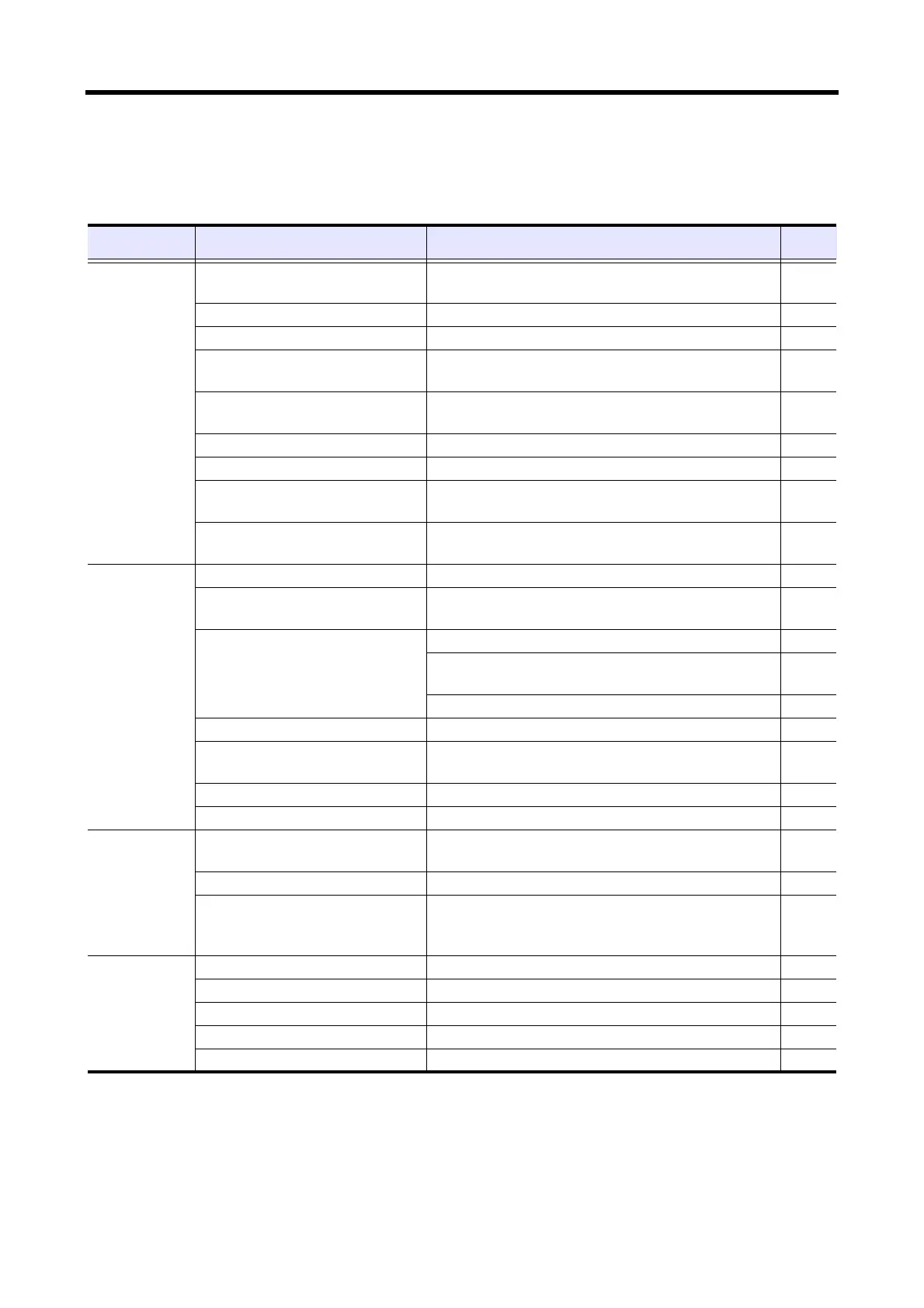

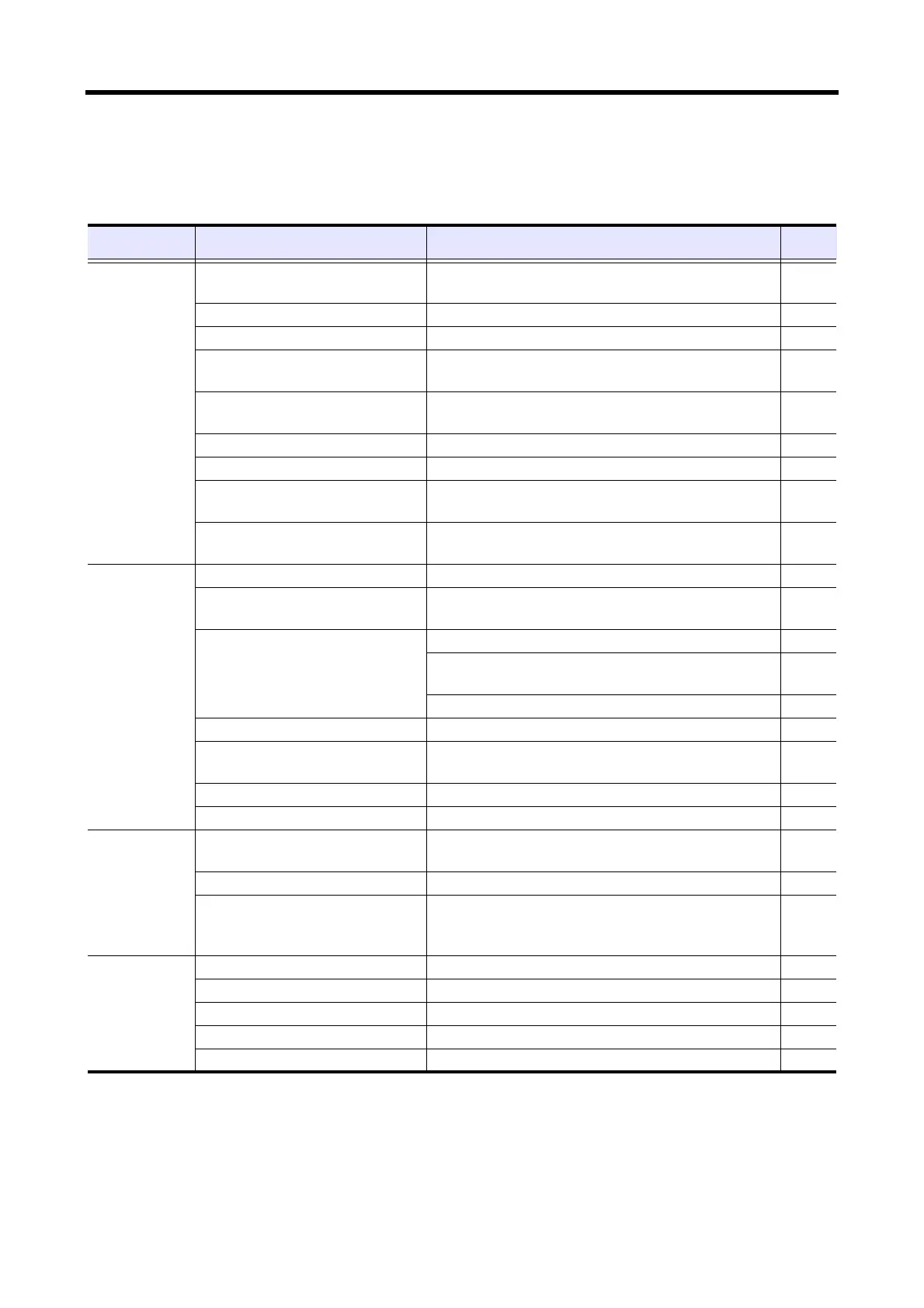

Chapter 5 PERIODIC MAINTENANCE CHART

5-3

Periodic Maintenance Chart for Engine in Regular Use

Table 5-1 Periodic maintenance chart for engine in regular use (1 / 5)

Service

interval

Service item Service contents Page

Every day

External

Inspect leakage and looseness of bolts and nuts.

Retighten bolts and nuts.

3-8

Fuel tank Inspect fuel level and drain water. 3-9

Fuel filters (wire-element) Clean inside of the filter by using handle. 3-8

Engine oil

Inspect oil level and add oil by using oil level

gage. Inspect level regulator operation.

3-9

Coolant

Inspect coolant level and add coolant by using

fluid level gage.

3-10

Air cleaner Inspect air cleaner indicator for element clog. 3-10

Air starter tank Inspect air pressure and drain water. 3-11

Operating condition

Check operating period, performance record,

sound, vibration and gage function.

3-13

Air cooler

Inspect water leakage from air cooler chamber

and drain water.

6-16

Every 500

service

hours

Fuel filters Drain water. 6-1

Fuel control linkage

Inspect ball joints, bolts and nuts for looseness

and smooth movement.

6-6

Engine oil

Inspect engine oil for mixing of fuel and water.

6-11

Analyze engine oil properties

(according to engine oil analysis service)

6-12

Change. 6-7

Oil filter and bypass oil filter Change. 6-7

Exhaust pipes and exhaust

muffler

Inspect and drain water. 6-16

Air starter compressor Drain water. 6-18

Zinc rod Inspect and change. 6-13

First 1500

service

hours

Valve clearance

Inspect and adjust (also inspect inside of rocker

chamber).

½

Camshafts and tappets Inspect. ½

Air cooler cover

Retighten air cooler cover mounting bolt (Also

after first 1500 service hours from gasket

replacement).

½

Every 1500

service

hours

Fuel filters Change. 6-3

Coolant Inspect LLC concentration. 6-14

Pre-cleaner Clean. 6-16

Air cleaner element Clean and inspect. 6-17

Air starter strainer Drain water and clean. 6-18

Loading...

Loading...