75

Circuit Board Replacement

When a circuit board is replaced, data must be transferred from the old board, otherwise

remote controller and the unit will not operate.

After installing the new circuit board, please transfer data according to the following procedure:

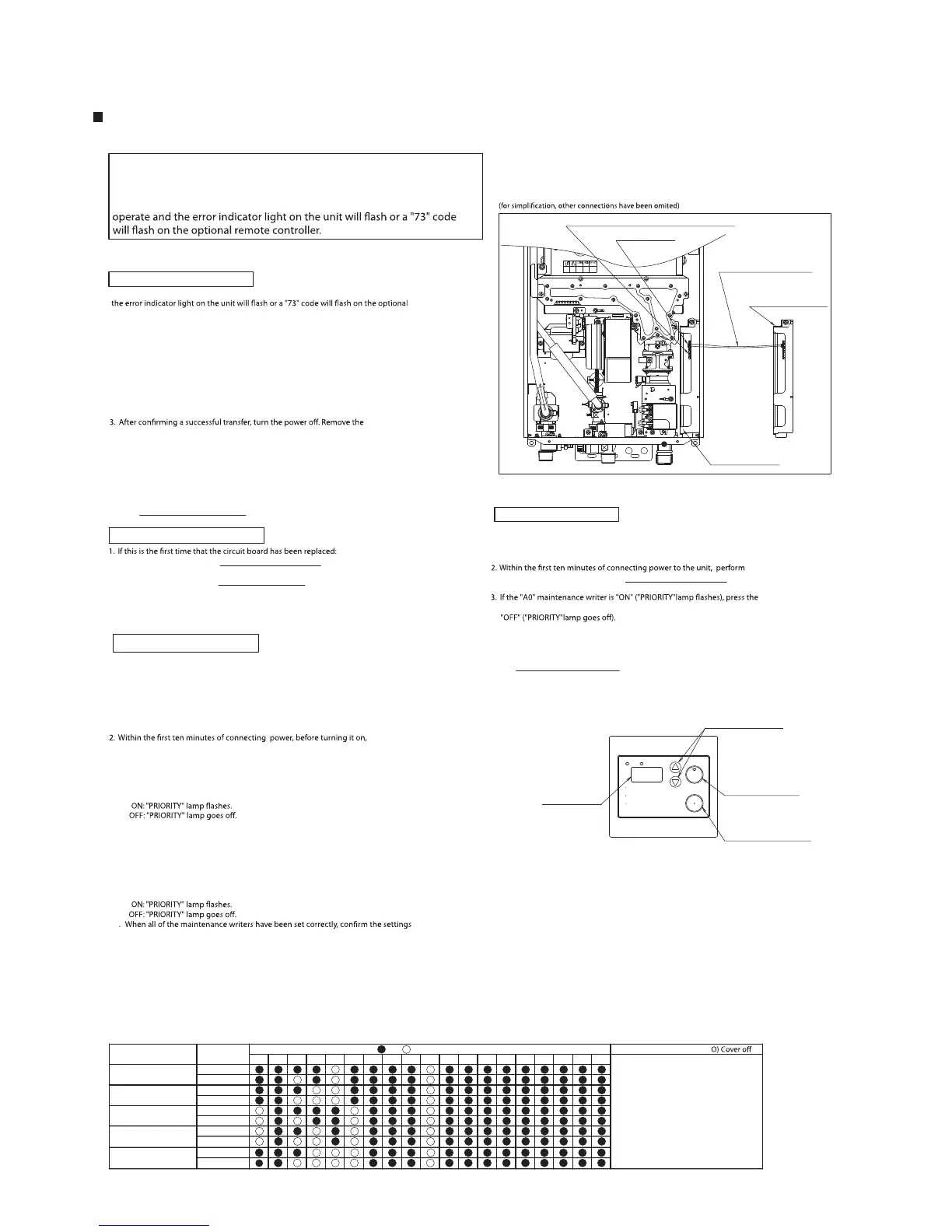

1. With the electrical power disconnected, connect the new and old

circuit boards by inserting the supplied data transfer wire into

connection number CN75 (see Note 1) of each circuit board. If a temperature

selection wire is inserted into CN75 on the old circuit board, remove this

connector and save it for the new circuit board.

The unit will signal a successful transfer by rotating the fan and opening and closing

the gas solenoid valve (3 minutes).

cable connecting the new and old circuit boards.

4. If a temperature selection wire was removed from the old circuit board, reinsert it into CN75

on the new circuit board.

* Be sure to read.

It is necessary to transfer data when replacing a circuit board. Vital

information about the water heater such as the settings and unit history

will have to be written to the new board. Please transfer data using the

following procedure. If the transfer is not successful, the unit will not

Data Transferring Procedure

Note 1. The data transfer wire is marked "89", but please connect it to connection number CN75.

2. If this is the second time that the circuit board has been replaced:

* If data has already been transferred to the board, follow the resetting procedure.

* Once data has been transferred to a new board, the transfer procedure cannot

be performed again.

Initial Circuit Board Settings

are made before making the initial circuit board settings.

Reference connection diagram

1. Install the circuit board into the unit and make all wiring connections.

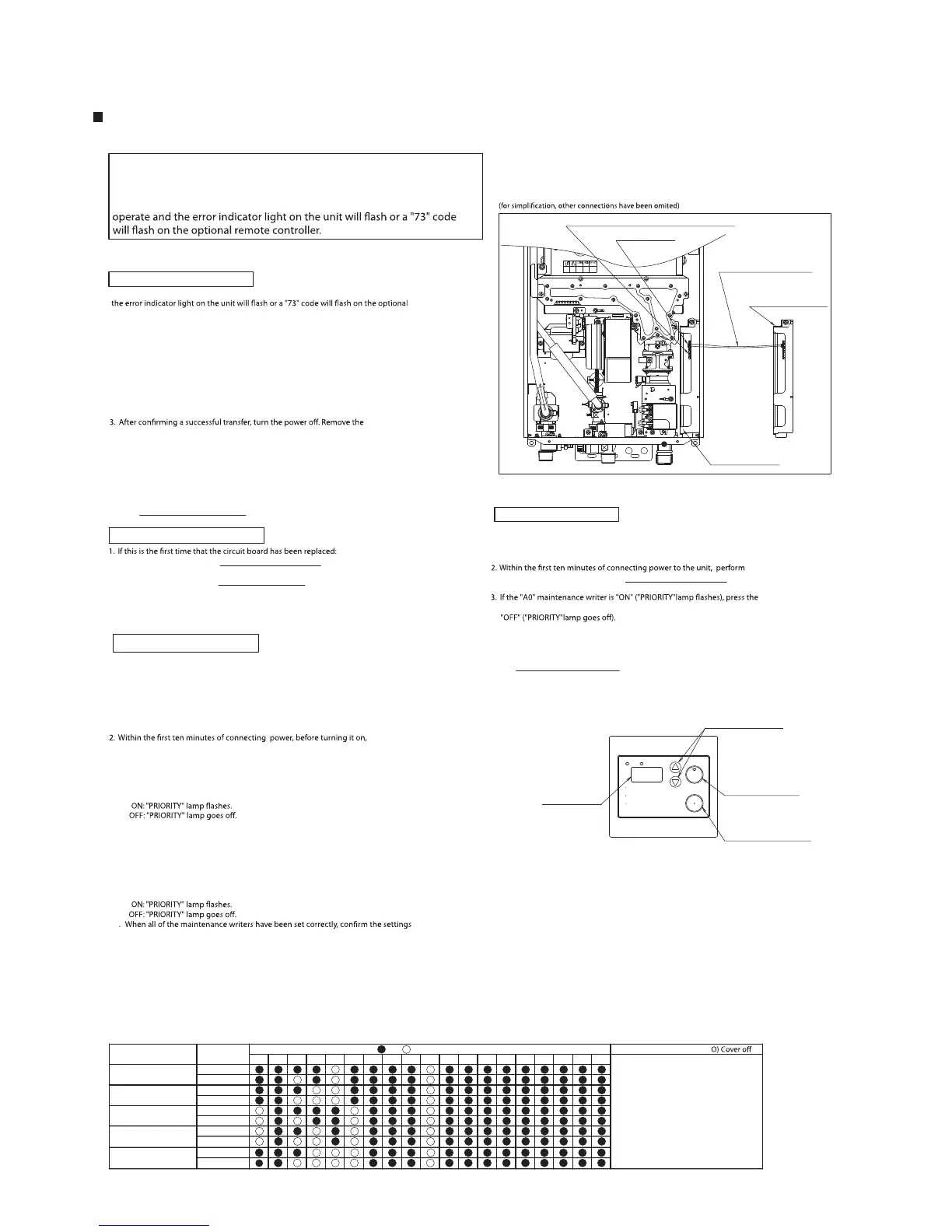

"FLOW METER ALARM SET" button for 0.5 seconds to change "A0" to

4. Press and hold both the "up" and "down" buttons on the remote controller

is not done.

the "Data Transferring Procedure".

Circuit Board Resetting

Setting Button

(Swiching ON/OFF)

Please read instructions carefully

Check actual and controller water

Hot Water Heater temperature

over 125 °F can cause severe burns

WARNING

temperature before entering shower

before using this appliance.

Display

Setting Button

DOWN

BURNER ON

PRIORITY

°

F

gal.

POWER

ON/OFF

UP

FLOW METER

ALARM SET

Operation Button

RC-7649M

or bath.

instantly or death from scalding.

1. Connect electrical power to the unit and wait ten seconds before proceeding to step 2.

hit the "up" or "down" button on the remote controller and hold until the display

blinks "99". If the unit does not go into maintenance mode, unplug the unit and

try again.

3. Use the "up" or "down" button on the remote controller to change the maintenance

5. Change "1F" from OFF to ON. (for NR50-OD, NR71 (-SV,-OD) and N-0631S (-OD) models only)

7. Change "FE" and "FC" from OFF to ON in order to access the hidden maintenance writers.

6. Change "2B" from OFF to ON.

(Display blinks with "A0".)

8. Now the maintenance writers can be accessed by hitting the "up" or "down" button

correct writer setting.

by pressing and holding both the "up" and "down" buttons on the remote controller

done.

Buttons for adjusting the manifold pressure settings

Connector Lead attached

with a New Circuit Board

for Servicing

Connector CN75

New Circuit Board

Old Circuit Board

16A

* After replacing the board, check and adjust manifold gas pressure settings to

listed in the "Setting list for Gas manifold pressures" table of the unit.

* When you cannot transfer data between the boards, please follow the procedures

Note: A remote controller may be necessary to complete the set-up

of the new circuit board.

controller before performing the below steps.

2. Reconnect the electrical power. The data transfer will be completed in about 30 seconds.

under "Data Transfer Troubleshooting".

Data Transfer Troubleshooting

Please follow the procedure "Initial Circuit Board Settings".

Please follow the procedure "Circuit Board Resetting".

* After replacing the circuit board, make sure all connections

* When the water heater has no remote controller, make sure to connect

a remote controller before performing the initial settings below.

4. Press the "FLOW METER ALARM SET" for 0.5 sec to change the setting ON/OFF.

* When the water heater has no remote controller, make sure to connect a remote

steps 1 through 4 and step 6 of the "Initial Circuit Board Settings" procedure. This

should result in "A0" blinking on the remote controller.

5. If this is a replacement board that had initial problems with data transfer, follow

until the controller emits a beeping noise. The new settings will be lost if this

[RC-7649M, RC-7650M]

(Changing Writer No.)

(Writer No.)

writer number.

on the remote controller. Refer to the "Setting list for DIP settings" table for the

9. Press the "FLOW METER ALARM SET" for 0.5 sec to change the setting ON/OFF.

10

until the controller emits a beeping noise. The new settings will be lost if this is not

Note 1. To cancel the settings, let the controller sit for 10 minutes,

or turn on the operation button. The information set previously

will be canceled. To change settings again, follow steps 1 through 9.

Note 2. Only change data as listed in the "Setting list for DIP settings" table.

Setting list for DIP settings

(check the rating plate for model and gas type)

<NR50-OD / NR66 (-SV,-OD) / N-0531S (-OD), NR71 (-SV,-OD) / N-0631S (-OD)>

Gas Type

Model

NR71-SV/N-0631S

NG

NG

LPG

LPG

A1 ABA9A7

NR71-OD/N-0631S-OD

B0 B1 B8AE

BE C3

AD B5 B7

C4C1

NR66-SV/N-0531S

NR66-OD/N-0531S-OD

NG

NG

LPG

LPG

1F 2B BCA8

Circuit board DIP setting ( :ON :OFF)

Manifold Pressure (inch H2

"Refer to Page.83 - 87"

NR50-OD

NG

LPG

Loading...

Loading...