2200Q2JE-HO-KHM-N_2015.02.

Chapter 5 Maintenance and Inspection

Ammonia Semi-hermetic Motor with K-series Compressor 5.1 Precautions for Maintenance

5-5

5.3 Disassembly

5.3.1 Refrigerant Gas Recovery

Since the semi-hermetic motor is integrated with the compressor, the ammonia refrigerant inside must

be recovered before overhauling.

There are a few methods of recovering the refrigerant. For example, one method is to operate the

refrigerator, close the supply source valve, turn the gas into liquid, and recover the liquid at the receiver.

Another method is to use a refrigerant recovery machine to recover the liquid. As such, choose the

means that best meets your purpose and legal requirement.

Prepare a working flow sheet of the system beforehand. Prior to the recovery work, check the valves to

be controlled during the recovery work by comparing them with the ones in the flow sheet, and clearly

note the valves to be operated, other connected devices, and tubes on the flow sheet.

Two flow sheets must be prepared, i.e., one at the foreman and the other for posting in the workplace.

In addition, prepare a work procedure document for the refrigerant recovery work to reflect the actual

conditions of the workplace, and sufficiently share the work details among all the coworkers through

checking and confirmation before actually starting the work.

The gas mask and other protective gears required at each stage of refrigerant recovery work must be

prepared before starting the work.

Before the work, be sure to check and communicate the work details and procedures

among all coworkers, and carry out hazard prediction activities based on the

information shared. Neglecting to do this will increase the risk of on-the-job accidents

and injuries to a considerable level.

All the valves that have been opened or closed during the work must be prevented from

accidental operation through proper lock-out and tag-out procedures.

If the lubricating oil used is compatible with the ammonia refrigerant, a large amount of refrigerant

should be contained in the oil. Accordingly, after the refrigerant has been recovered once, the

refrigerant contained in the oil will be evaporated to increase the pressure inside the crankcase. As

such, be sure to recover the refrigerant repeatedly for a few times, until the pressure becomes low and

no more increased.

After completing the recovery work, shut down the related drive power and control power, and securely

carry out the lock-out and tag-out procedures.

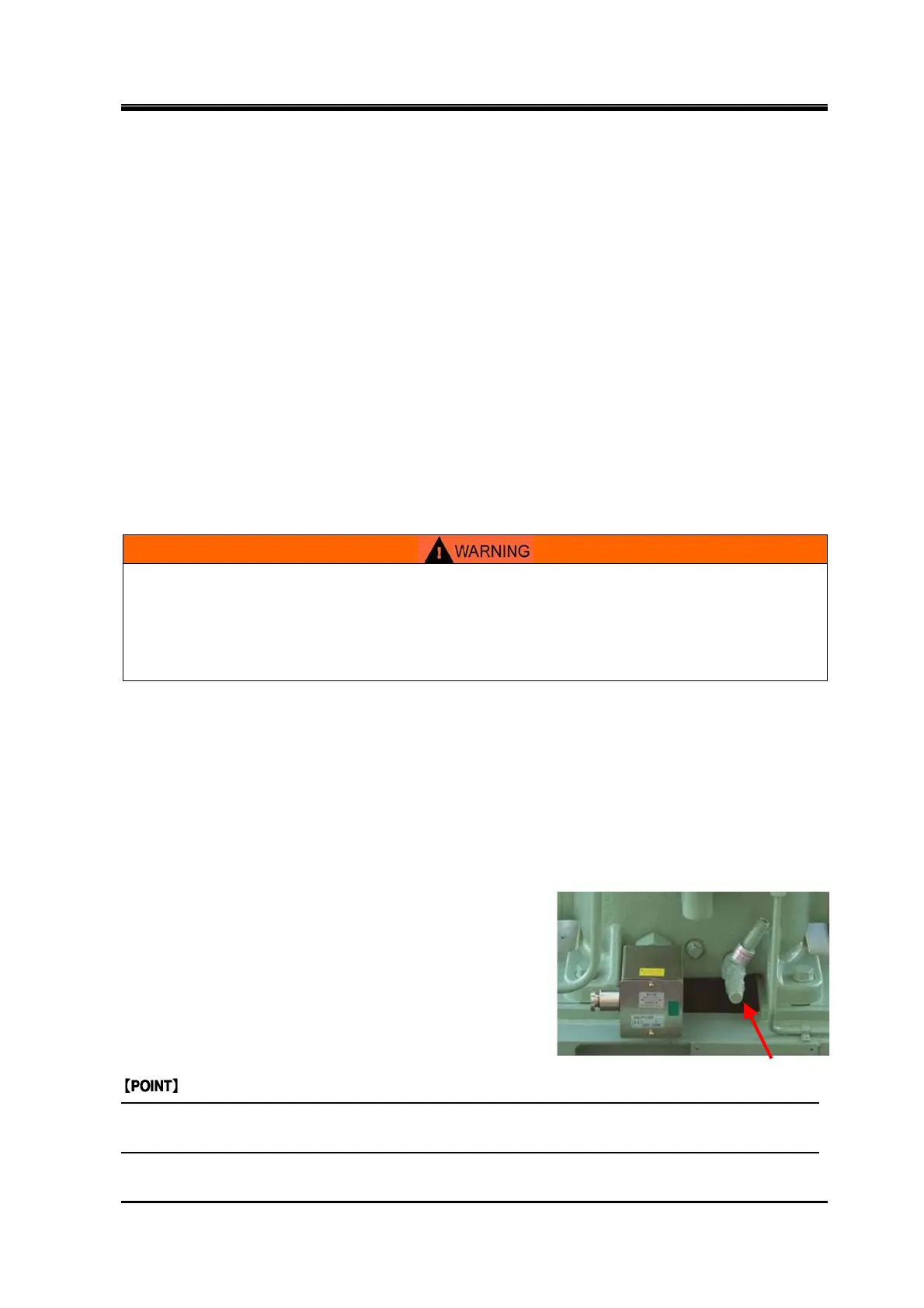

5.3.2 Draining the Lubricating oil

As soon as the refrigerant recovery work is completed, drain

the lubricating oil remaining in the compressor crank case [1].

Connect a hose of pipe to the oil supply and discharge valve

located at bottom left of the compressor oil pump, and drain

the lubricating oil into a container. Applying a pressure of 0.1

MPa or so by using nitrogen gas or dry compressed air

makes the draining easier. If the pressure is applied, be sure

to vent the gas to bring the pressure back to the atmospheric

pressure after draining the lubricating oil.

Oil Supply and Discharge Valve

When performing overhaul only motor jacket block described in Section 5.3.1.1, draining the

lubricating oil is not required.

Loading...

Loading...