Pump

B 2-3

E 2000 Nordson Corporation

All rights reserved

41-3000

Issued 11/00

B2EN-02-[3-PUMP]-5

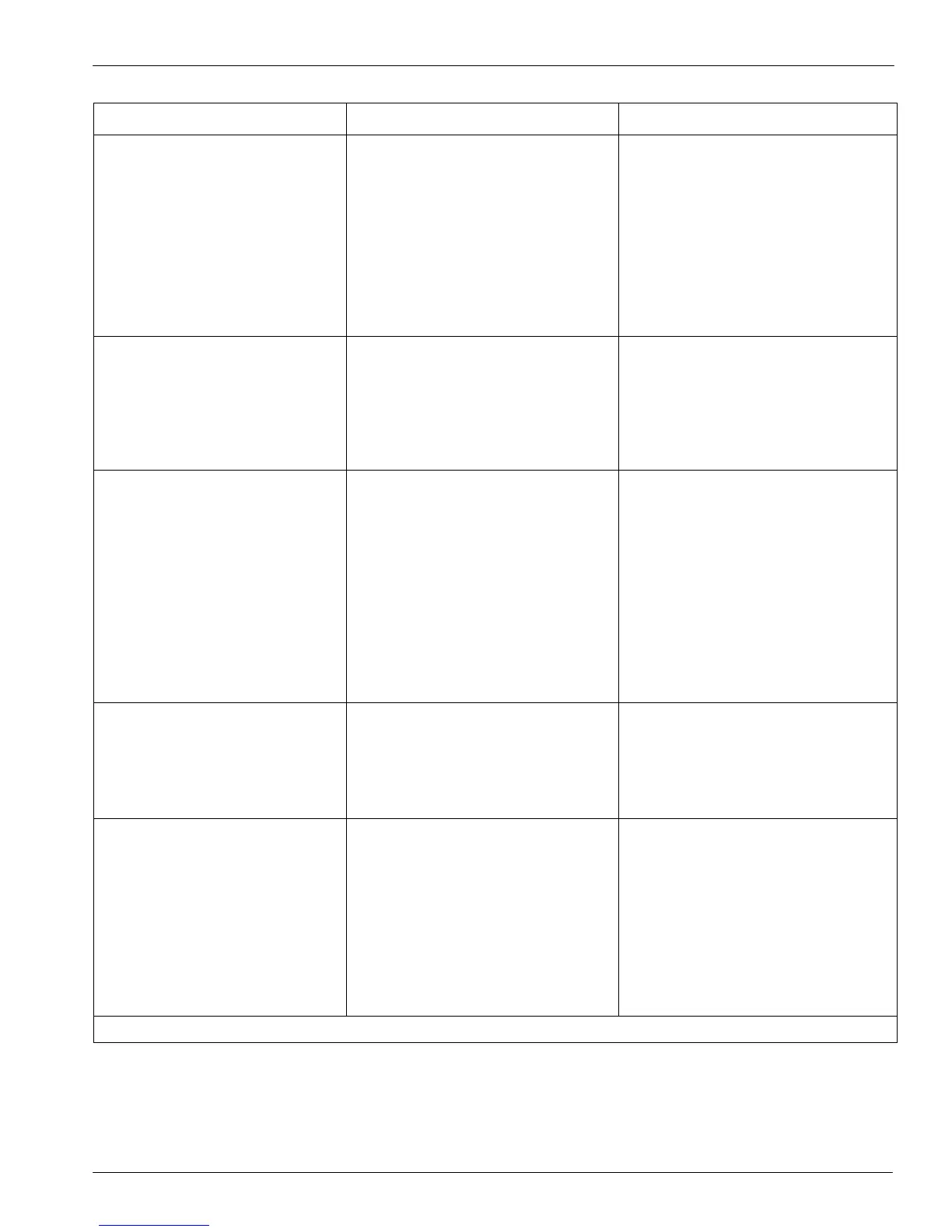

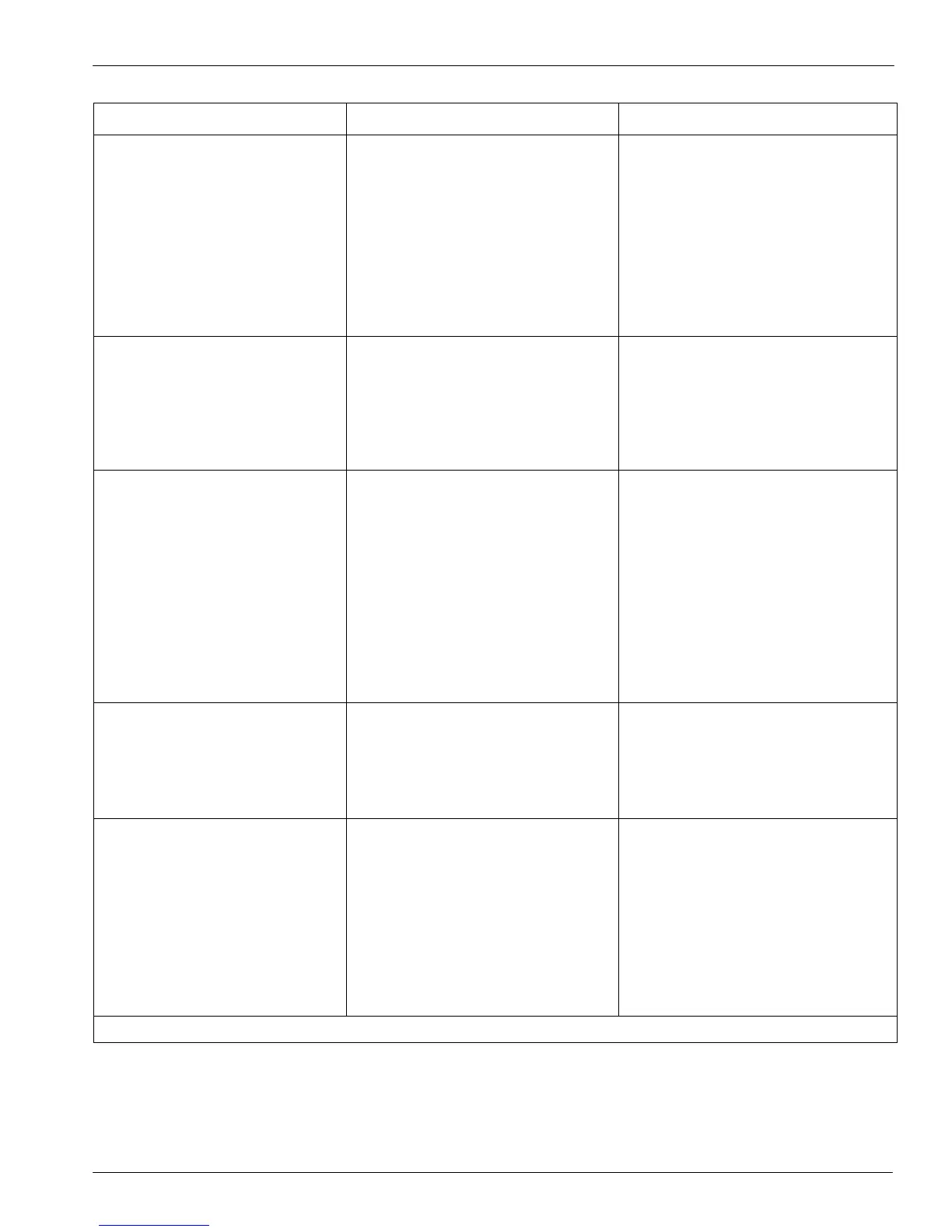

Problem Possible Cause Corrective Action

2. Wavy beads Adhesive too cold Check the tank, hose, or gun

temperature setpoints and adjust

them as necessary.

Ambient temperature below freezing

or guns subject to draft

Protect the melter and guns from

freezing temperature conditions and

drafts.

Nozzles too far from product Position the guns so the nozzles are

no more than 13 mm (0.5 in.) from

the product.

3. Excessive adhesive at

beginning of bead

Nozzles too far from product Position the guns so the nozzles are

no more than 13 mm (0.5 in.) from

the product.

Nozzles partially clogged Clean the nozzles. Refer to the

nozzle cleaning procedure in the gun

manual.

4. Adhesive stringing Nozzle too far from product Position the guns so the nozzles are

no more than 13 mm (0.5 in.) from

the product.

Adhesive too viscous Change to a compatible

lower-viscosity adhesive.

Adhesive too cold Check the tank, hose, or gun

operating temperature setpoints and

adjust them as necessary.

Adhesive old Do not exceed the recommended pot

life of the adhesive.

5. Concentric circles in bead Adhesive too hot Check the tank, hose, or gun

operating temperature setpoints and

adjust them as necessary.

Adhesive not viscous enough Change to a compatible

higher-viscosity adhesive.

6. Adhesive bouncing or

splashing from product

Adhesive too hot Check the tank, hose, or gun

operating temperature setpoints and

adjust them as necessary.

Adhesive not viscous enough Change to a compatible

higher-viscosity adhesive.

Nozzle orifice too large for

application

Change to a nozzle with a smaller

orifice.

Too much hydraulic pressure Decrease hydraulic pressure.

Continued on next page

Loading...

Loading...