12 – English

EN

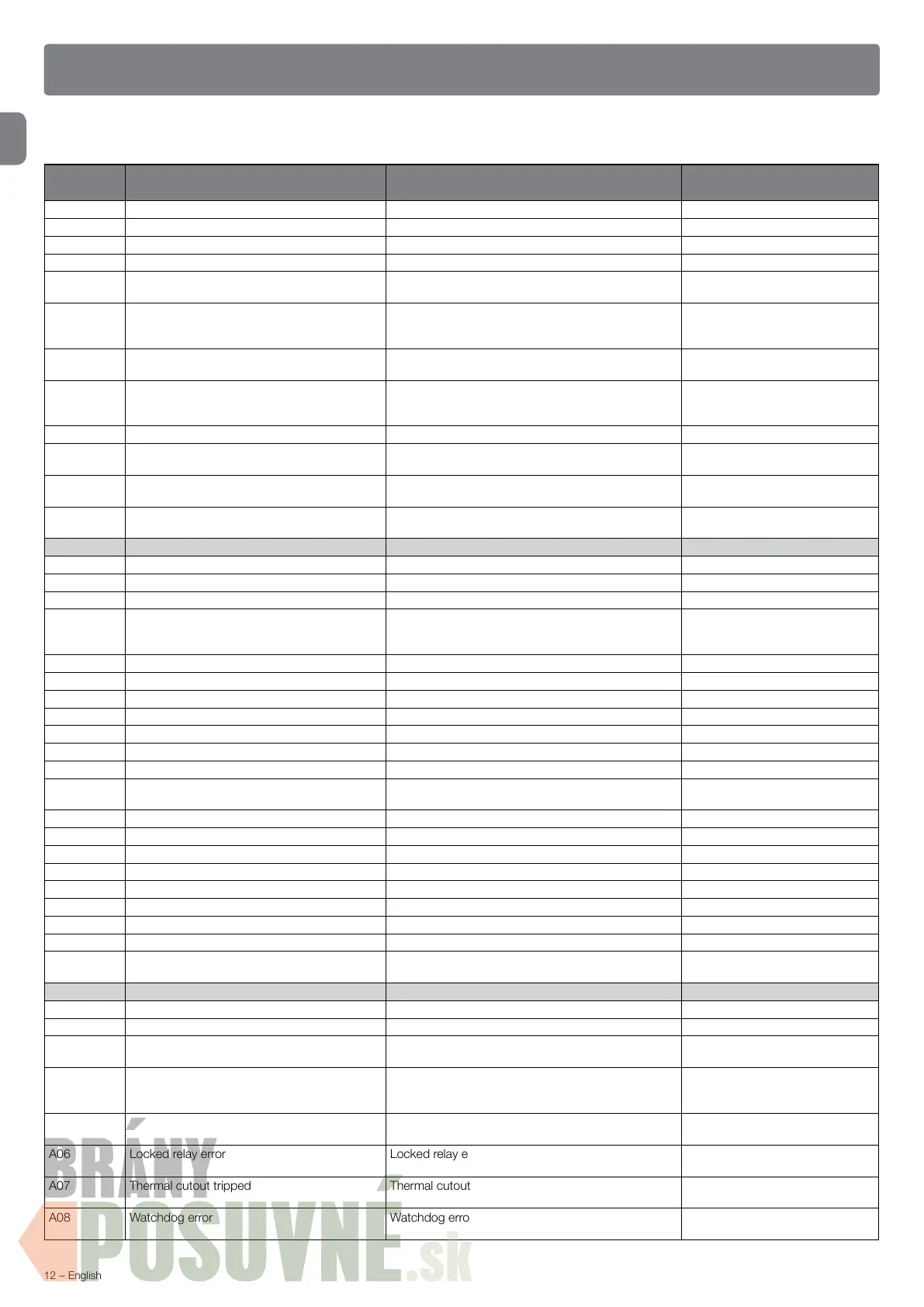

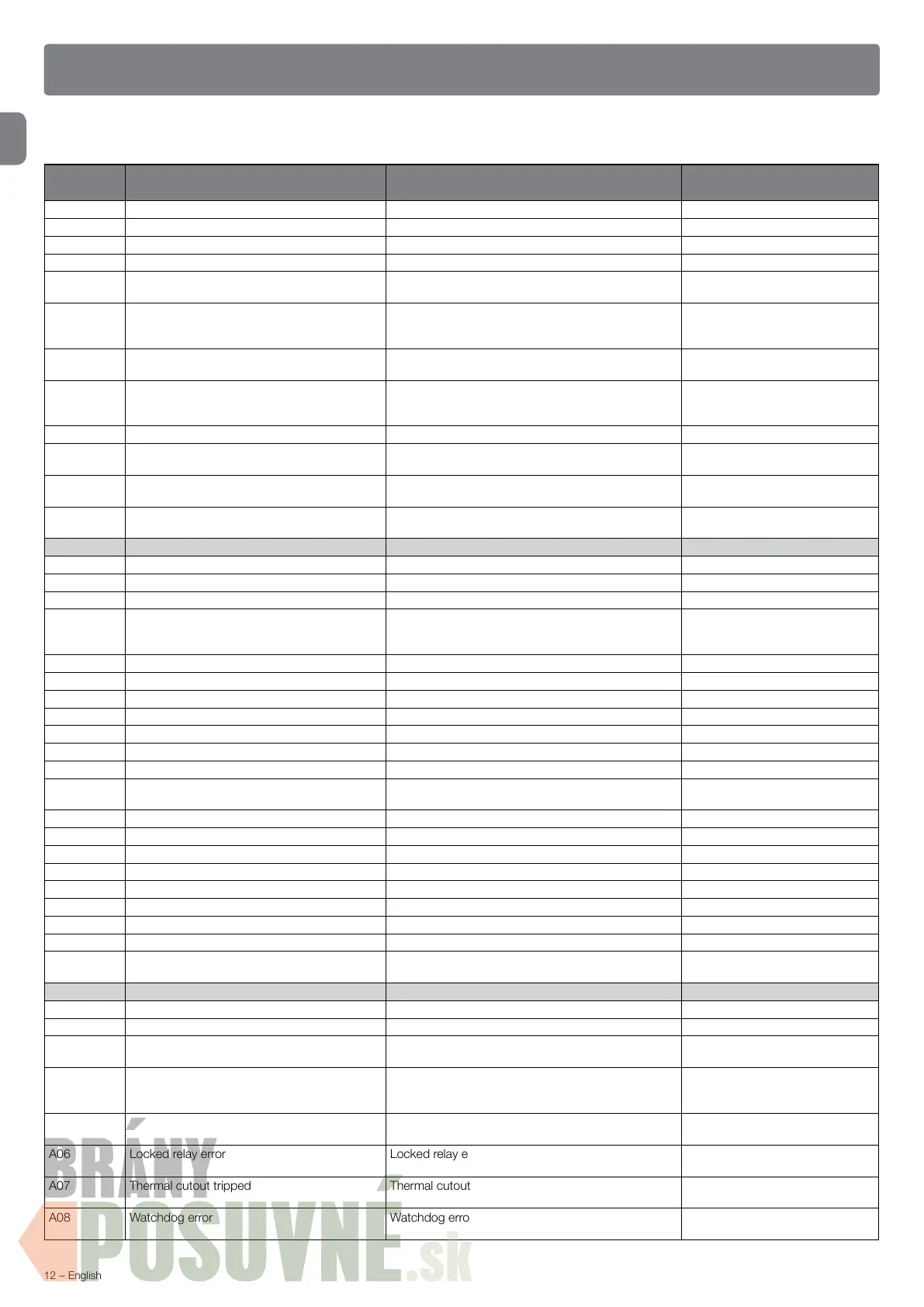

DIAGNOSTICS

This chapter covers the diagnostics for the UDL2 controller, with special reference to the 900 series rmware. We cover the meanings of the

display codes, which errors are displayed (their meanings and how to reset them) and the operation of the tSt program.

Code on

display

Programs for ramps with hinged lips (P11

– P12 – P13)

Programs for ramps with telescopic lips (P21 –

P23 – P25 – P31 – P32 – P33)

Note

P… Valve setting. P1x = single-valve ramp Valve setting. P2x, P3x = two/three valve ramp.

LF Sensitivity of electric motor thermal cutout Sensitivity of electric motor thermal cutout [min]

LE N/A Minimum telescopic lip extension time [s]

LA N/A Maximum telescopic lip extension time [s]

LN N/A Difference between telescopic lip retraction/extension

times [s]

During AUTORETURN, coincides

with status 00D

LR The time employed by the ramp in travelling

from its maximum height to its standby

position [s]

The time employed by the ramp in travelling from its

maximum height to its standby position [s]

Coincides with status 00E

RB Time available for industrial gate to close

before it is locked out [s]

Time available for industrial gate to close before it is

locked out [s]

If interlocking is implemented, this

coincides with status 00F

LC The time employed by the ramp in travelling

from its minimum height to its standby position

[s]

The time employed by the ramp in travelling from its

minimum height to its standby position [s]

Coincides with status 00C

AR Presence of AUTORETURN button Not used

PC Sensitivity of current measurement used to

detect the position of the lip while opening

Enables/disables the movement of the lip when it is

oating

In P31, one refers to status 00A

BU Determination of ramp operating mode and

number of available buttons

Determination of ramp operating mode and number

of available buttons

LL Not used Length of telescopic lip 5 = 500mm

1 = 1000mm

001 Auto-test 1 Auto-test 1

002 Auto-test 2 Auto-test 2

003 Auto-test 3 Auto-test 3

004 Ramp waiting to be enabled Ramp waiting to be enabled Waiting to detect vehicle / chock

positioning / industrial door

opening

005 Ramp enabled Ramp enabled Ramp ready to move

006 Ramp UP Ramp UP After 2s changes to status 007

007 Rotation of hinged lip Ramp UP

008 N/A Extension of telescopic lip

009 Lip fully open and Ramp DOWN Ramp DOWN

010 Shelter / chock / vehicle detectors still active Shelter / chock / vehicle detectors still active

011 Anti-collision function tripped Anti-collision function tripped Press AUTORETURN to quit

012 Incorrect oating position – the lip is properly

positioned on the vehicle

Incorrect oating position – the lip is properly

positioned on the vehicle

023 UDL2 controller rst startup UDL2 controller rst startup Press UP ARROW to continue

025 PEEP module programming PEEP module programming

026 Operating mode and parameter programming Operating mode and parameter programming

027 Display PEEP module programming (read only) Display PEEP module programming (read only)

00A Floating position correct Floating position correct

00C Ramp UP after AUTORETURN pressed Ramp UP after AUTORETURN pressed

00D N/A Retraction of telescopic lip

00E Ramp DOWN after AUTORETURN pressed Ramp DOWN after AUTORETURN pressed

00F The ramp has reached the base (standby

position) / waiting for industrial gate to close

The ramp has reached the base (standby position) /

waiting for industrial gate to close

If interlocking implemented

SEr Loading ramp full cycle counter Loading ramp full cycle counter Increments in status 00C

A01 RAM / ROM error RAM / ROM error

A02 Procedure error Procedure error e.g. chock removed during

loading/unloading

A03 Electric motor power fault Electric motor power fault e.g. three-phase not available /

star/delta connection incorrect /

insulation damaged / short circuit

A04 Locked button error Locked button error See paragraph Protection – no

counter for this error

A06 Locked relay error Locked relay error See paragraph Protection – no

counter for this error

A07 Thermal cutout tripped Thermal cutout tripped See paragraph Protection – no

counter for this error

A08 Watchdog error Watchdog error See paragraph Protection – no

counter for this error

Loading...

Loading...