7-MAINTENANCE

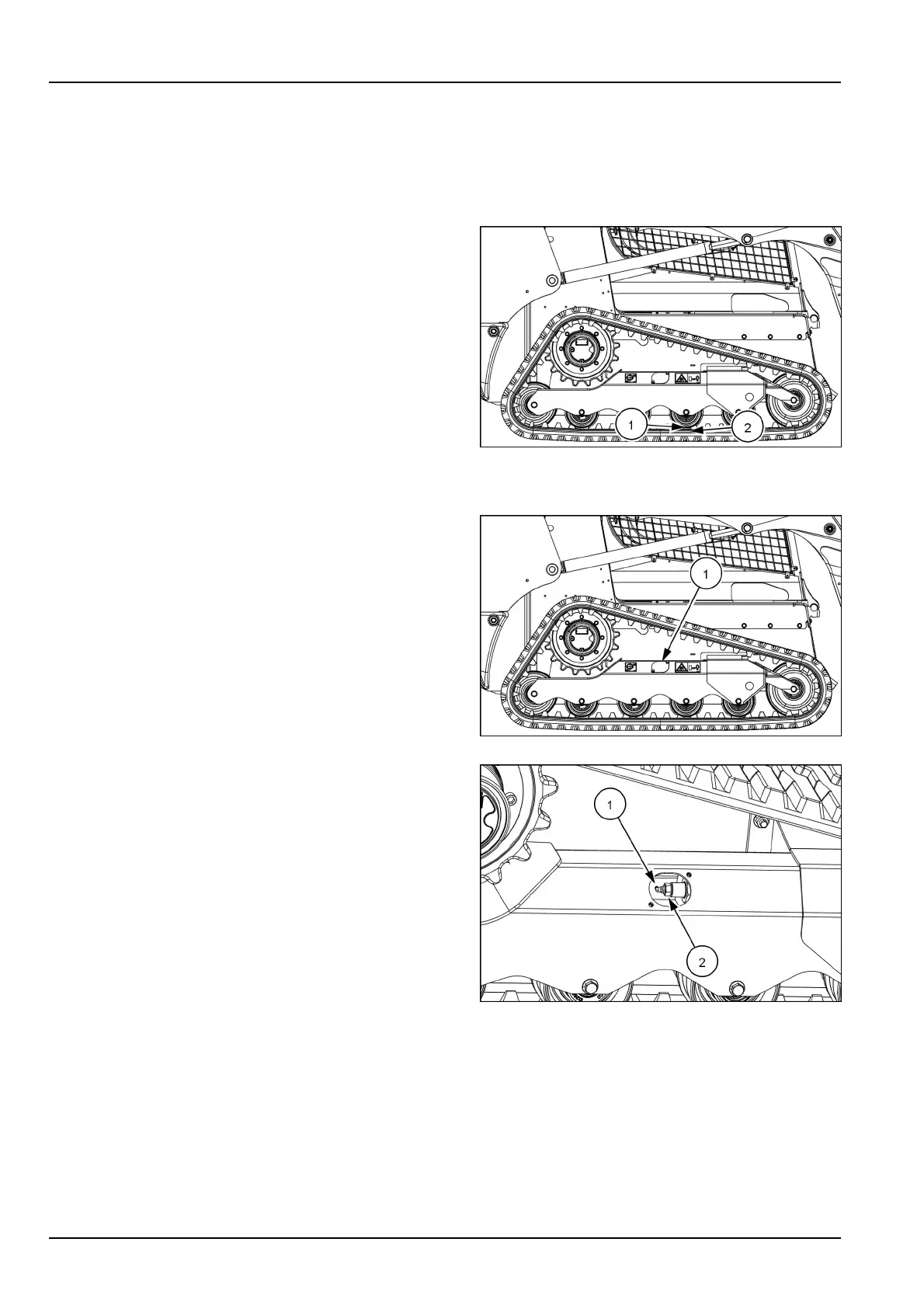

Tracktensioncheck

Checkthetracktensionevery50h.Forthisprocedure,thetracks,rollers,idlerwheels,debrisguard,andnaldrive

sprocketsmustbecleanofdirtanddebris.

Tracktensioncheck

1.Parkthemachineonrmlevelsurface.

2.Raise,block,andsupportmachineproperlyuntilthe

tracksareabout50mm(2.0in)offthesurface.

3.Measurefromthebottomofthecenterrollerwheel(1)

tothelowertracktopsurface(2).Theallowabletrack

sagis12–19mm(0.5–0.75in).

RAIL15SSL0356AA1

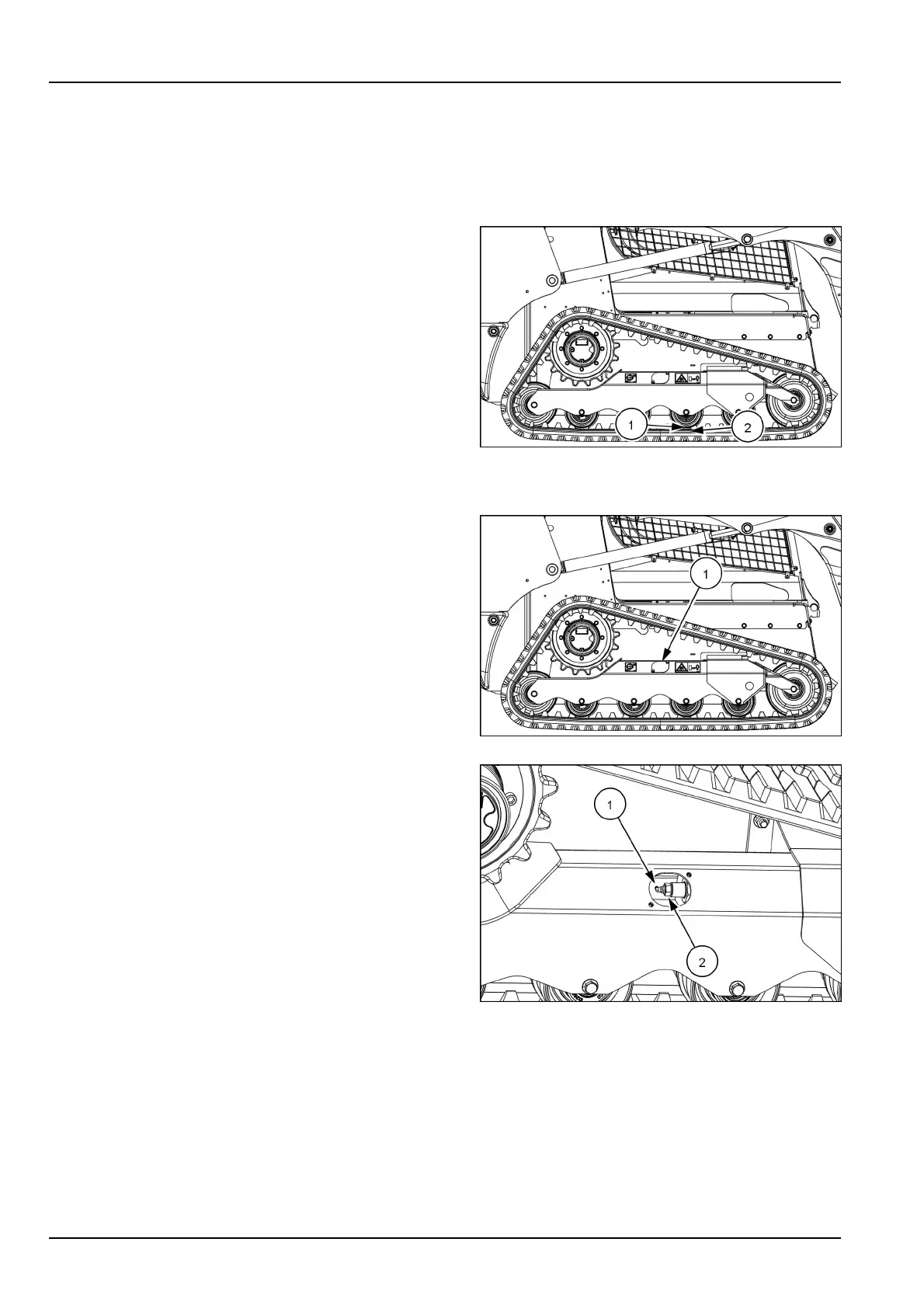

Tracktensionadjustment

1.Usea13mmtoolandremovethetrackadjustment

accesscover(1)toexposethetrackadjustmenttting.

RAIL15SSL0356AA2

Increasetracktension:

AddTUTELAMOL YGREASEGR-75greasetoin-

creasetracktensionadjustmenttting(1).

Decreasetracktension:

Usea19mmtoolandslowlyturnthetting(2)

counterclockwise.Greasewillescapefromthe

bottomofthettinganddecreasetension.

RAIL15SSL0382BA3

7-44

Loading...

Loading...