GENERAL INFORMATION

TSB Revision

INTAKE AND EXHAUST

15-2

GENERAL INFORMATION

M1151000101041

The exhaust pipe is divided into three parts.

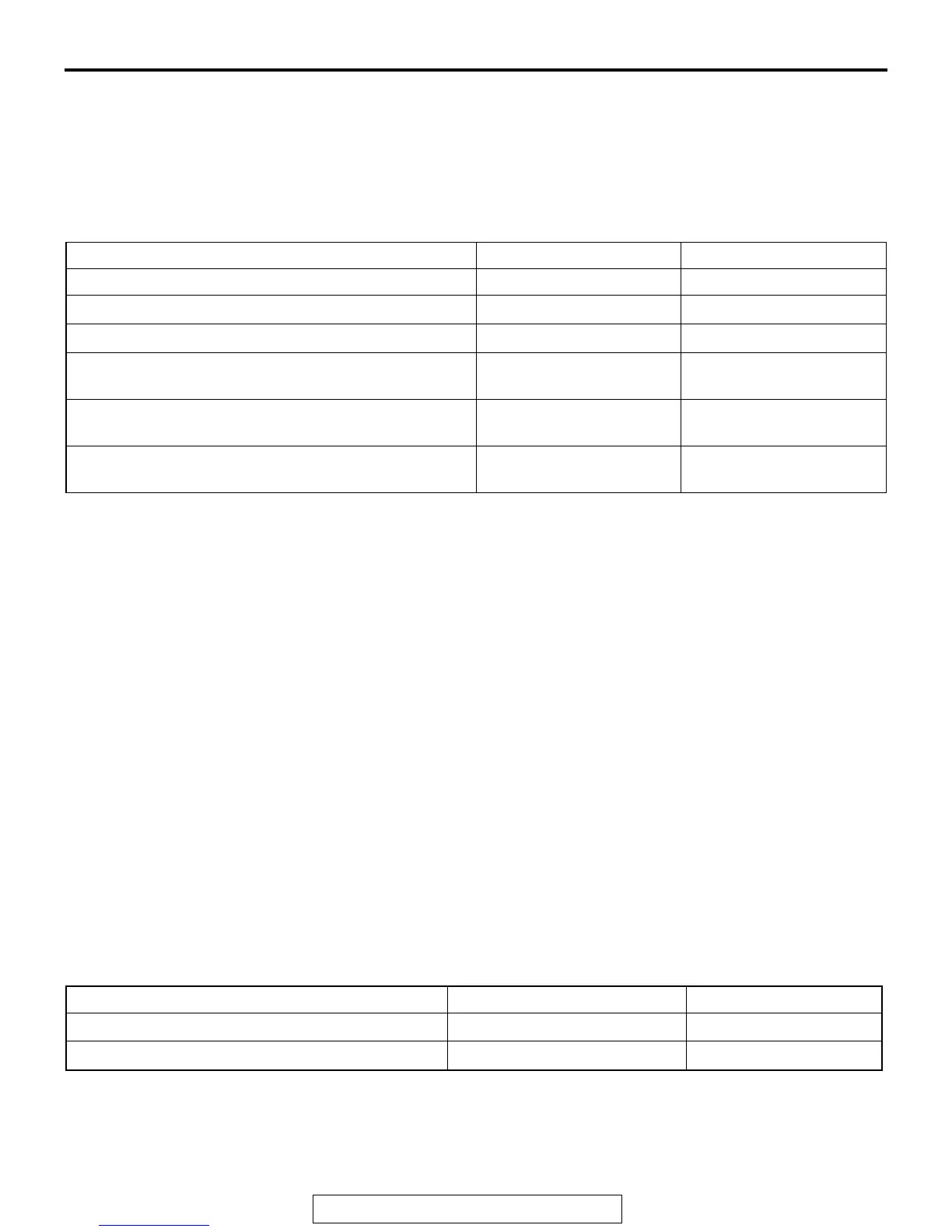

SERVICE SPECIFICATION

M1151000301335

ITEM STANDARD VALUE LIMIT

Manifold distortion of the installation surface mm (in) 0.15 (0.006) or less 0.20 (0.008)

Intake charge pressure kPa (psi) 85 − 159 (12.4 − 23.0)

−

Turbocharger waste gate actuator pressure kPa (psi) 98 − 102 (14.3 − 14.7)

−

No. 1 Turbocharger waste gate solenoid terminal

resistance [at 20

° C (68° F) ] Ω

29 − 35

−

No. 2 Turbocharger waste gate solenoid terminal

resistance [at 20

° C (68° F) ] Ω

29 − 35

−

Exhaust manifold distortion of the installation surface

mm (in)

−

0.70 (0.028)

INTAKE AND EXHAUST DIAGNOSIS

INTRODUCTION

M1151006900406

Intake leaks usually create driveability issues that

are not obviously related to the intake system.

Exhaust leaks or abnormal noise is caused by

cracks, gaskets and fittings, or by exhaust pipe or

muffler damage due to impacts during travel. The

exhaust leaks from these sections and causes the

exhaust noise to increase. There may be cases

when the system contacts the body and vibration

noise is generated.

TROUBLESHOOTING STRATEGY

M1151007000398

Use these steps to plan your diagnostic strategy. If

you follow them carefully, you will be sure that you

have exhausted most of the possible ways to find an

intake or exhaust system fault.

1. Gather information from the customer.

2. Verify that the condition described by the

customer exists.

3. Find the malfunction by following the Symptom

Chart.

4. Verify malfunction is eliminated.

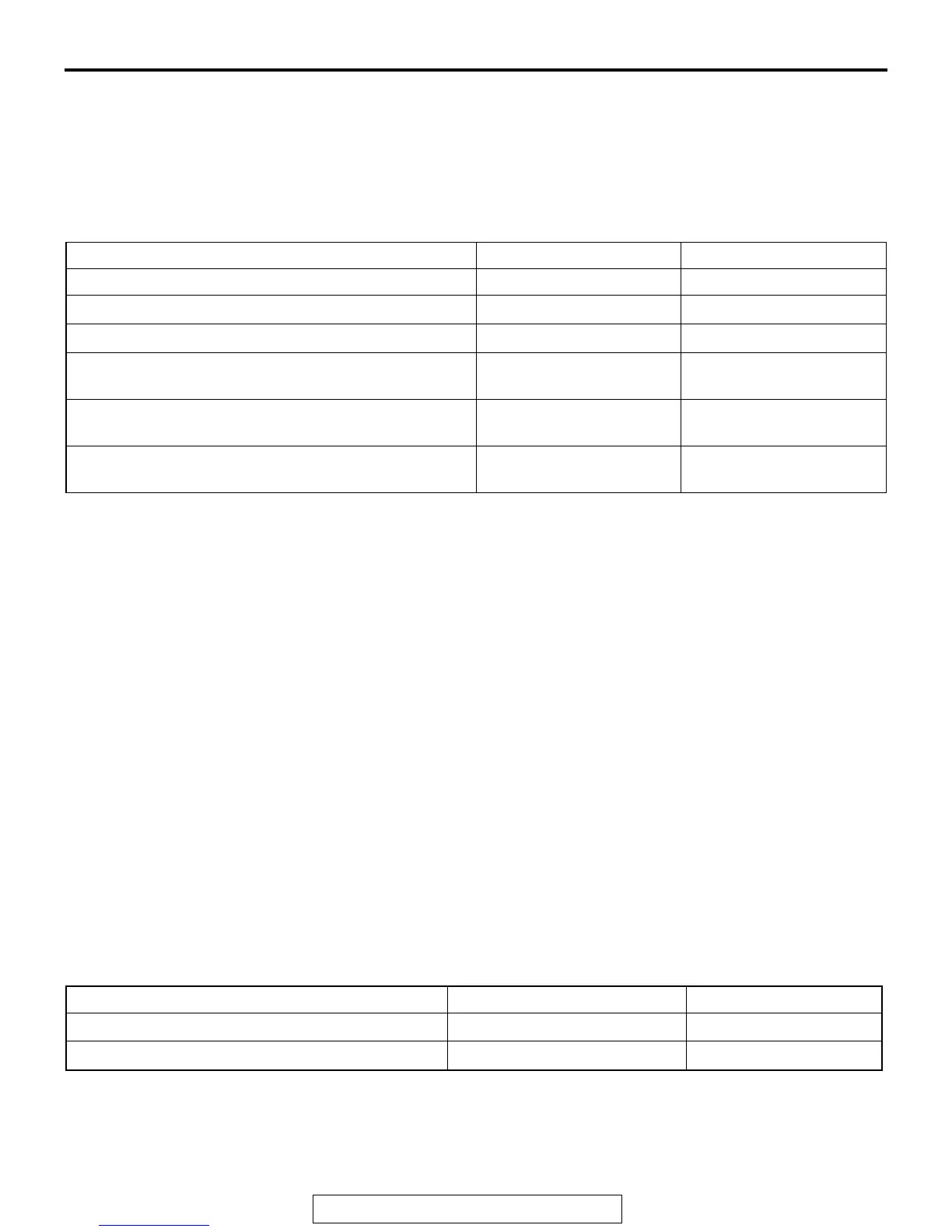

SYMPTOM CHART

M1151007100395

Symptom Inspection procedure Reference page

Exhaust Leakage 1

P.15-3

Abnormal Noise 2

P.15-3

Loading...

Loading...