English – 5

EN

BASIC PROGRAMMING

It is necessary to set and store the most important parameters

before putting the loading ramp into operation.

Keep the

Ramp button pressed and at the same time enable the

main switch to enter the basic Programming mode.

After about 4 seconds the message 026 appears on the display;

now also press the button

R

. After pressing the button

R

, release

the button

and then also release button

R

.

Now the version of the program also briey appears on the display,

followed by the set valve program (P1, P2, etc.) and/or by the

appropriate test Program.

Use the Ramp button to set the loading ramp type:

P11/P12 = ramp with hinged lip

(P12 = Ramp UP does not use the valve)

P13 = ramp with hinged lip (2 valves), automatic Ramp

DOWN

P21/P23/P25 = ramp with telescopic lip (2 valves), automatic

Ramp DOWN

P31 = ramp with telescopic lip (3 valves), automatic

Ramp DOWN

P32/P33 = forced Ramp DOWN

(P33 = hold-to-run)

When the correct loading ramp type is displayed, press button

R

to conrm (memorize).

You now enter conguration mode; the parameters display in

sequence. The sequence depends on the type of ramp, as follows:

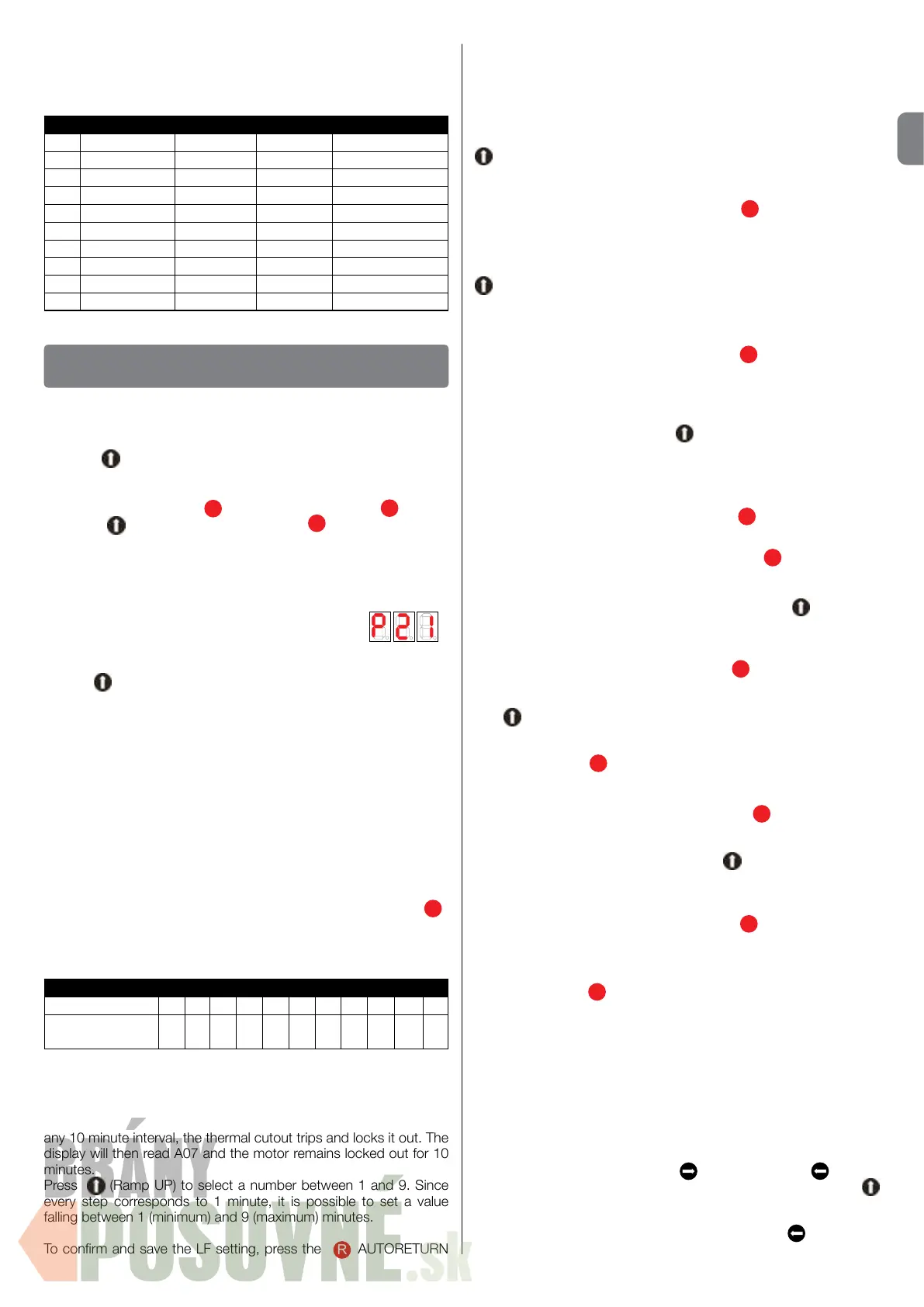

Table 2

P11-P12-P13 LF LE LA LN LR RB LC AR PC BU x

P21-P23-P25-

P31-P32-P33-TST

LF LE LA LN LR RB LC AR PC BU LL

The display now shows LF0.

This sets the hydraulic motor thermal protection - i.e. its maximum

use over a period of ten minutes; the default setting is 1 minute, so

that if the motor is run for 1 minute (even not continuously) within

any 10 minute interval, the thermal cutout trips and locks it out. The

display will then read A07 and the motor remains locked out for 10

minutes.

Press

(Ramp UP) to select a number between 1 and 9. Since

every step corresponds to 1 minute, it is possible to set a value

falling between 1 (minimum) and 9 (maximum) minutes.

To conrm and save the LF setting, press the

R

AUTORETURN

OPERATION WITHOUT CUSTOMISATION MODULE

button.

The display now shows LE0.

If the ramp is tted with a telescopic lip, this parameter sets the

minimum lip extension time. The main purpose of this setting is to

protect the legs supporting the lip (if present) against collision with

the base of the ramp itself. The basic time setting is 500 ms. Press

(Ramp UP) repeatedly to set a value of 1 to 9. Since every step

corresponds to 200 ms, it is possible to set a value falling between

500 ms (minimum) and 2.3 seconds (maximum).

To conrm and save the LE setting, press

R

AUTORETURN.

The display now reads LA0.

If the ramp is tted with a telescopic lip, this parameter sets the

maximum lip extension time; the default setting is 5 seconds. Press

(Ramp UP) to set a value of 1 to 9.

Since every step is equal to 1.5 seconds, it is possible to set a time

between 5 seconds (minimum) and 18.5 seconds (maximum).

To conrm and save the LA setting, press

R

AUTORETURN.

The next parameter is Ln0.

Here the maximum time of the difference between the retract and

extend movements of the telescopic lip is dened; the set basic time

is 0.5 seconds. By pressing the

(Ramp UP) button repeatedly,

now it is possible to select a number between 1 and 9. Since every

step corresponds to 0.5 seconds, it is possible to set a value between

0.5 seconds (minimum) and 5.0 seconds (maximum) hinged lip 2*Ln

on 1*Ln down).

To conrm and save the Ln setting, press

R

AUTORETURN.

The display now reads Lr0.

Lr is the ramp DOWN time in mode 00E

when

R

AUTORETURN

is pressed in 00E mode. In detail, it is the time employed by the

ramp in travelling from its maximum height to its standby position

(fully down). The basic time set is 5 seconds. Press

(Ramp UP)

repeatedly to set a value of 1 to 9. Since every step is equal to 1

second, it is possible to set a value between 5 seconds (minimum)

and 14 seconds (maximum).

To conrm and save the Lr setting, press

R

AUTORETURN.

We now set rb0.

Use

(Ramp UP) to select a value between rb0 and rb9, where

rb0 = gate deactivated and rb1-rb9 = gate active (with a gate active

time equal to the setting times 5, e.g. 9x5 = 45 seconds). To save

the setting, press

R

AUTORETURN.

The display now reads Lc0.

Lc is the Ramp UP time in mode 00C when

AUTORETURN is

pressed. In detail, it is the time employed by the ramp in travelling

from its minimum height to its standby position (fully down).

The basic time set is 3 seconds. Press

(Ramp UP) repeatedly

to set a value of 1 to 9. Since every step (number) corresponds to 1

second, it is possible to select a time between 3 seconds (minimum)

and 12 seconds (maximum).

To conrm and save the Lc setting, press

R

AUTORETURN.

The display now reads Ar0.

Ar can be set to either 0 or 1. These settings indicate the lack /

presence of the

R

AUTORETURN button on the control unit,

respectively. Do not modify the default setting.

The display now reads Pc0.

Pc has different functions depending on the type of ramp in use.

Ramps with hinged lip [P11 / P12 / P13]: Pc takes a value from 0 to

9 and indicates the sensitivity of the current measurement used to

detect the position of the lip while it is opening. It is used to detect

malfunctions during technical service and should not be modied.

Ramps with telescopic lip [P21 / P23 / P25 / P31 / P32 / P33]: Pc

affects the behaviour of the ramp and lip in the oating position 00A.

Pc0 the lip is locked since the

(extend lip) and (retract

lip) are disabled. To move it, you must rst raise the ramp with

(Ramp UP)

Pc1 the lip can always be extended or retracted, there is no need to

raise the ramp rst. The operation starts by pressing

(retract lip).

Pc2-Pc9 the lip can always be extended or retracted, but the ramp

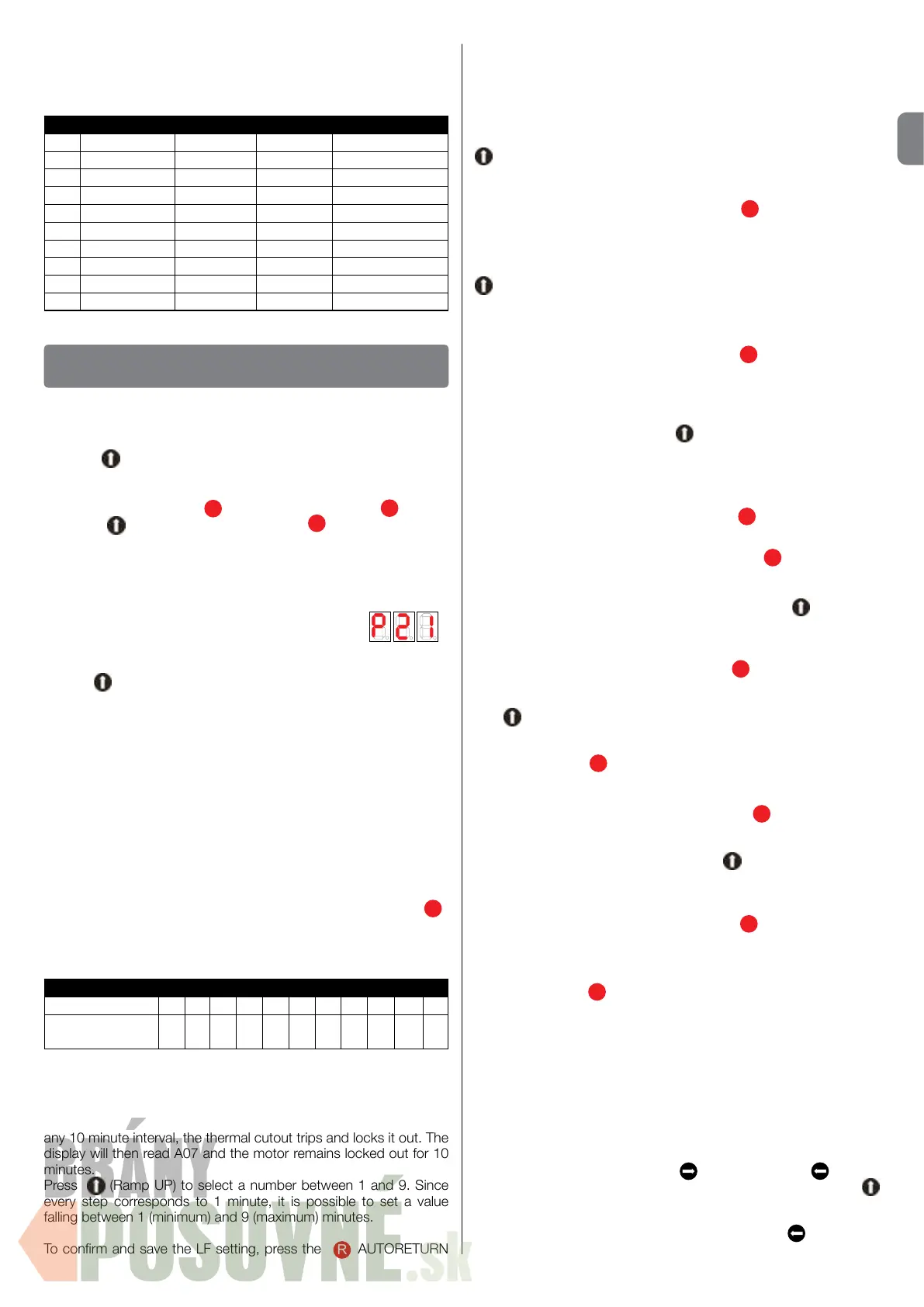

The following table illustrates the valve versions and their

operation for each type of ramp.

1,2,3 = number of valve

M = motor

Table 1

Ramp UP Extend Retract Ramp down

P11 1+M 1

P12 M 1

P13 1+M 1+M 1+2+M 1

P21 1+M 2+M M 1+2

P23 2+M M 2+M 1

P25 1+M M 1+M 2

P31 1+M 2+M 3+M 1

P32 1+M 2+M 3+M 1

P33 1+M 2+M 3+M 1

Loading...

Loading...