that may appear.

Also, a detailed message will be displayed on the Error History screen of the T/B, depending on the error No. of

the error occurred. Check by displaying the Error History screen after resetting the error.

If the error recurs even after the measures in the table are taken, contact your service provider.

(2) Cause and measures against the error

The details, cause and measures of the error number occurrence are shown in Table 1-1.

Note) The contents of the error caused with option products are written in the instruction manual of the option.

Refer to each instruction manual.

Table 1-1 : Error list

ERROR LED status Details

On Low-level error, or warning occurred.

Flashing High-level error occurred.

Off Normal operation.

Error No. Error cause and measures

H0001 Error message Fail safe error (SRVOFF)

Cause The system may be abnormal.

Measures Turn the power OFF and ON once. If it comes back, contact to your service provider.

H0002 Error message Fail safe error (STOP)

Cause The system may be abnormal.

Measures Turn the power OFF and ON once. If it comes back, contact to your service provider.

H0003 Error message The system is abnormal.

Cause The problem of the system is the cause.

Measures If it comes back, contact to your service provider.

H0004 * Error message CPU Watch dog error

Cause CPU was not normally treatable

Measures It is necessary to change some parts when not improvement. If it comes back, contact to your service

provider.

* The "CPU" part in each message varies according to the CPU in which an error is detected.

RCPU_main, CCPU_main, RCPU_sub, CCPU_sub, CPU_main, CPU_sub, FPGA, RCPU_PLD, CCPU_PLD

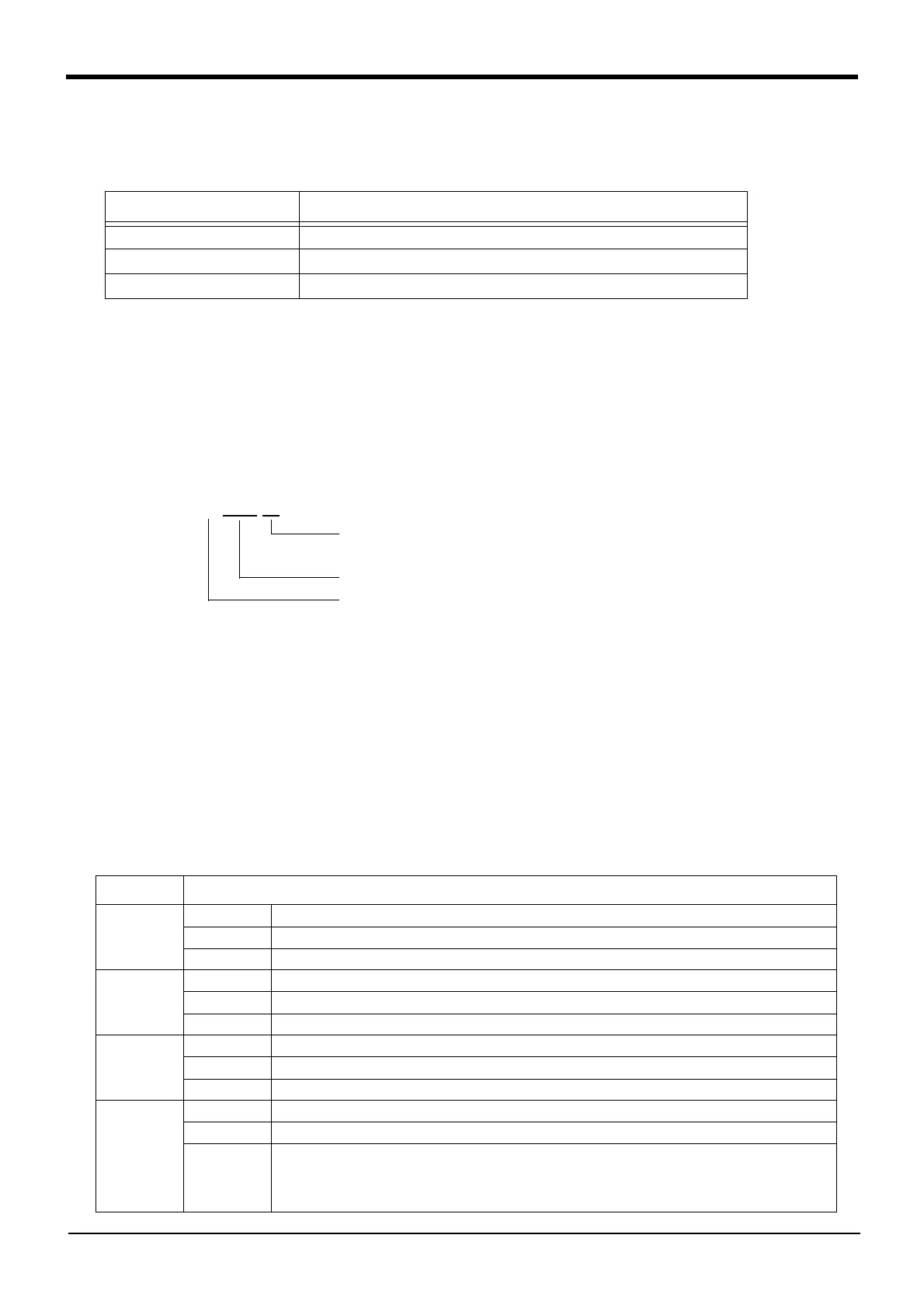

[Note] ・ The meaning of the error Nos. in Table 1-1 are shown below.

□ 0000

*

・An error marked with a * reset by turning the power OFF and ON.

Take the measures given.

・ The error type is indicated with a 4-digit number.

・ Three types of error classes are indicated.

H: High level error.................The servo turns OFF.

L: Low level error ..................The operation will stop.

C: Warning ................................The operation will continue.

・ The axis No. may be indicated at the last digit of the error No.

Example) H0931 No. 1 axis motor overcurrent.