6 – English

EN

If the drive has been installed rotated by 180° (upside down), the door must

nonetheless open when OPEN is pressed; if it does not, set parameter 75 to 2.

The two emergency limit switches must be corrected so that they trip after the

operating limit switches.

Command Wire Motor

X2 - J11/U 1 U

X2 - J11/V 2 V

X2 - J11/W 3 W

X2 - J10 Bridge -

X7 - MiniFit Grey AMP 3 connector

X7 - MiniFit Green AMP 4 connector

X7 - MiniFit White AMP 2 connector

X7 - MiniFit Pink AMP 5 connector

X7 - MiniFit Yellow AMP 6 connector

X7 - MiniFit Brown AMP 1 connector

Bottom deactivation position

To adjust the bottom deactivation position limit switch, proceed as follows:

Move the door to the desired CLOSED position.

Set the switching cam 3 E↓(white) to trip the limit switch.

Tighten down mounting bolt A.

The adjustment is made with bolt B.

Move the door to the desired OPEN position.

Set the switching cam 1 E↓(green) to trip the limit switch.

Tighten down mounting bolt A.

The adjustment is made with bolt B.

Safety limit switches 2 SE↓ and 4 SE↑ (red) must be set to trip immediately after

the control limit switch.

Safety limit switches 2 SE↓ and 4 SE↑ (red) are factory set, close to the

operating limit switch.

After the operating test, check the seat of the mounting bolt.

Additional limit switches 8 P2↓ and 7 P2↑ are voltage free closing contacts,

while additional limit switches 6 P1↓ and 5 P1↑ are voltage free switching

contacts.

• In automatic operation, limit switch 6 is used as a pre-limit switch. It

must be adjusted to trip at 5 cm off the ground.

• In hold-to-run mode, it need not be adjusted and be used as a voltage

free contact.

Mechanical limit switches

small type large type

16

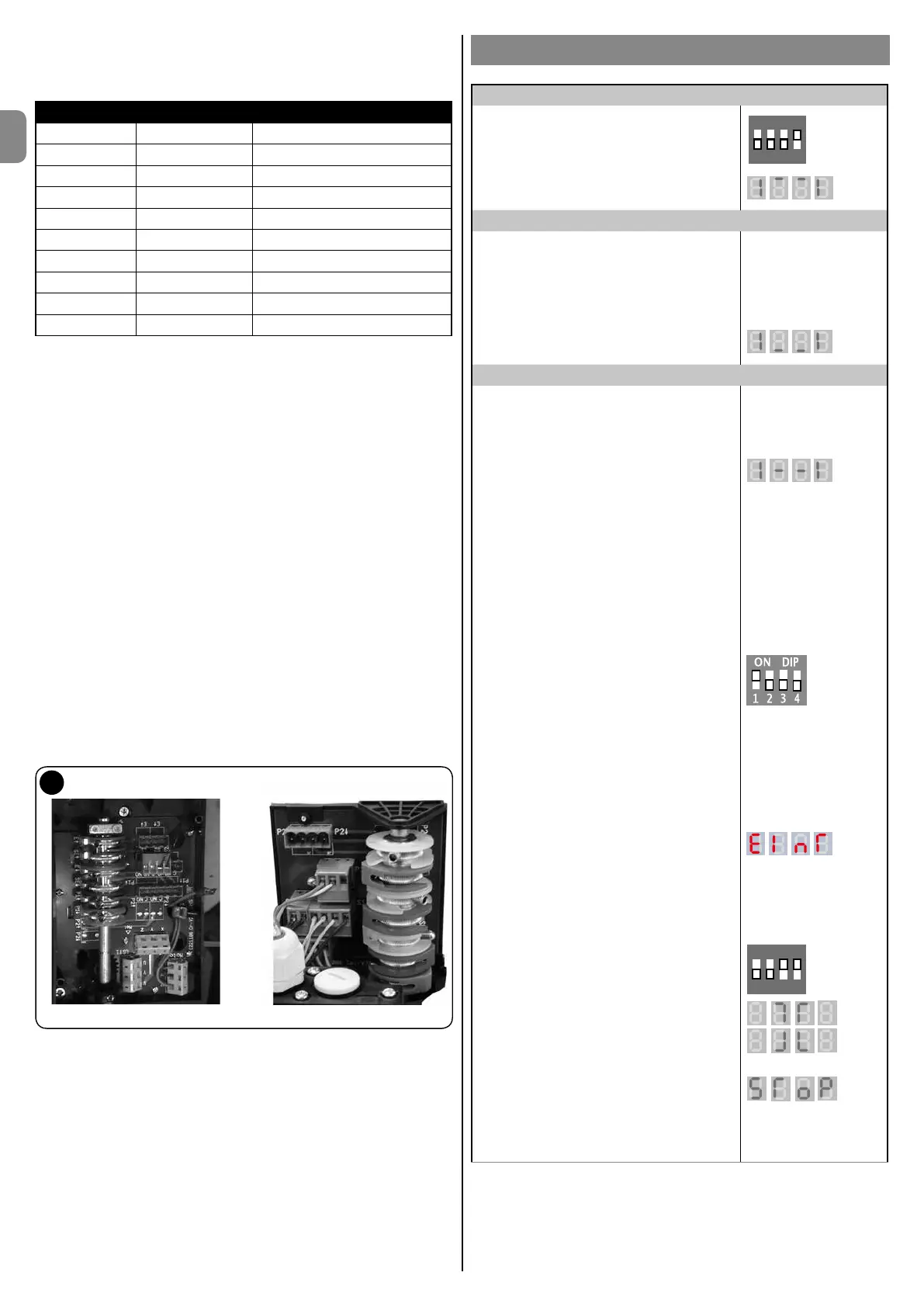

The subsequent paragraphs highlight the main programming functions of the

D-PRO Automatic control unit accessible through the dip-switches.

For further details on the available functions, please consult the 'D-PRO

Automatic parameters and error list' addendum accompanying this manual.

ADJUSTING THE DIGITAL LIMIT SWITCHES

Adjusting the end positions

To this end, set dipswitch 4 to “ON”.

ON

SAB

The upper sections of the display will ash.

Adjusting the top end position

Use the OPEN and CLOSE buttons on the

cover of the control unit's housing in hold-to-

run mode to move the door to the top end

position. Save this position by briey pressing

the OPEN or CLOSE programming button on

the front board.

The lower sections will now ash.

Adjusting the bottom end position

Use the OPEN and CLOSE buttons on the

cover of the control unit's housing in hold-to-

run mode to move the door to the bottom end

position. Save this position by briey pressing

the OPEN or CLOSE button on the front board.

The central sections will now ash.

If you do not wish to set any intermediate

position, set dipswitch 4 to OFF!

Partial open

If you wish to set a partially open position, leave

dipswitch 4 set to ON.

Use the OPEN and CLOSE buttons on the

cover of the control unit's housing to set the

desired partially open position; conrm and

save it with the OPEN or CLOSE buttons on the

front board.

The display now vanishes.

Now set dipswitch 4 to “OFF”.

The display will now ash Einr!

Press the OPEN button on the cover to enable

recognition mode; the door will move repeatedly

to the top end position and, after a brief pause,

to the bottom end position. The Einr display will

now disappear!

Maketheneadjustmentsusingthelistof

parameters.

Parameter 10 = top end position adjustment

Parameter 11 = bottom end position

adjustment

Parameter 12 = partially open position

adjustment

Modifying the direction of rotation of the

encoder

DIP 3 and 4 to ON = display direction of rotation

ON

1

SAB

2 3 4

DIP 3 and 4 to ON + OPEN button = modify

direction of rotation in one direction

DIP 3 and 4 to ON + CLOSE button = modify

direction of rotation in the other direction

Alternatively, the encoder's count direction can

be modied with parameter 75.

All dipswitches to OFF = display STOP

Loading...

Loading...