2200Q2JE-HO-KHM-N_2015.02.

Chapter 5 Maintenance and Inspection

Ammonia Semi-hermetic Motor with K-series Compressor 5.1 Precautions for Maintenance

5-11

Table 5-4 Mass of the Motor Rotor

5.3.8 Motor Rotor

a) Likewise the case of motor casing, prepare the

set-up to lift up the motor rotor [607] by using

a crane or chain block and hooking the lifting

tool.

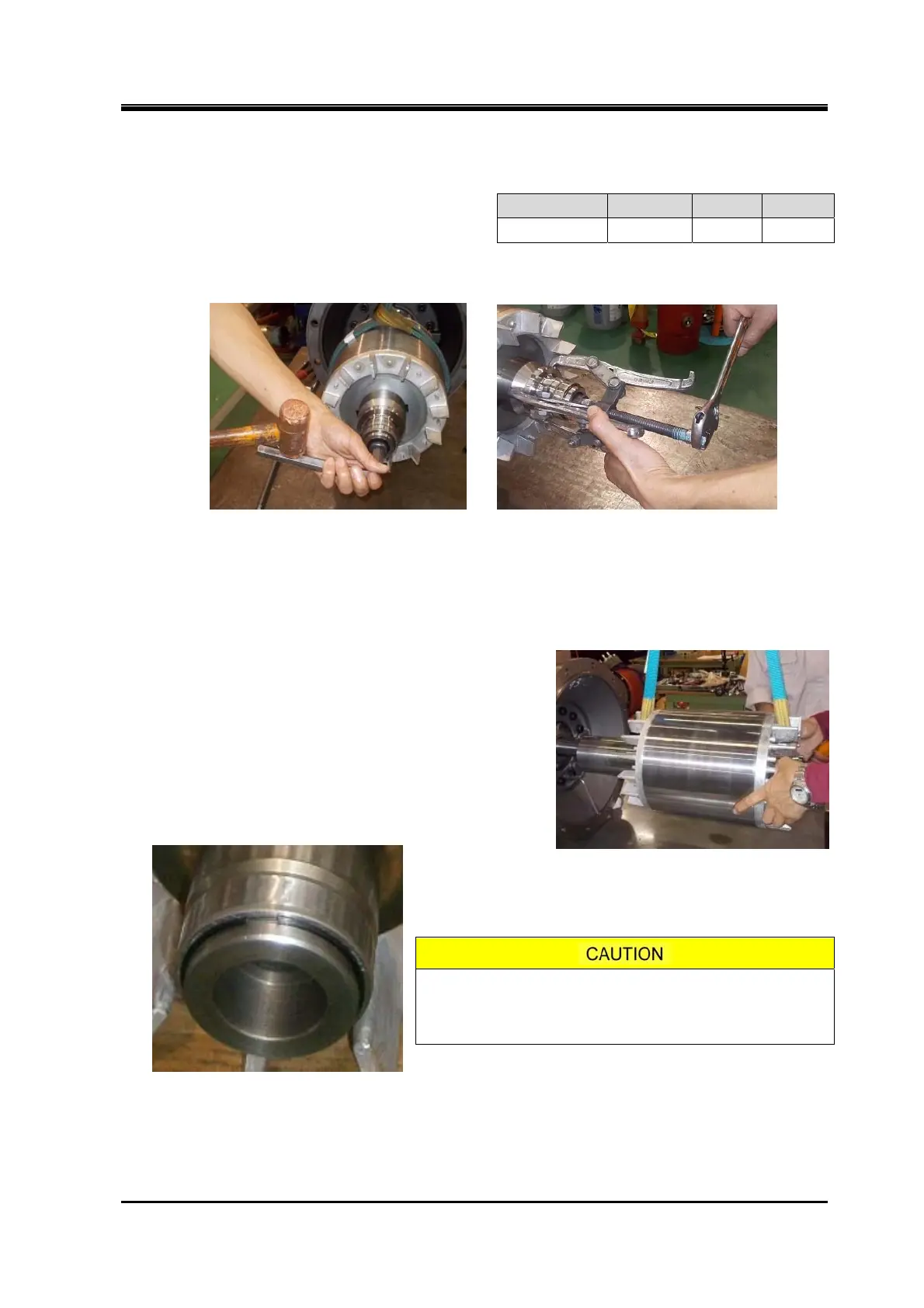

b) Loosen the motor rotor mounting bolt [609] at the end of the motor rotor shaft (following picture to

the left). Keep the bolt loosed to an extent of about three turns.

c) Use a pulley extractor to take off the motor rotor from the compressor shaft [2]. Hook the claw of

the pulley extractor at the flange of the motor rotor bushing [608], with the tip of the extractor

jacking bolt in contact with the head of the motor mounting bolt (see the above picture to the right).

d) While screwing the jacking bolt of the pulley extractor, the joint of compressor shaft and motor rotor

bushing is disengaged. Since the compressor shaft is tapered, once the tapered section is

disengaged, the shaft can be readily withdrawn.

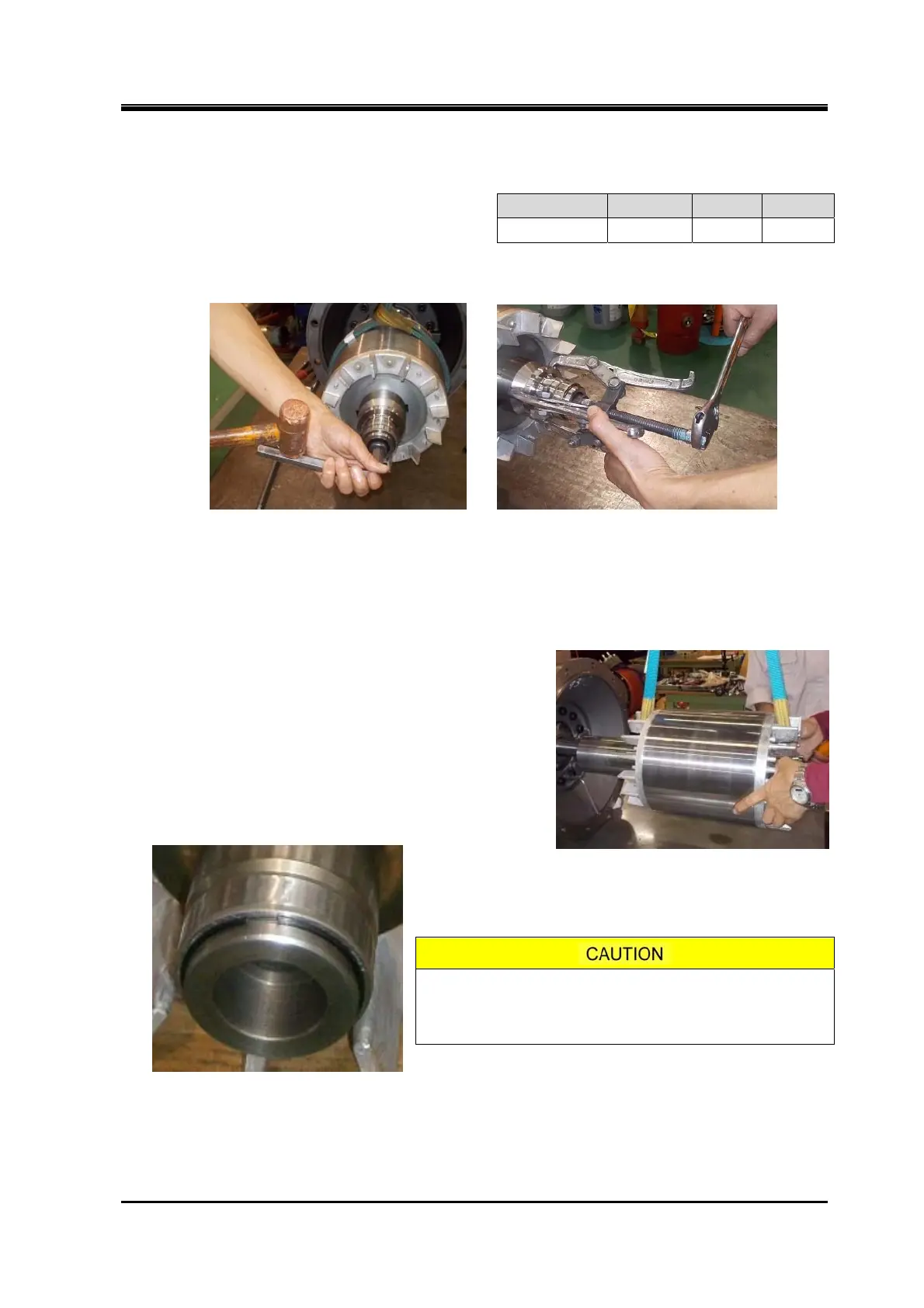

e) Take off the pulley extractor and try to lift up the motor

rotor liberated from the compressor shaft. Pull off the

motor rotor mounting bolt and pull the motor rotor toward

yourself to pull it off (picture to the right). The shaft is

attached with a key [4], which should be stored to

prevent from losing it.

f) At the end of the motor rotor bushing, the inner race of

motor bearing [613] is shrink fit (following picture). As

long as the bearing does not show any particular

abnormality, there is no need of removing it.

When replacing the bearing, remove the snap ring B [613-2]

that is fit in front for retaining the motor bearing, and heat up

the outer circumference of the inner bearing race with a gas

torch or the like to remove it.

Motor Model NHM30 NHM30 NHM30

Mass (kg) 60 80 120

● When pulling off the heated inner bearing race,

use a pair of thick leather gloves to prevent

your hand from a burn.

Loading...

Loading...